| NOTE: if you aren't patient just stop now. This took well over two hours, is very tedious, and it did occur to me to spend $300+ at china Freight for an English Wheel, but the opposing wheel might have damaged the paint whereas this method does not. Also, this is not a cure-all for any dent on any part of the sheet-metal. A dent too close to a factory bend or seam will be in-accessible. The results are not perfect! But the fender is a lot better than it was, and I dare say it would take quite a polished condition with plenty of sunlight to see the leftover imperfections. Not to get into a rant, but basically my ex-girlfriend's new boyfriend backed into my Z in a parking lot. My motion-detector set the alarm off and he took off before he did any worse and before I ran out to the car. Long story short, he found out I was looking for him and a couple weeks later he left town and hasn't been back, and he took the psycho-bitch with him. I'm still hoping to run into him somehow and give him "my best." ;-)

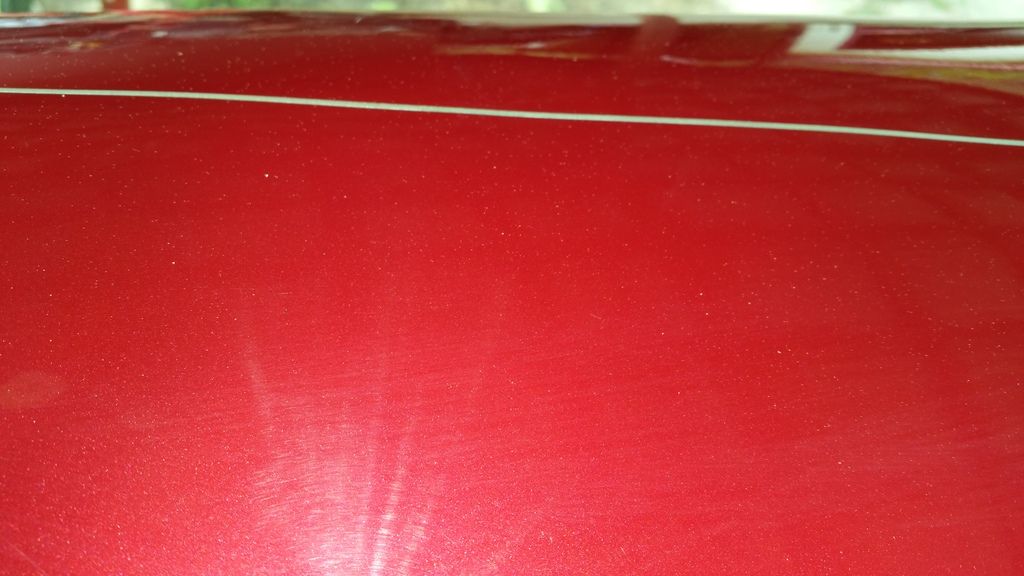

So I was left with a few creases in my driver's front fender above and rear of the wheel well:

There is one crease in particular that was vertical to the horizontal line along the silver pinstripe and was the worst one:

Now, everyone knows I'm kinda special, borderline retarded, and I'll be the first one to say (and actually have in a recent post) that I'm not artistic and I can uglify stuff without even trying. But I had an idea (uh-oh, lol).

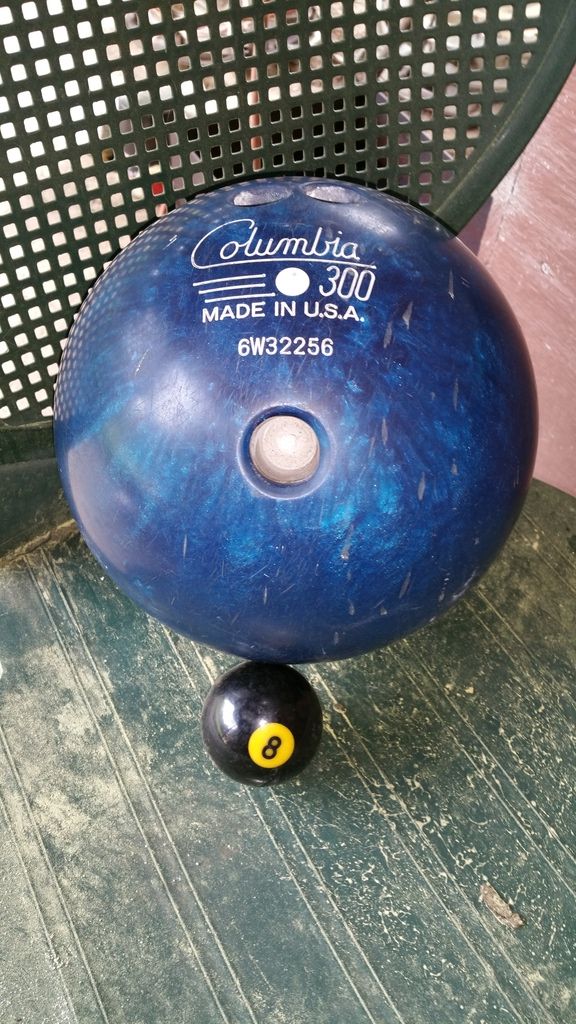

If I could get something heavy and round I could roll it back and forth on the dents from the inside of the fender and smooth everything back out; no banging on anything, no drilling, no welding, no pulling. Just GENTLE back and forth.........what's heavy and round?

Had this stuff laying around; never use them anymore. A long time ago I was going to tap the 8-ball and make it into a gear-shift knob on my old 280Z. I thought maybe the 8-ball would be useful for a small spot or to finish a dent out or get closer to a factory bend or seam. Now all I needed was a flexible surface that would receive the outside of the fender and allow the pushing from the inside by the bowling ball/8-ball so that the dents could relax and straighten to the rest of the surface of the fender. How about a huge bag of sand? DRY sand. I got four bags of cheap sand from Lowes, about $3.50 each. Clay will not work, an 80lbs bag of horse feed will not work, a bag of marbles will not work. The material inside the bag must be something fine and flexible. Maybe an 80lbs bag of corn meal....maybe. Even a bag filled with bird-seed I think would be too coarse. The sheet-metal is thin and easily deformed. The bag must be huge! Seriously, even the 45 gallon garbage bag I used was not big enough. You want to be able to lay the entire fender across the bag. I wound up having to support the forward end of the fender with some blocks and used the plastic bags that the sand came in to buffer the fender from the blocks and protect the paint. You need to pick a smooth, hard, flat surface where you're going to do the work (like my concrete slab/pad), make sure it's clean so as to avoid ripping the bag and then put the bag there and fill it with the sand because trying to move the bag with all that sand in it will just rip the bag and then you get to start all over.

Flatten out the sand in the bag with your hands as best you can. It doesn't have to be perfect cuz the fender will make it's own shape in the bag/sand.

Make sure the entire fender is supported one way or another.

Be sure to protect the fender/paint that isn't on the bag/sand from whatever you support it with such as with the plastic bags from the sand as I did. A fender-cover or blanket would have been even better, I'm sure.

Look at the dents on the outside and make an excellent approximation where they show up on the inside. It won't be as easy to see on the inside because the inside is probably going to be really filthy and isn't shiney like the painted outside. Gently place the bowling ball in the fender and roll it back and forth over the dented area just a few times. Don't get carried away because it can be over done and you can get too much outward push on the sheet-metal. After just a few back & forth rolls of the bowling ball, stop and turn the fender over and see how much you've accomplished, if anything, because you're being so careful and frugal with your rolling. I found out that the bowling ball is not heavy enough to make a big difference by itself and so I began to apply pressure as I rolled it and then the dents really started responding; not with my body weight but just with my arm strength.

It came in handy nearer the factory bends/seams. Just roll it back and forth as described with the bowling ball.

Anyways after many, many, many rolls and flipping over and looking and rolls and flipping over and looking, I finally got to where I think is a pretty reasonable result.....

I hope this helps someone in the future and maybe save them a little money and also give a sense of pride that you fixed it yourself.......now what do I do with all this sand? lol

|