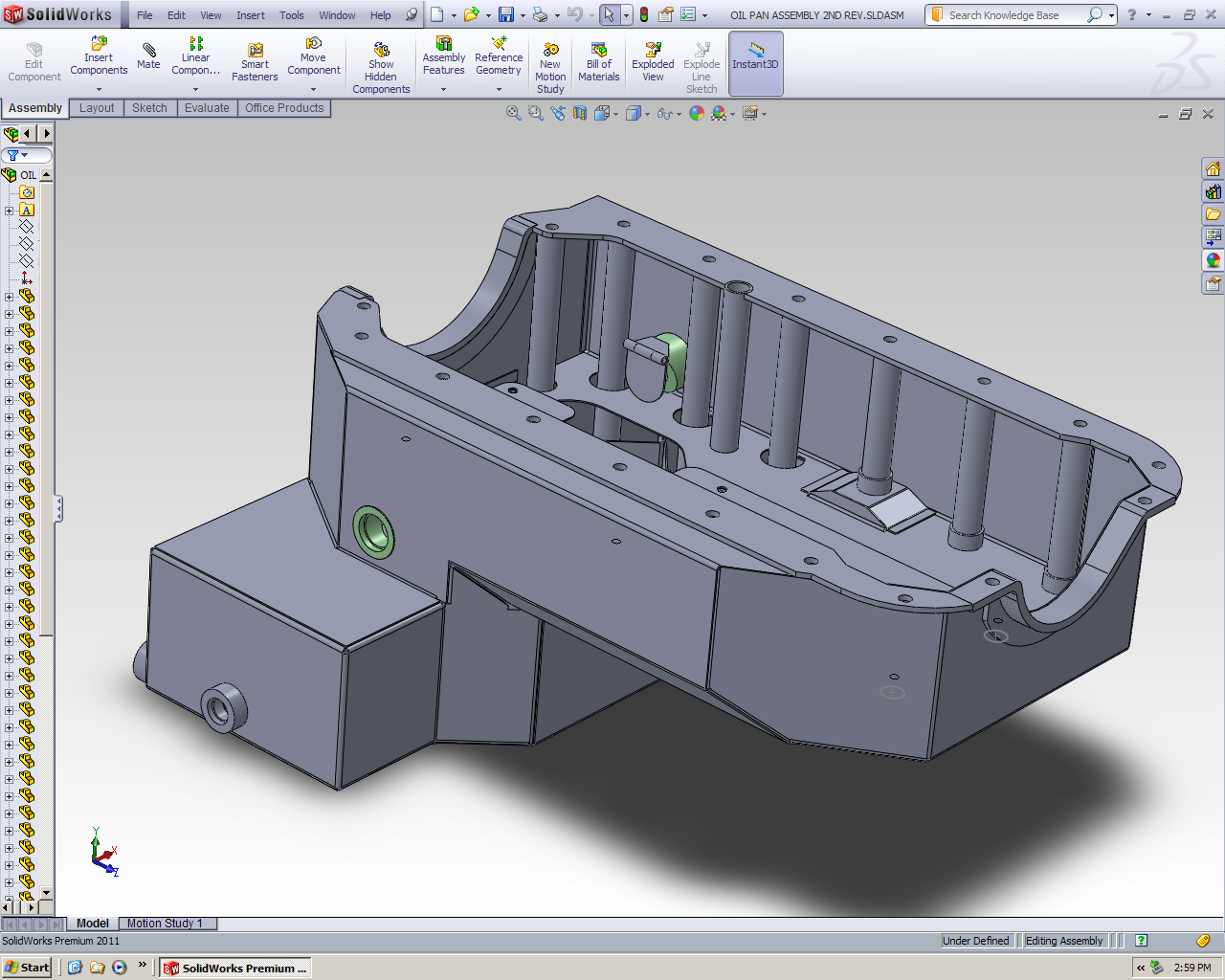

| I'm working on a prototype steel oil pan for a stock VG block/girdle in a Z32 chassis and am finally at a point where I can show some pictures and design details. Enjoy. 100% designed and pre-assembled in SolidWorks, final render

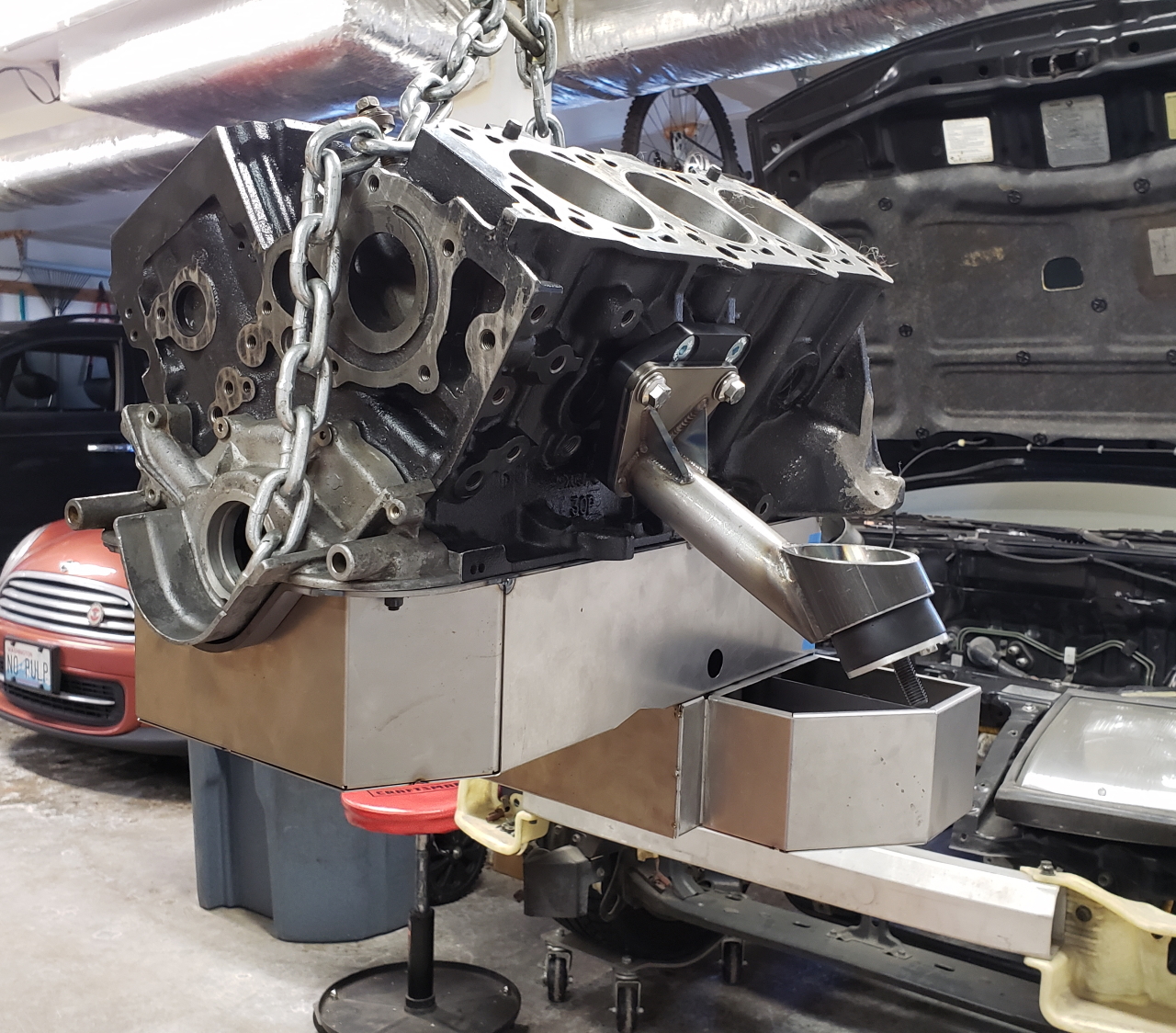

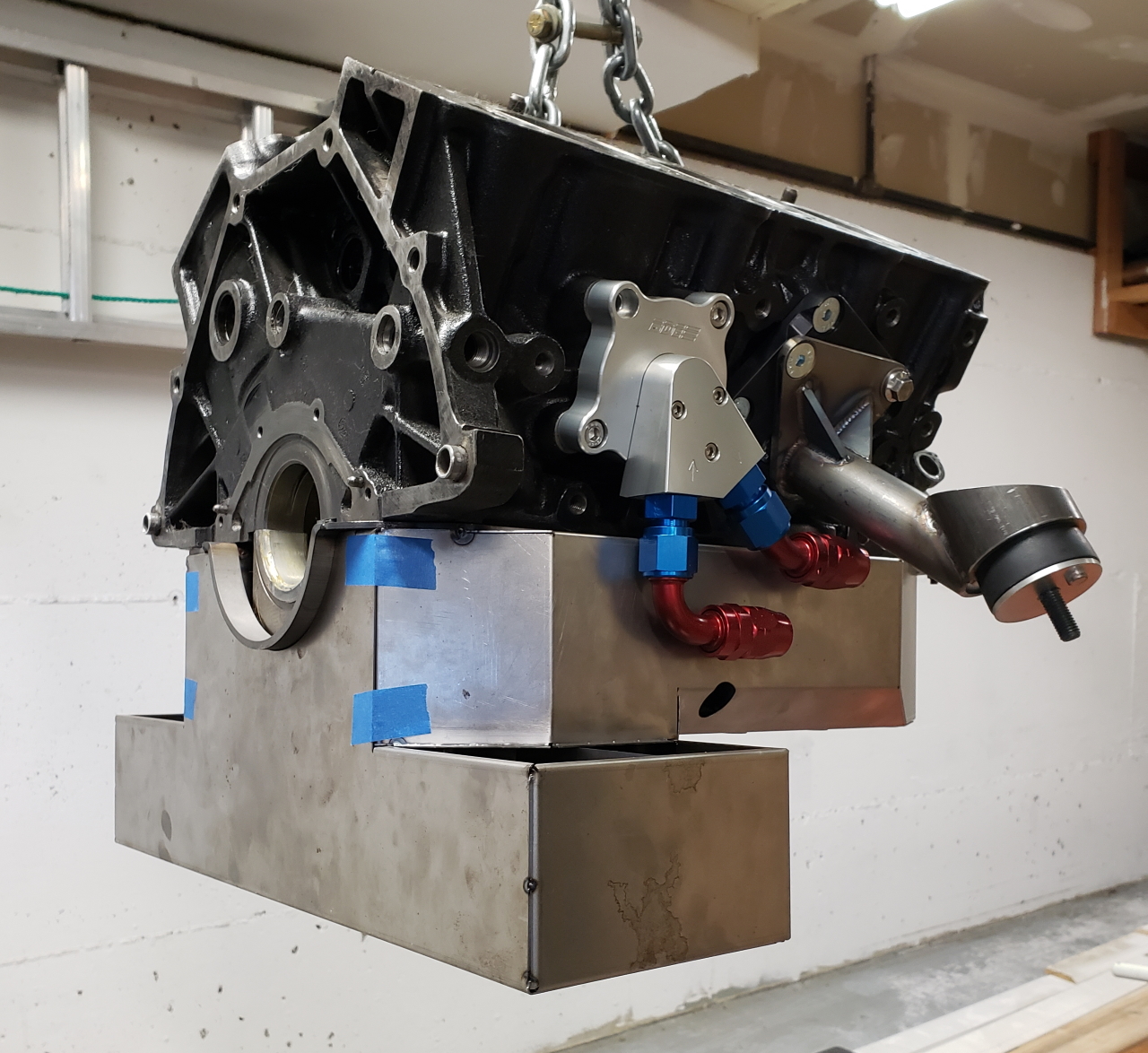

Prototype pics, some things will change in the final version from what you see here.

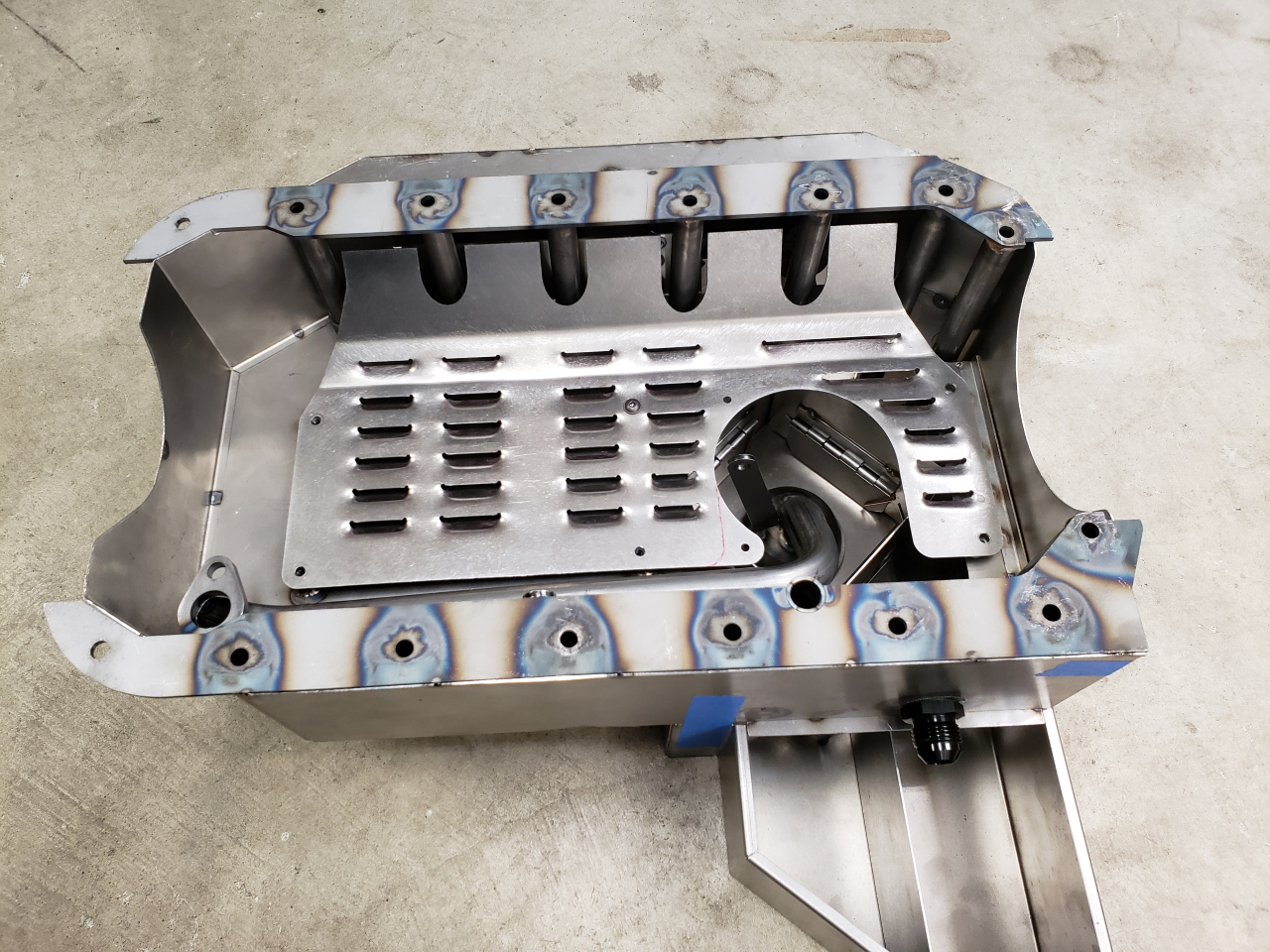

Right side - all of the tubes are for external bolt access holes to allow moving the sides out to maximize pan volume and make room for as much oil control as possible.

Left side

Bottom - bolt access tubes are visible here. I had to make a magnetic 12 point socket to hold the nuts for easy assembly.

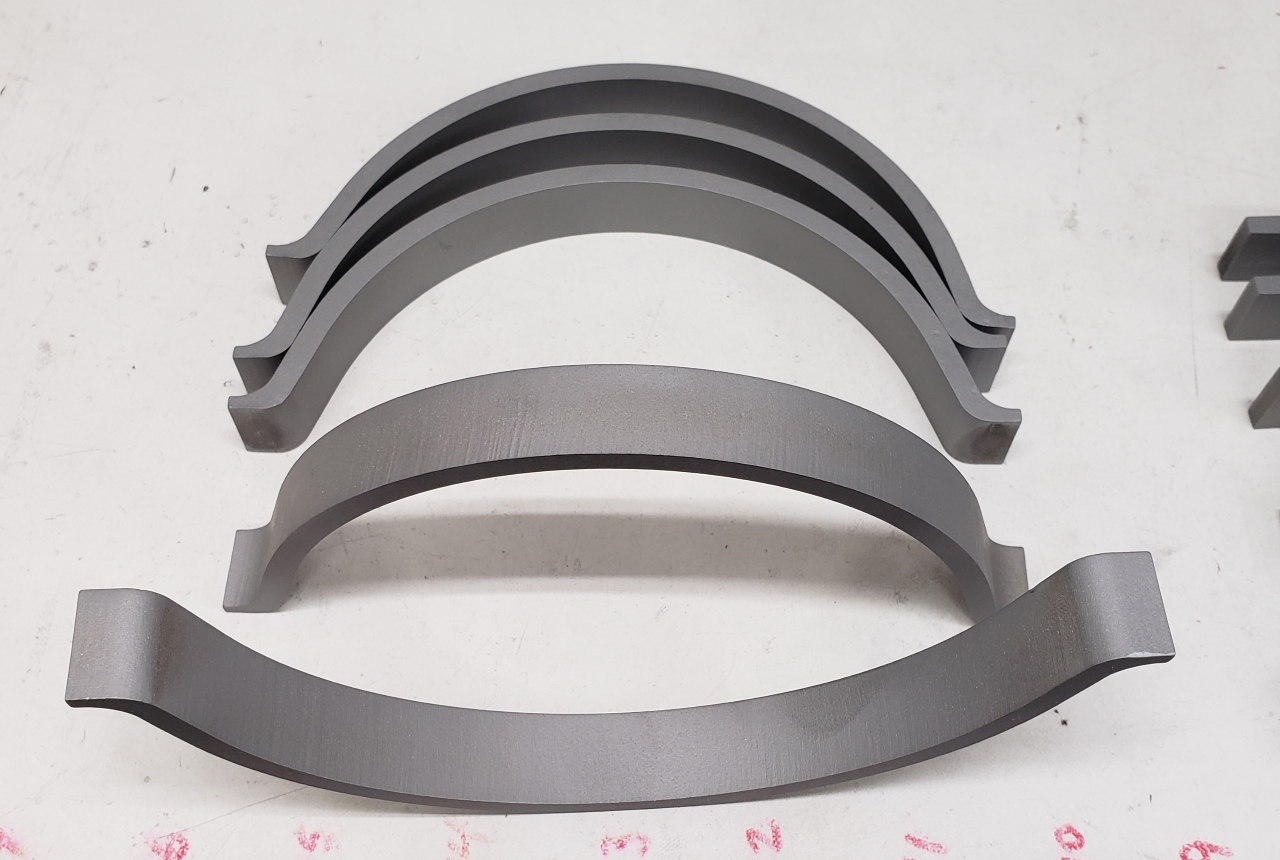

Sump baffles with trap doors - basically 4 mini-sumps all feeding into the center where the pickup resides.

Fit testing to block and chassis

Oil filter tree? We don't need no stinking oil filter tree...

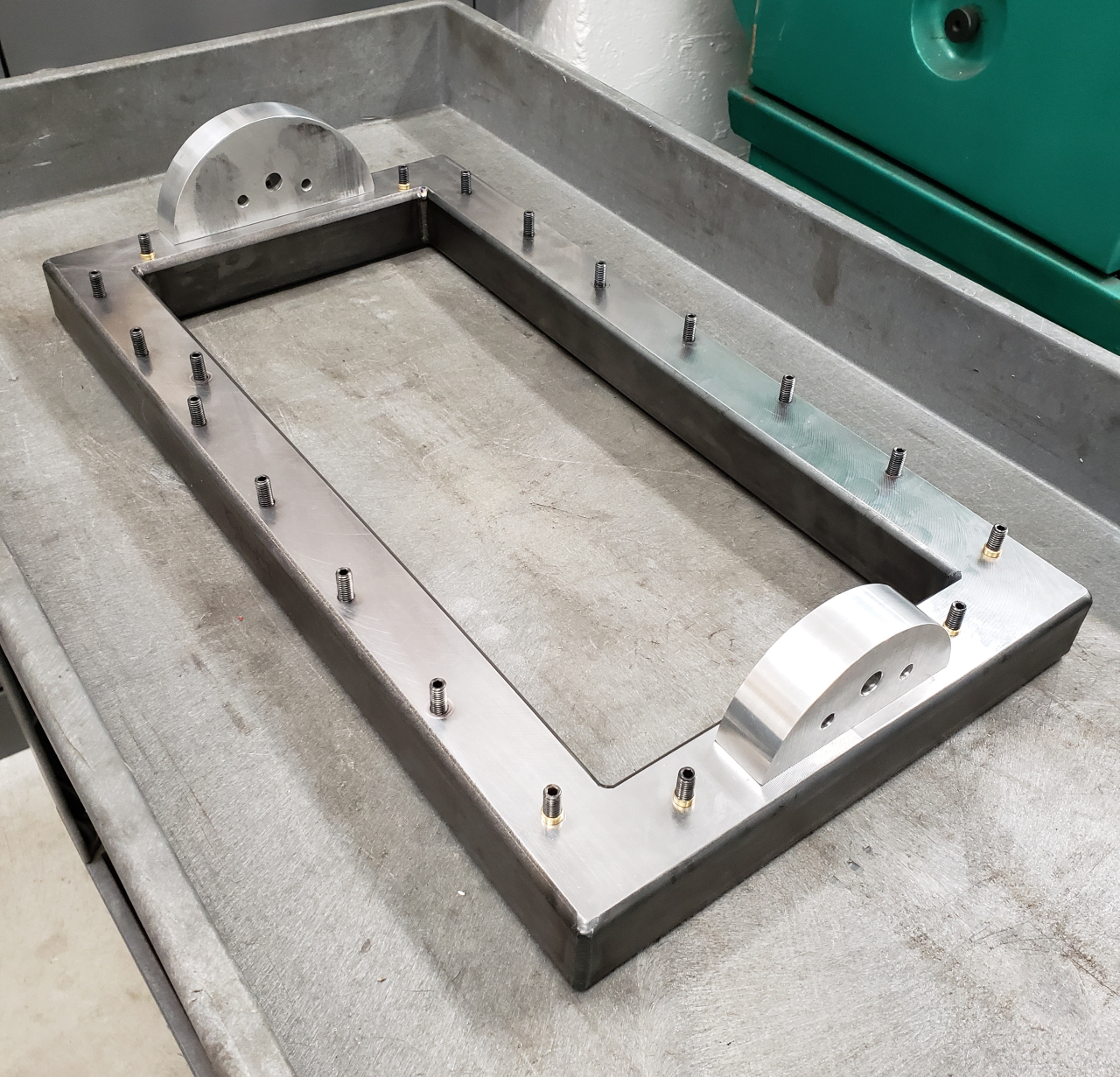

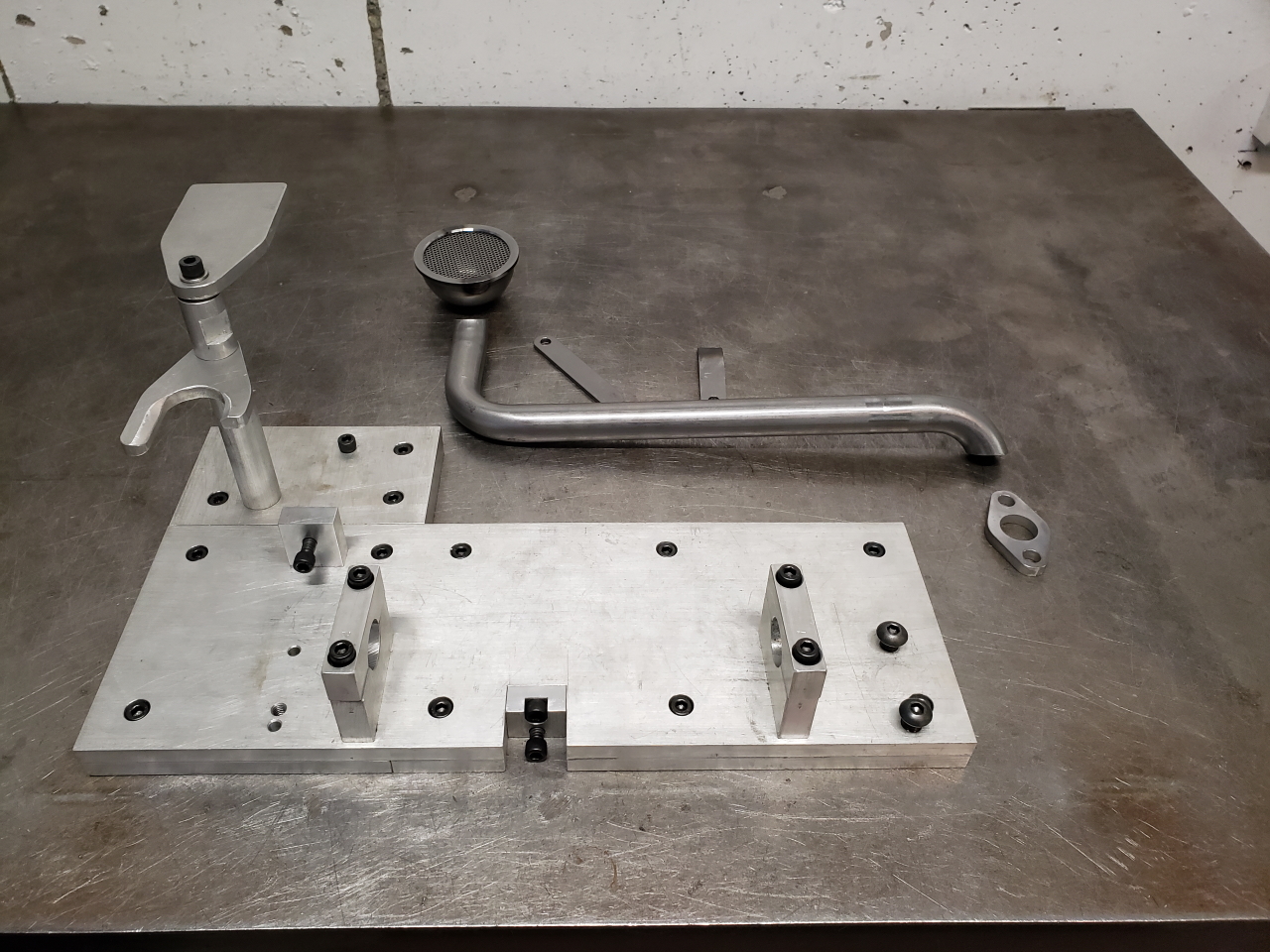

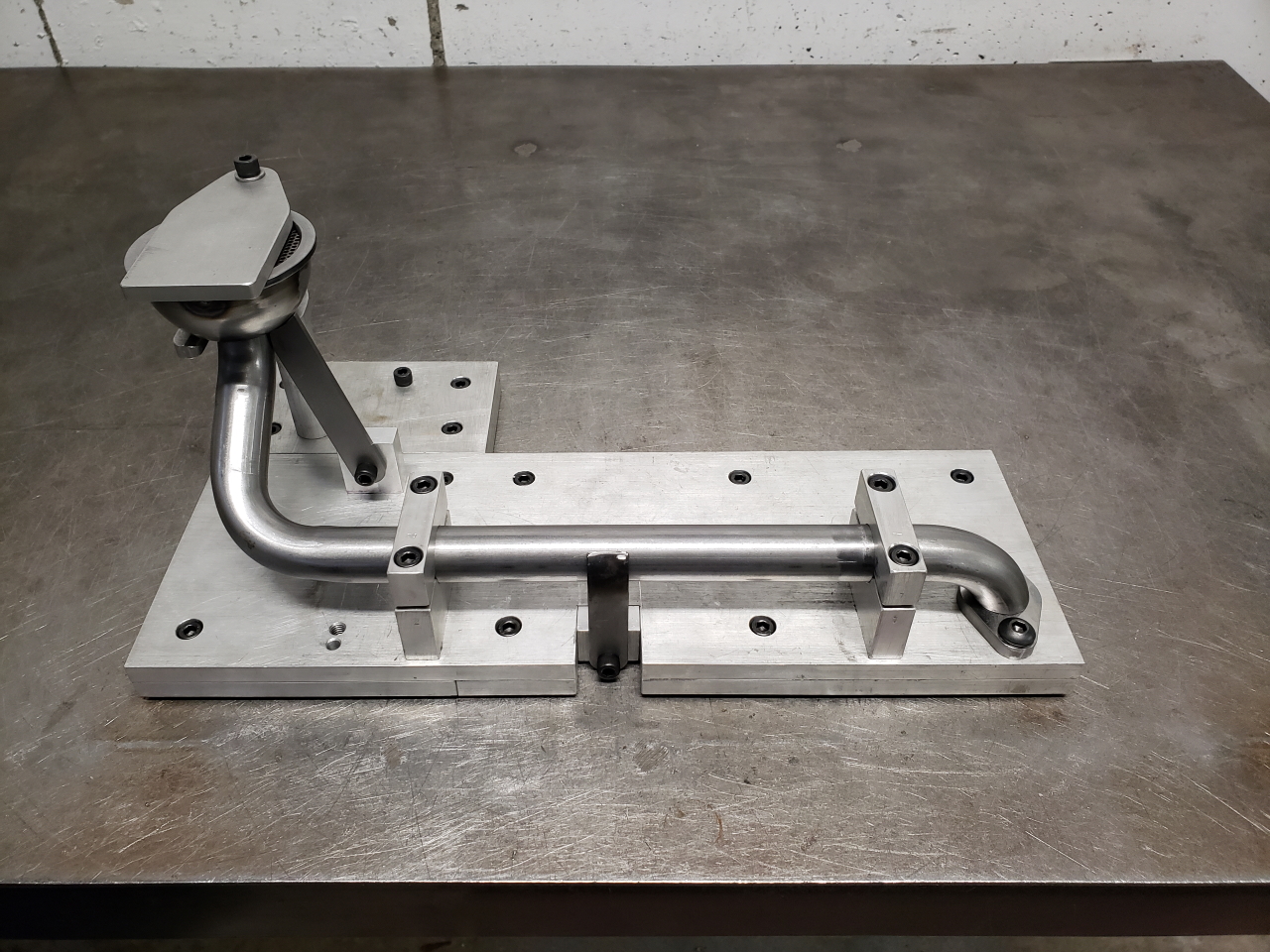

Assembly/weld jig to align the gasket rails and keep them all as straight as possible while welding.

Gasket rails and bolt access tubes attached.

Water jet cut ends - cost $70 each at this stage but still way less than machining them regardless of quantity.

Oil pump pickup assembly jig and parts

Louvered windage tray removes oil from the rotating assembly and shields it from the internal oil/air tornado spinning around the crank so it can return to the sump faster.

Turbo oil drain baffle - the boss has an angle cut on the sump side so the little trap door will take at least 0.5 G in a corner for it to swing closed and prevent sump oil from climbing into the drain tube on hard cornering. Also works as a shield to prevent windage oil from finding its way in during straight line acceleration.

-10 AN ORB on the other side of the turbo oil drain bosses... pretty little welds :) The rest of the seams will all be TIG brazed with silicon bronze to keep the heat input down and reduce warpage.

Hopefully this all shows "some" of the work and investment that goes into developing a part like this prior to seeing a penny of profit... as it should be.

|