| This TECH page covers much more than just replacing the injectors. When the injectors are being replaced for performance reasons (or just need to be replaced), there are a lot of other things that can be easily handled with the plenum off the engine. Injector replacement, PCV valve replacement, valve cover seal replacement, throttle body water jacket bypass, safety boost cut solenoid removal, plenum exchange, throttle body replacement and a little bit of painting are all covered on this page. I used Mike H's page from www.TTAZ.org (defunct) and JaimeZX's page that was based on Mike's page as references to put together this page.

This is on a 91 TT, the NA is similar enough to follow this document.

It should be obvious when something is not applicable to the NA.

Parts:

All links for parts go to CourtesyParts.com for on-line parts ordering.

There are two different styles of injectors for the 90-96Z. There is the pintle style (old) and the pintle-less style (new). Each has a different set of O-rings and insulators. The old style has a square electrical connector with a metal clip, the new style has an ovalish electrical connector with a built in plastic squeeze clip.

Old style injector

New style injector

For an injector replacement procedure with old style injectors:

14033-30P02 - plenum to lower intake gasket

16635-10V02 - upper injector insulator (6 req'd)

16635-10V10 - lower injector insulator (6 req'd)

16618-10V00 - lower injector O-ring (6 req'd)

16618-53J00 - lower injector O-ring (6 req'd)

16618-10V05 - upper injector O-ring (6 req'd)

A6440-N7685 - 5" bulk high pressure fuel hose (to connect the fuel rails)

14719-30P05 - EGR gasket (2 req'd)

For an injector replacement procedure with new style injectors:

14033-30P03 - plenum to lower intake gasket

16635-53J00 - upper injector insulator (6 req'd)

16635-88G00 - lower injector insulator (6 req'd)

16618-53J00 - lower injector O-ring (6 req'd)

16618-10V05 - upper injector O-ring (6 req'd)

A6440-N7685 - 5" bulk high pressure fuel hose (to connect the fuel rails)

14719-30P05 - EGR gasket (2 req'd)

If ordering stock injectors, also note the Z shipped with 'blue' or 'black' dotted injectors. All that is available from Nissan now is the 'black' dotted injector, whose part numbers have superceded both the 'blue' and 'black' dotted injectors over time. The difference between the two had to do with the spray pattern of the injector. I would *highly* recommend replacing all six injectors even if only one 'needs' replacing. Once one goes, the others have to work harder to make up for the lost output. Keep in mind all three cylinders in a bank feed a single O2 sensor... so when the ECU detects a lean condition because one injector in the bank is failing, it pours in more fuel to make up for it, so the engine really isn't running at an optimum self tuneable level. Generally when one injector fails, the others follow in short order.

16600-15V02 - NA old style injector 6 or 1 pieces

16600-10Y01 - NA new style injector 6 or 1 pieces

16600-40P07 - TT old style injector 6 or 1 pieces

16600-21U00 - TT new style injector 6 or 1 pieces

Optional:

11810-40P00 - PCV valves (2 req'd)

11823-30P01 - PCV hose

11823-30P11 - PCV hose

11826-30P10 - PCV hose (rear)

11823-40P01 - PCV hose (TT passenger front valve cover)

11823-40P11 - PCV hose (TT driver front valve cover)

11823-30P20 - PCV hose (NA passenger front valve cover)

11823-30P12 - PCV hose (NA driver front valve cover)

23785-40F00 - IAAC Gasket

14099-30P01 - Hose from IAAC to air regulator

14099-30P02 - Hose from air regulator to balance tube

14033-30P05 - Large balance tube O-ring (2 req'd)

14033-30P06 - Small balance tube O-ring (1 req'd)

22675-10Y00 - fuel pressure damper

22670-10Y00 - fuel pressure regulator

16440-30P01 - long fuel lines from filter and to fuel return (2 req'd)

A6440-N7685 - 22" total bulk high pressure fuel line for all fuel lines on top of the engine (includes 5" fuel rail connection listed in the top kit)

16400-Q0805 - fuel filter

24079-25P26 - harnesses with new injector connectors (2 req'd)

6' of 8mm (5/16") heater/fuel hose for TB bypass

3' of 6mm (1/4") vacuum hose for TB bypass

1' of 5mm (3/16") vacuum hose for TB bypass

6mm (1/4") hose barb (barrel) for TB bypass

5mm (3/16") hose barb (barrel) for TB bypass

M5 x 16 mm with .80mm pitch hex head socket screws (12 req'd)

Special Tools:

10mm stubby wrench

Procedure:

Removing the plenum

1. Relieve fuel pressure. Disconnect the negative terminal of the battery. Jack up the car. I prefer to lift the car up to me then have to bend over the whole time. There's a couple places a stepping stool might be required to reach the middle of the engine, but it's easier to bend over half as far 95% of the time and have to use a step in places then bending over 100% of the time. A service cover or fender cover is highly recommended.

|

|

|

2. Remove center trim cover (4 x 5mm Hex head bolts) (green dot in 1.).

|

1.

|

|

3. Disconnect throttle cables by loosening the front nuts on the bracket (2 x 14mm nuts) (yellow dot in 2.), then swing the cables out of the throttle body control rod cable ways in the front of the engine. The cables are held in place in three locations along the way to the plenum. Remove all of the holding tabs (3 x 10mm bolts). Remove the cruise control solenoid from the fender well (2 x 10 mm bolts). Swing the main throttle cable out of the way.

|

2.

|

|

4. Disconnect all the hoses to the balance tube on the back of the engine (5 for TTs, 4 for NAs) (yellow dots in 3. & 4.). Disconnect the wiring bracket on the passenger side of the plenum (1 x 10 mm). Remove the balance tube (3 x 12 mm acorn nuts, 2 x 12 mm bolts) (green dots in 3. & 4.). Be careful not to drop the O-rings that seal the balance tube to the plenum into the plenum (5. & 6.). Plug all three holes with rags to keep debris from getting in there (7.). Remove the wiring bracket from the plenum.

|

3.

4.

5.

6.

7.

|

|

5. Remove all upper fuel rail pieces. Refer to the fuel filter replacement page to see how to relieve fuel pressure. Spray all hose fittings with PB Blaster penetrating lubricant. This is the best product I have ever used for this purpose. Disconnect the small vacuum lines on the driver side (yellow dots in 8.). Disconnect the fuel lines from the upper fuel rail on the plenum (2 x phillips hose clamps) (green dots in 8.). Remove all of the bolts holding the fuel pressure regulator, fuel pressure damper, and upper rail itself from the engine (6 x 10 mm bolts) (green dots in 9. & 10.). Loosen whichever clamps are most convenient that are holding the pressure regulator and damper to the lower fuel rail (under the plenum). Remove the upper fuel rail, regulator and damper (most of 10.).

|

8.

9.

10.

|

|

6. Remove the coil packs by disconnecting the connectors to each one (yellow dots in 11.). The wires might be trapped by keepers. Remove the keepers (blue dot in 11.) and the oil cap (red dot in 11.) to get the wires pulled back. Remove the bolts holding the coil packs in place (12 x 12 mm bolts) (green dots in 11.). Remove the coil packs by pulling them straight out at the angle they are installed at. They have a clip to hold them on the spark plug tops and might require a bit of pressure to get them to come out (12.). I recommend keeping them in the order they are removed. Put the oil cap back in place to keep debris from getting in the engine.

|

11.

12.

|

|

7. Remove the 4 intake hoses (8 x 8 mm hose clamps). I have some caps to go over the exposed intercooler intake piping. They are 2" PVC pipe caps w/ a loop of foam on the inside (13.). They slide right over the ends of the pipes to keep any and all debris and bolts from going into the pipes (14. & 15.). Stillen's intercoolers come with some perfectly sized red caps that can be used the same way. If anything plug the openings with rags, but remember to remove/check they are removed before putting the hoses back on.

|

13.

14.

15.

|

|

8. Disconnect the injector connectors (blue dots in 16.) and the fuel rail temp. sensor (green dot in 16.). For the injector connectors, I use a pair of dental picks to pry the wire clips outwards and then carefully pull the connector up. By now, unless it's a low mileage 90-94 or a 95+ the connectors will be extremely brittle. Expect them to break, hopefully it won't ruin the connector. The injector connectors changed in 95 to a more heat resistant design. For these, simply squeeze the clip and pull them off.

9. Disconnect the grounds on both sides of the rear of the plenum (2 x 10 mm bolts) (white dots in 16.). Disconnect the detonation sensor plug (red dot in 16.), dead center pointing upwards on a bracket on the rear of the plenum. Disconnect the O2 sensor (yellow dot in 16.) and variable valve timing connector (orange dot in 16.) just to the driver side of the detonation sensor connector on brackets. The last three are the worst, they have the injector style connectors (all years). The idle air adjusting unit has two and the idle air regulator has one. They are bolted to the backside of the plenum on the driver side. Take your time and try not to destroy the connectors on them. The idle air adjusting unit has a light blue and a yellow connector on it (blue and yellow dots in 17. respectively). The blue one is sideways and the yellow one points upwards. The connector on the idle air adjusting unit is light blue and oriented the same as the other blue connector, it's further towards the center of the engine on the back of the plenum. Disconnect both throttle position sensor connectors (green dots in 18.). Disconnect the safety boost cut solenoid plugs on each side. They are the square black connectors midway along the sides of the engine, or still clipped to the hard pipe coming up from each turbo.

10. Remove the idle air tube running the length of the driver side of the plenum. Pull the clamps back at the front on the curved hose and on the rear where it goes into the idle air adjusting unit on the back corner of the plenum. The tubing might have the wiring harness clipped to it. Disconnect the harness and remove the tubing.

11. Disconnect the two small hoses from under the fronts of the throttle bodies.

|

16.

17.

18.

|

|

|

|

|

12. On the driver side, disconnect both hoses coming downward from the throttle body area. One goes straight down (yellow dot in 19.), the other comes out at an angle (green dot in 19.). PB Blaster works great here. Remove the dipstick (blue dot in 20.). Disconnect the two large vacuum lines going to the brake booster and the clutch booster (TT only) (2 x clamps) (white dots in 20.), flip them back out of the way, or totally remove them (2 x clamps). Disconnect the hose going from the clutch booster vacuum fitting tree towards the front of the car (1 x clamp) (green dot in 20.). Disconnect the small hose that is coupled with the small hose from the upper fuel rail off the brake booster fitting tree (yellow dot in 20.). Remove both fitting trees from the plenum (orange dots in 20.). Pull the clamp back on the PCV valve's hose so it can come off the valve when the plenum comes out.

|

19.

20.

|

|

13. Remove both turbo outlet pipes. Loosen up the hose clamps on the top of the rubber coupling on the turbo (2 x 8 mm hose clamps). Remove the two bolts holding the pipes onto the plenum (2 x 10 mm) (blue dot in 21.). Remove the entire assemblies. Plug the turbo outlets with rags to keep debris out of them. The wastegate solenoid connectors might be clipped onto the hard pipe part of the assembly. On the driver side, there is a bracket coming down from the plenum toward a bracket on another piece of tubing, disconnect it (1 x 10 mm). It used to have one of the hoses disconnected in the last step attached to it (green dot in 19.). Use a stubby 10mm wrench to disconnect the EGR return tubes on either side of the plenum (green dots in 21.).

|

21.

|

|

14. Remove the side bracket bolts (4 x 12 mm bolts) (orange dots in 19.). Remove the tubing on passenger side of the plenum. Disconnect the EGR feed tubes from the bottom of the plenum (4 x 10 mm bolts) (green dots in 19.). A 10 mm stubby wrench will get things started, and a 1/4" drive socket on a short extension will get the bolts removed quickly.

15. On the passenger side, disconnect the hose coming from the back corner of the plenum and going down to the turbo (1 x clamp). Disconnect the small EGR vacuum hose on the side of the plenum near the last hose disconnected. There is a same size hose coming out of the back side of the plenum on the corner, disconnect it. PB Blaster works great here as well. Pull the clamp back on the PCV valve's hose so it can come off the valve when the plenum comes out.

|

|

|

16. Remove the plenum from the lower intake by removing the bolts on the top center (8 x 12 mm bolts) (22.). The short bolt is the front passenger side (red dot in 22.), the odd bolt with the threaded hole in the top is second from the rear on the passenger side (orange dot in 22.). Carefully pull the plenum upward and forward. There are still two hoses connected to the rear of the plenum in the middle (23.). Disconnect these and remove the plenum entirely (2 x clamps). Immediately cover the lower intake openings so no debris falls into the intake (24.).

|

22.

23.

24.

|

|

17. Remove the caps on the injectors. I recommend using a manual impact driver with the correct size phillips bit on it to remove the screws (12 x phillips screws). If the screw top gets stripped, they are incredibly difficult to remove (25. & 26.). Be careful not to loose the rubber insulators (red dot in 26.) and metal shims (yellow dot in 26.) on top of each injector .

|

25.

26.

|

|

18. Remove the bracket on the rear of the lower intake (1 x 10 mm bolt) (27.), it has the ground strap going onto it from the lower fuel rail. Remove the fuel rail with the injectors (6 x 10 mm bolts) (28.), don't loose the small black plastic insulators on the fuel rail.

19. Soak the injector seals with lots of PB Blaster. Set it aside for now if continuing on with some of the other jobs.

|

27.

28.

|

|

Other tasks:

Removing the valve covers to paint or replace seals. Also covers all the PCV hoses to be replaced

20. Remove the PCV hose from the fitting on the driver side exhaust valve cover (1 x clamp). Remove the PCV hose coming from the rear of the driver side exhaust valve cover (2 x clamp). Remove the PCV hose from the tube on the rear corner of the passenger side of the engine (1 x clamp). Disconnect the PCV breather hoses from the fittings on the front of each intake valve cover (2 x clamps) (29.).

|

29.

|

|

21. Remove the plastic spark plug hole covers (8 x 12 mm bolts) (red dots in 30.). Be careful not to lose the rubber seals at the ends of the tubes. Remove the intake valve covers (16 x phillips screws) (yellow dot in 30.). Cover the cam and valve assemblies to keep debris from getting on them. Removing the exhaust cam covers (blue dot in 30.) (16 x 10 mm bolts) is a little more difficult. On the driver side, the PCV hose on the rear has to be disconnected and be careful with the dipstick bracket. The side brackets holding the plenum to the block might have to be removed (4 x 12 mm bolts) to get to the bolt behind them. The use of a 1/4" drive 10mm socket on a u-joint will help to remove the bolts. Cover those cam assemblies as well once the valve cover is removed.

22. I took the opportunity to paint the intake valve covers on this car. High temp Duplicolor 1608 red looked good to the owner. Peel out the rubber gasket, remove the rubber screw insulators, use a chemical paint stripper (using all cautionary methods: safety glasses, chemical resistant gloves, etc.) to remove the paint from the outside. Use degreaser to clean the inside if necessary. Be careful not to break the plastic breather openings on the underside of the cover. Repaint the covers as desired. The exhaust covers should be about the same. Remove the gaskets (carefully scrape clean the mating surfaces if required, do not scratch any of the mating surfaces, so leaks my result), clean the covers up and paint them. Clean the screws, bolts and insulators.

|

30.

|

|

23. Reconnect the rear PCV hose with the clamps in the middle. Note the orientation of the hose as it is 'sloped' to one side. Position it where the small end is angled toward the block. Put the gasket or sealant on the covers and reinstall them (16 x insulators, 16 x phillips screws, 16 x 10 mm bolts). I used some Permatex RTV to seal up possible leak points in the covers (31.). The exhaust covers are difficult to get back on without getting sealant all over the place and potentially compromising the seal. Be careful to put the dipstick bracket on top of the exhaust valve cover flange and not under it. Tighten all four covers in a crisscross pattern. Torque the exhaust valve cover bolts to 4.6-6.1 ft-lbs. Torque the intake valve cover screws to 0.7-2.2 ft-lbs. (32.).

24. Reconnect the rear PCV hose and side the clamps back in place (2 x clamps). Pay attention to the orientation of the clamps, they should 'point' to the rear. Reconnect each of the side PCV hoses Disconnect the PCV breather hoses from the fittings on the front of each intake valve cover (2 x clamps), point the clamps outwards. Reconnect the PCV breather hoses on the fronts of the intake valve covers (2 x clamps). If the tubing was removed to repaint the covers, use a plastic mallet to pound them back into place. Install the plastic spark plug hole covers (8 x 12 mm bolts). Be careful not to lose the rubber seals at the ends of the tubes. No torque spec is listed.

|

31.

32.

|

|

Bypassing the throttle body water jackets

25. Use the 1/4" heater hose to bypass the throttle body water jackets. Attach it to the rear tube on the passenger side and swing it around the corner to the water pipe coming up off the turbo (33.). Cut it to proper length and clamp it down (2 x clamps). Do the same thing on the driver side (2 x clamps) (34.-36.). Picture 34. shows the second hose not pictured back in 23.. NAs will be configured slightly differently.

|

33.

34.

35.

36.

|

|

Removing the safety boost cut solenoids if an EVC is installed.

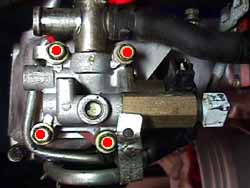

26. Remove both safety boost cut solenoids (4 x 8 mm bolts) (37.). Pull them straight up and the hoses will come off the intake tubing. They should already be disconnected from the wastegates if the EVC is installed. Cap off the nipples on each intake pipe with 5/32" rubber caps. Use zip ties to secure the nipples. This part of the intake tract is always under vacuum, never boost (38.) but a boost pressure check would blow them off.

|

37.

38.

|

|

Cleaning up the plenum (or trading for a polished one)

27. Disconnect any hoses going to the throttle bodies (39. & 40.). Remove all the hoses and tubes from the underside of the plenum (4 x 10 mm bolts and a lot of hose clamps) (41.). Remove the idle air adjusting unit (4 x 8 mm long bolts) (42.) and the idle air regulator from the rear of the plenum (2 x 8 mm short bolts) (43.). Remove the throttle bodies and mid linkage (7 x 6 mm hex head bolts) (mid linkage in 44.) from the plenum. Note how the throttle bodies fit to the mid linkage. Remove the plug from the passenger rear corner of the plenum on the top (1 x 14 mm bolt) (45.).

28. Clean the throttle body and plenum gasket mating surfaces. If a different plenum is going onto the car, check every single hole on it for proper threads, etc. Finding ruined threads on the EGR bolt holes on the bottom of the plenum later is not fun to deal with. If holes need to be tapped out, make sure ALL the metal shavings are out of the plenum. Cleaning the plenum with degreaser and water is OK, just make sure to dry off the outside so it doesn't get water spots on it. If using some non-petroleum cleaner, make sure it's aluminum alloy friendly.

29. Attach the mid linkage on the new plenum (3 x 6 mm hex head bolts, the short one goes on the bottom). Torque in 3 steps: finger tight, 3.6 ft-lbs, 14 ft-lbs. Put some grease in the sockets on the ends of the linkages. Slip the throttle body linkages into the mid linkage fittings. Attach the throttle bodies to the plenum using fresh gaskets (8 x 6 mm hex head bolts). Torque in 2 steps: 6.5-8.0 ft-lbs, 13-16 ft-lbs.

30. If the throttle body water jackets are not being bypassed, attach the tubing with new hoses on the underside of the plenum (4 x 10 mm bolts and a lot of hose clamps). I won't go into detail, but here for TT or here for NA are all the parts. I'd replace every rubber hose under there. Otherwise this has all been eliminated in step 25 above.

31. The only downside I could find to leaving off all the tubing on the bottom is there are two clips for the driver side O2 sensor and VTC solenoid connectors on it where it goes around the idle air adjusting unit and the idle air regulator. I opted to remove all of it. Not only does it bypass the throttle body water jackets, but it also bypasses a vacuum hose going to the EGR valve and one going to the carbon canister in the front of the car.

32. Clean the idle air adjusting unit gasket mating surface. Attach the idle air adjusting unit to the plenum with a new gasket (4 x 8 mm long bolts) and the idle air regulator. Torque all to 6.2-8 ft-lbs. Attach the new hose between the idle air adjusting unit and the idle air regulator (2 x hose clamps). Replace the plug from the passenger rear corner of the plenum on the top (1 x 14 mm bolt). Torque to 12-14 ft-lbs. Snug in the PCV valves, there should be a little bit of thread exposed even when they are seated. There is no torque spec listed for them (2 x 19 mm valves).

|

39.

40.

41.

42.

43.

44.

45.

|

|

Replacing the injectors

33. If the injectors haven't been soaking in PB Blaster, soak them now and wait. It is incredible how easy this is after a PB Blaster bath. Split the rail in half by removing the fuel hose holding the halves together (2 x phillips hose clamps). I made a tool to extract the injectors from the rail using an 11mm Craftsman socket to cover the pintle end of the injector (bottom) and a cut up PVC pipe fitting on the electrical connector side. Simply put the socket over the pintle and the PVC tool on the top over the injector, but on the mounting ears. Tighten the vice a turn or two and the injector will pop right out of it's swollen seals (46.). Repeat for all 6 injectors.

|

46.

|

|

34. Clean up the rail and prep it for the new injectors. Leave the protective plastic covers on the pintle ends. Put both new rubber O rings on each injector, using some motor oil to lubricate them. They should be able to be installed by just pushing/twisting them in place. If that proves too difficult, use a 24mm 12pt 1/2" drive Craftsman socket on the fuel rail, and I used a crescent wrench on the connector end in the vice to reverse the removal technique (47.). If using the longer hex head screws, it might be possible to pull the injectors into place by putting the caps with the upper insulator in place. Start each screw and tighten a little bit each until the cap is tight against the rail. Make sure the O rings go in smoothly and don't get pinched, make sure the top of the injector does not get squashed in and also make sure the connectors are squared up and facing outward. They can be twisted slightly afterwards, but I would not push my luck. If anything doesn't feel right, stop now, back up and fix it. It is frustrating to do all this work and then have to backtrack all the way back in to replace s cheap O ring if it gets pinched (48.). I know from experience.

35. Cut a matching length of high pressure fuel hose to reconnect the rail halves to each other. Loosely clamp them together with the clamp screw heads facing forwards, not up. Remove any of the old injector seals in the lower intake that didn't come out with the injectors. Carefully clean the seal seats and oil up the new injector seals, placing them in the lower intake the same way the old ones were in there (they have a bevel and I forgot to note which way they fit). Remove the protective covers on the injector pintles.

|

47.

48.

|

|

36. Use 12 M5 x 16 mm with .80mm pitch hex head socket screws with a lock washer and a washer on each of them on the injector caps (49.). Place the small metal half washer on top of each one, followed by the rubber insulator, and finally the cap. Note the flat orientation with the edge of the cap. Torque the hex head screws to 1.8 - 2.4 ft-lbs (50.). Reattach the ground strap and the detonation sensor connector bracket to the back of the lower intake with the tab pointing backwards. Tighten the clamps on the front of the fuel rail. With them pointing forwards, they can be tightened later if they loosen up for any reason with out having to tear down the top of the engine to get to them.

37. Gently set the fuel rail back into the seals on the lower intake. Make certain everything is fitting as it should. Again, a pinched seal at this point is a pain to come back and fix afterwards. Take some extra time examining things now to avoid re-doing this part. Make sure the black plastic insulators are on the fuel rail (12 pcs.). Bolt the fuel rail back to the lower intake (6 x 10 mm bolts). No torque spec is listed in the service manual.

38. If upgrading the injectors to a higher flow rate, don't forget they need a different ECU chip installed to handle the different pulse width for correct fuel flow. See the ECU chip swap TECH page.

|

49.

50.

|

|

Installing the plenum

The steps are basically the reverse order, these are added notes:

39. If all the hoses were pulled from the underside of the plenum, the EGR hose will need to be extended and joined on the passenger side. Use the 3/16" hose and barb to extend the hose. Cut to proper length. The carbon canister hose on the driver side that was on the underside tubing will now need to be extended and joined on the balance tube when it's reinstalled. Use the 1/4" hose and barb to extend the hose. Cut to proper length.

40. Remove the rags from the lower intake. Set the new plenum to lower intake gasket on the lower intake. The side with the factory sealant goes downward. Set the plenum carefully down on the gasket. If the throttle body water jackets were not bypassed, reconnect the two hoses at the very rear of the plenum first (23. & 34.). Make sure nothing is keeping the plenum from seating properly on the lower intake. It's too easy to get the detonation sensor wire or something else trapped in there, causing a huge vacuum leak. Seat the EGR tubes into the bottom of the plenum. If the throttle body hoses were bypassed, make certain the hose coming from the front driver side to the rear moves easily under the plenum and isn't pinched anywhere. Pinching this line will kill a turbo in short order.

41. Torque the plenum bolts (8 x 12 mm bolts) to 12 - 15 ft-lbs. in a crisscross pattern.

42. The EGR tube bolts (4 x 10 mm bolts) are torqued to 6.2 to 8 ft - lbs.

43. There is no torque spec listed for the side braces on the plenum, or the fuel rail. Use good judgment and remember this is a soft aluminum alloy, it will strip out holes easily. I'd think 6 - 8 ft-lbs is max torque.

44. Replace all fuel hose couplings with new high pressure fuel hose (fuel injector rated). It's a good time to replace the fuel pressure damper and fuel pressure regulator if the car has some miles on it.

45. The balance tube nuts and bolts (3 x 12 mm acorn nuts, 2 x 12 mm bolts) are torqued to 12 - 15 ft-lbs.

46. I opted to leave the metal wire tree on the passenger side of the plenum off. I just looped the wires back on themselves and away from the turbos and exhaust. If the underside tubing was removed, the O2 sensor and VTC connectors won't have clips to mount on. They rest easily on the back of the plenum.

47. Do not forget to remove the rags in the turbo outlets and the front intake hoses before starting the engine.

Originally published: 11/14/2004

Dallas DamonZ

Back to TECH |

|