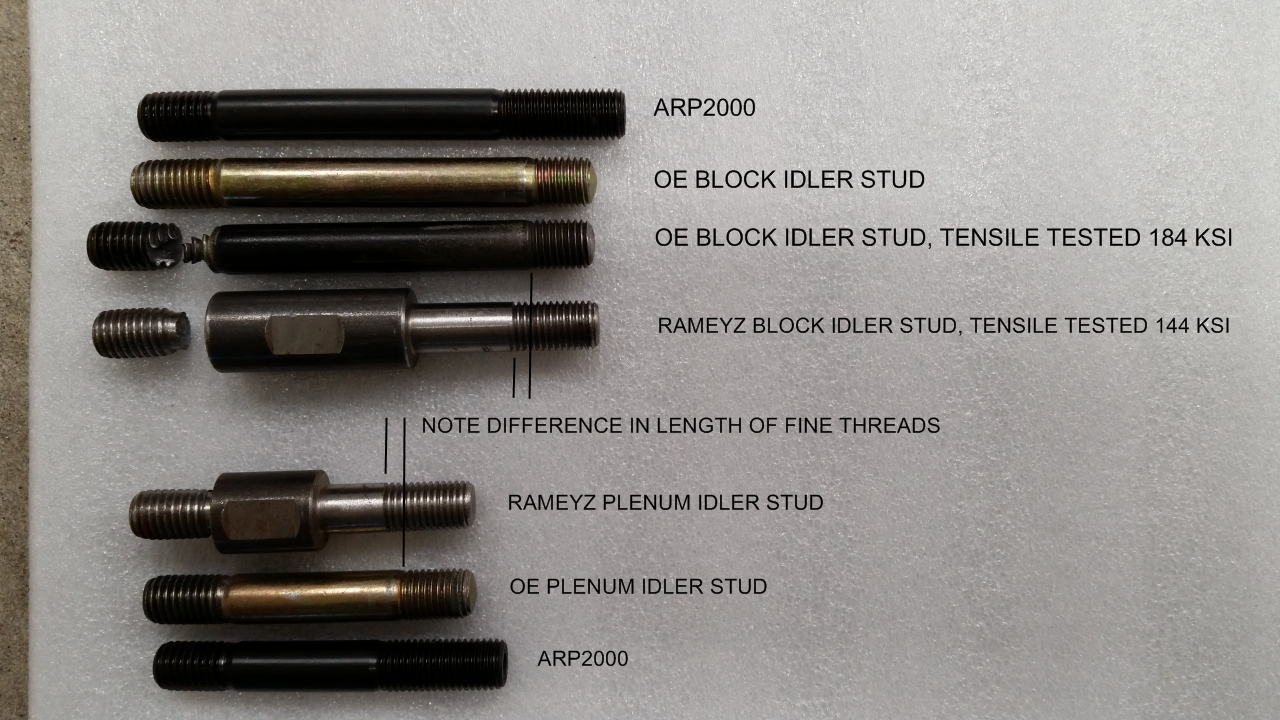

| I've never quite agreed with the need for upgraded idler studs but I also didn't want to poo poo on someone's idea that seemed to be filling a demand. Since the RameyZ idler studs went out of production, CZP asked me to look into making a BDE version... I'm certainly not interested in copying anything or in making something unless I can truly offer an improvement over the OE part(s) so I decided the best way to approach this was with a direct comparison and let the cards fall where they may. Apparently there was an epidemic of broken OE idler studs at some time which launched the whole upgraded idler stud offerings that we see now. I've yet to see one break, so I can't really speak to the series of events that makes this happen, but I think I can offer an opinion. Let's start by tensile testing some studs. I found the OE stud has a Yield Tensile Strength (YTS) of 164ksi and an Ultimate Tensile Strength (UTS) of 184ksi. Next I tested a RameyZ stud and found its YTS was 135ksi and UTS was 144ksi. Lower than the OE properties, but I will admit much higher that what I thought it was going to be. Second, let's compare measurements. Besides the obvious large diameter shoulder on the RameyZ studs, one other major difference is the amount of fine threads. RameyZ studs are threaded about 3 more threads deeper than the OE studs. The OE plenum stud has an unthreaded section that is 1.340" and the OE block stud's unthreaded section is 2.360" while both RameyZ studs unthreaded sections are 0.150" less. After noticing this, I decided to measure the length of the idlers themselves. The plenum idler is 1.345" and the block idler is 2.370"! That's damn near the same length as their stud's unthreaded sections! And what that means is if the installer A)doesn't install the stud(s) fully into the plenum/block or B)doesn't use a washer under the nut, the nut will bottom on the stud threads and it will be almost impossible to properly preload the stud while torquing the nut. And if that happens, it should be no surprise to anyone that the stud would eventually break from fatigue. Conclusion

The RameyZ shoulders, which help indicate being fully installed, and their additional fine threads combine to foolproof the assemblies to the point that even a reduction of material strength does not weaken the assembly enough to allow it to fail. However, they should not be torqued to the factory specs because of their lower tensile properties and the potential to exceed its YTS. Since the RameyZ studs are no longer available, if you want to economically upgrade your studs, ARP has some that will work made from ARP2000 material (YTS 200ksi, UTS 220ksi). They do have a shorter unthreaded section to foolproof the assembly. Please note in the picture below that the ARP2000 studs are longer than OE but I did mock-up an engine with timing covers and they both clear without any issues. Because this is a product I can't possibly improve upon, you won't see a BDE version but you should be able to get the ARP studs from Concept Z Performance in the near future. Of course, you could always just use the OE studs and simply pay attention while installing them.

|