| Feel free to delete this because of NZR but I wanted to show everyone these cars are not that difficult to work on and share a lot of commonality among other nissan/infinity models. This is also a reminder that it doesn't take a big name shop to get some serious shit done - blue/white collar guys like you and me can do it! I have owned my 09' GTR since August of last year and bought it with just a few things done to it. I had some downtime between thanksgiving and christmas of last year so I decided I wanted to do a quality build on the GTR. Here we are pulling it in

I adore my MaxJax with all my heart. I do not know how I would function without it

I began by pulling the splash shields and the front bumper

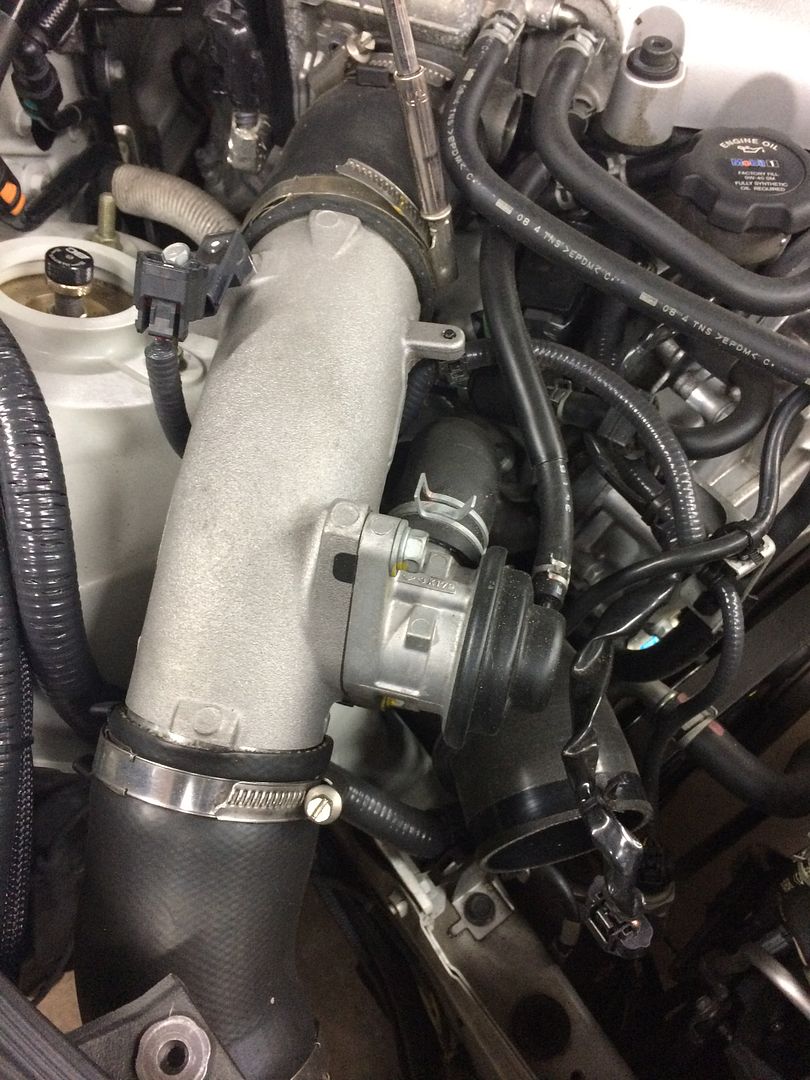

Charge pipes coming off

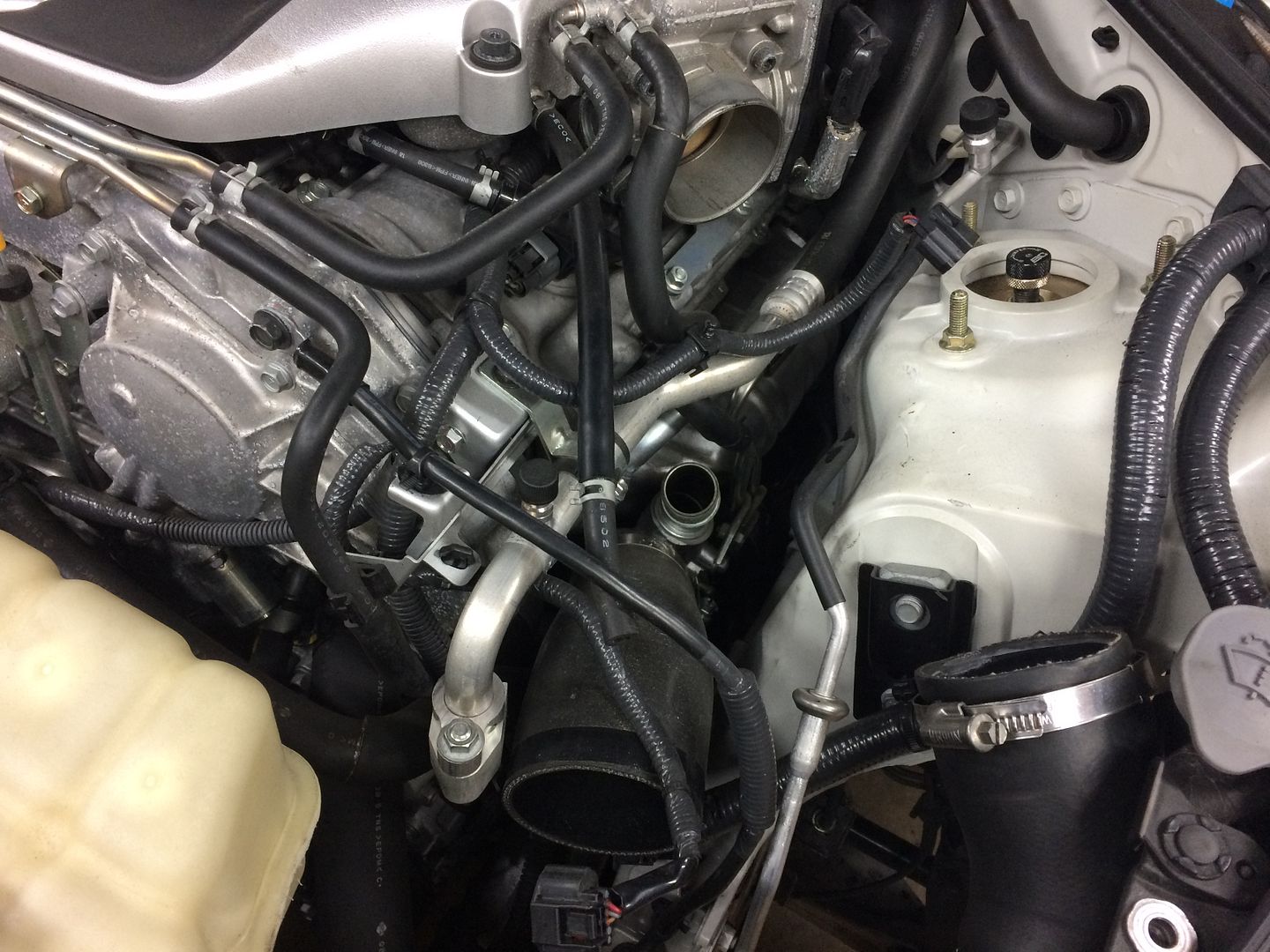

The radiator stays in the car this entire process. You'll just remove the expansion tank, and the radiator hoses

Time to start digging into godzilla

I removed the intake manifold because I was unsure I would have the proper ground clearance to get the engine out with the car as high as it would go. On the GTR, the engine MUST come out of the bottom!

Next, different from the Z32 - the engine harness actuallys stays with the engine when you're pulling it. The ECU is located in the same area in the footwell and by pulling some of the shields, you can undo the connectors and pull them through the firewall and rest them on the engine

Next, I decided to make some factory engine slingers with some elbow grease.........and plasma

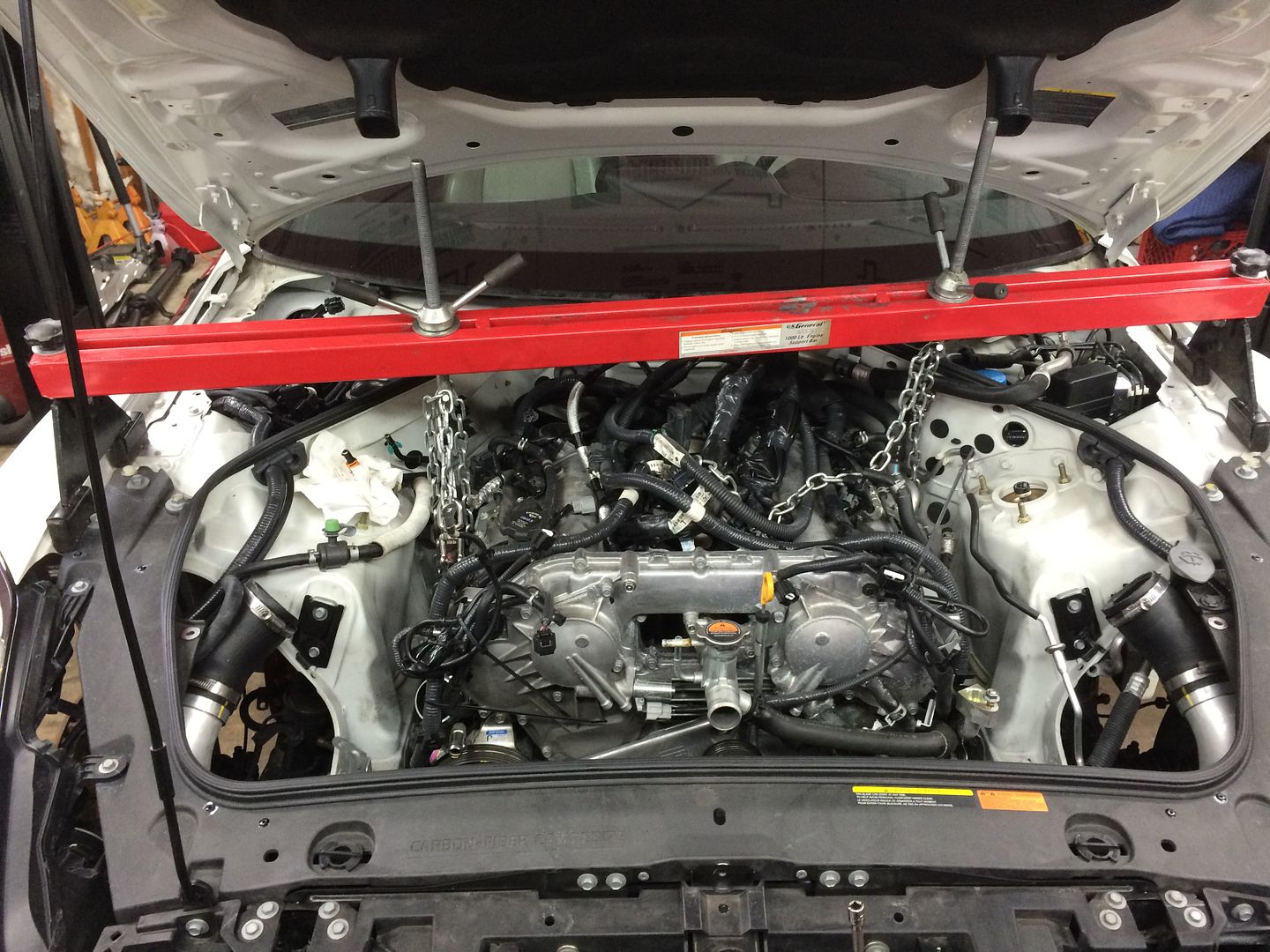

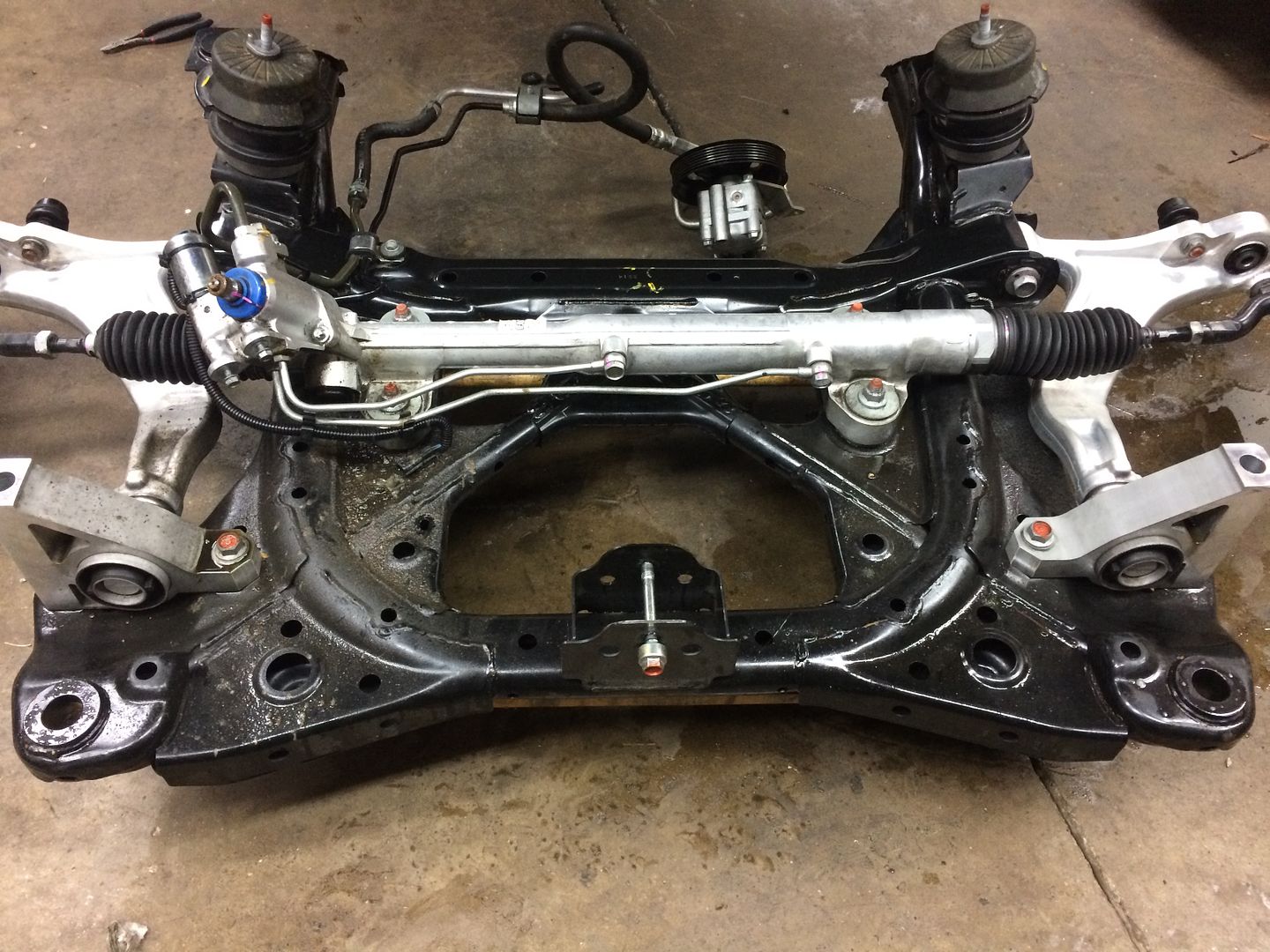

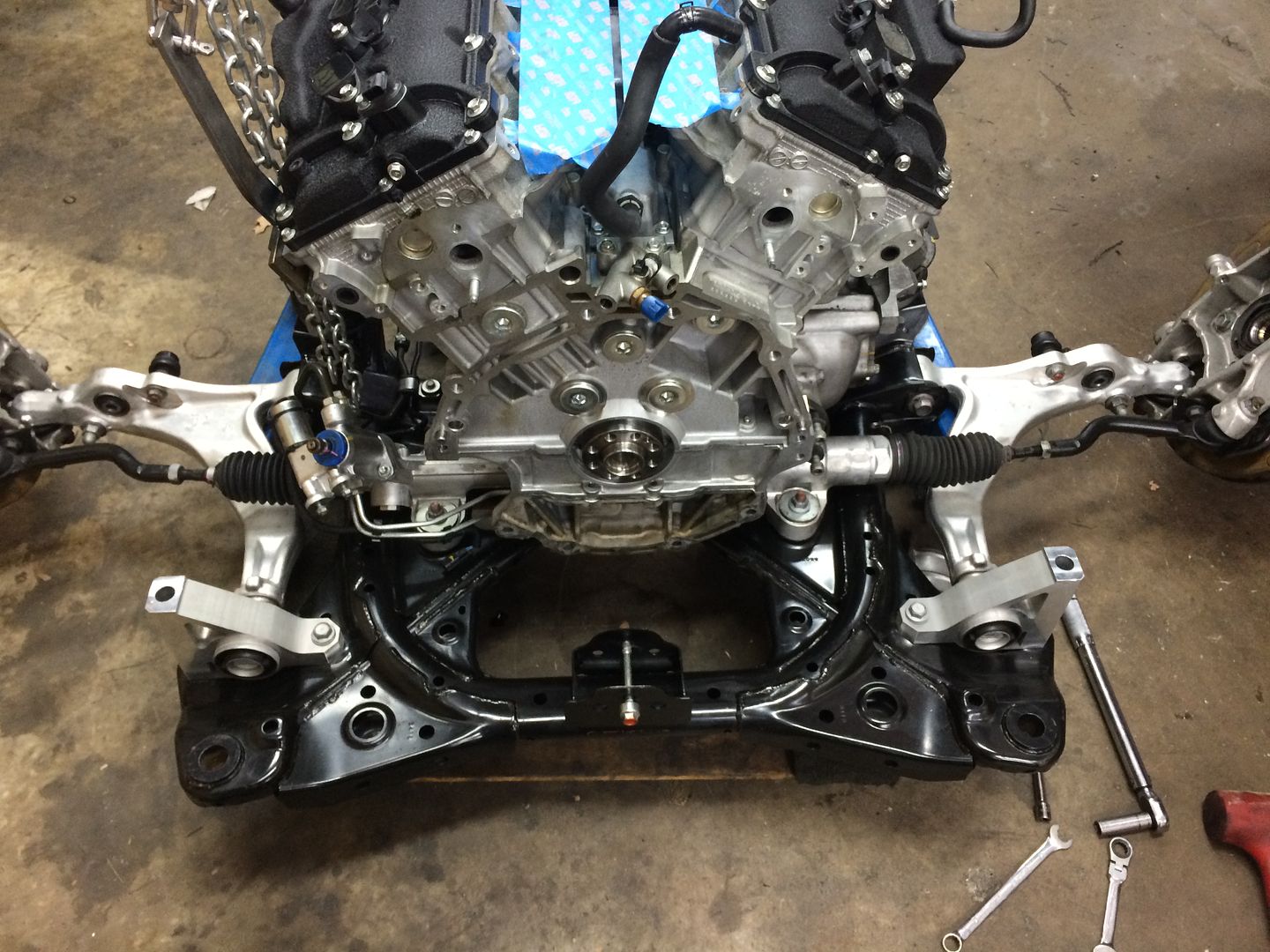

Here's where it gets a little tricky. I used the engine spanner bar to support the engine while I worked underneath. The engine comes out still attached to the subframe so I used the spanner bar to help lower the engine onto a movable dolley

I didnt take any pictures but for the suspension you just undo the lower shock mounts, unbolt the calipers and hang them with a bunjee cord. Also not pictured I dropped the exhaust, and both driveshafts. The GTR is a transaxle style car meaning the trans sits in the rear end. It does however, have a bell housing - similar to a corvette setup. I lowered the engine onto the dolley and then raised the car up on the lift

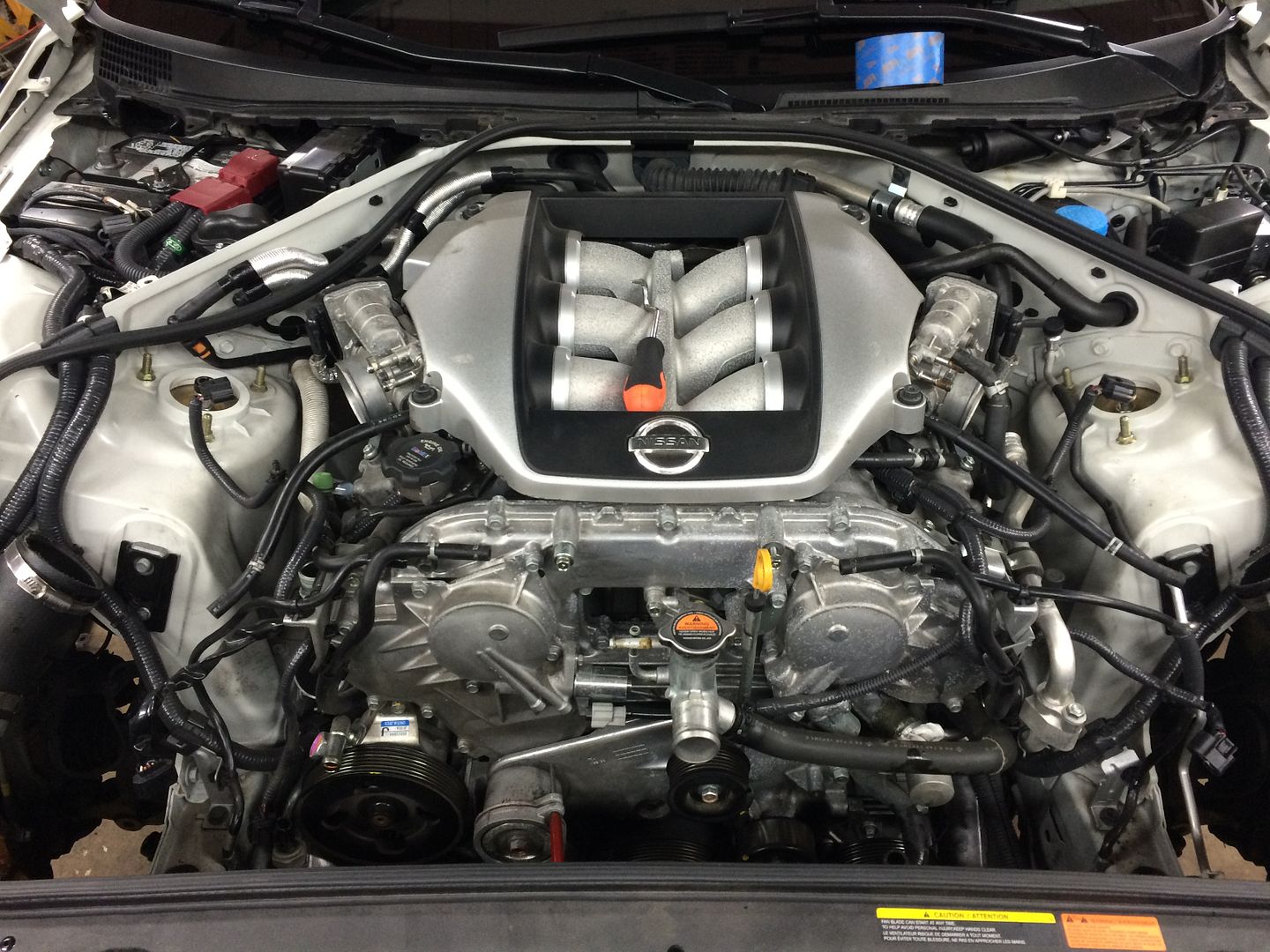

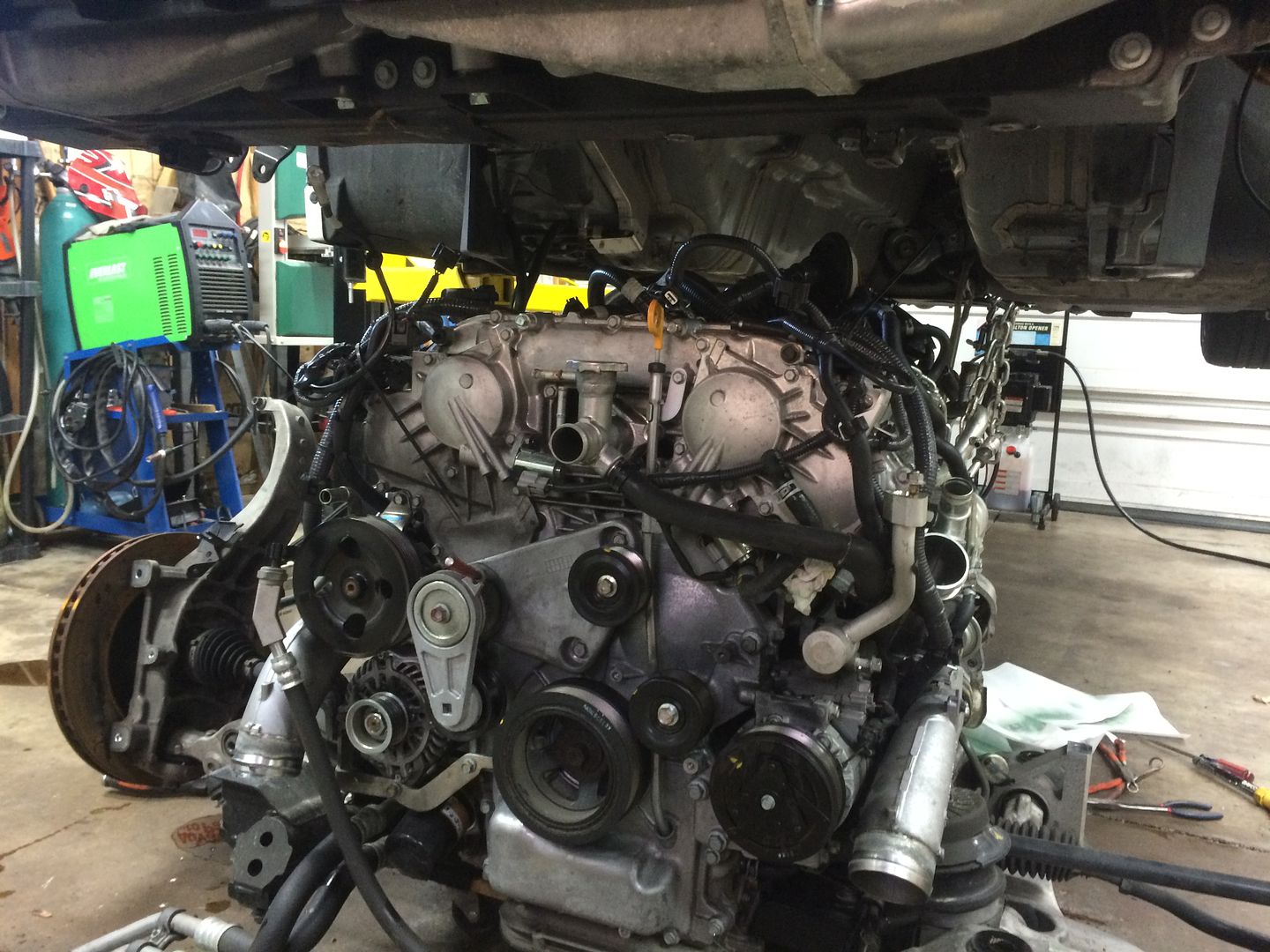

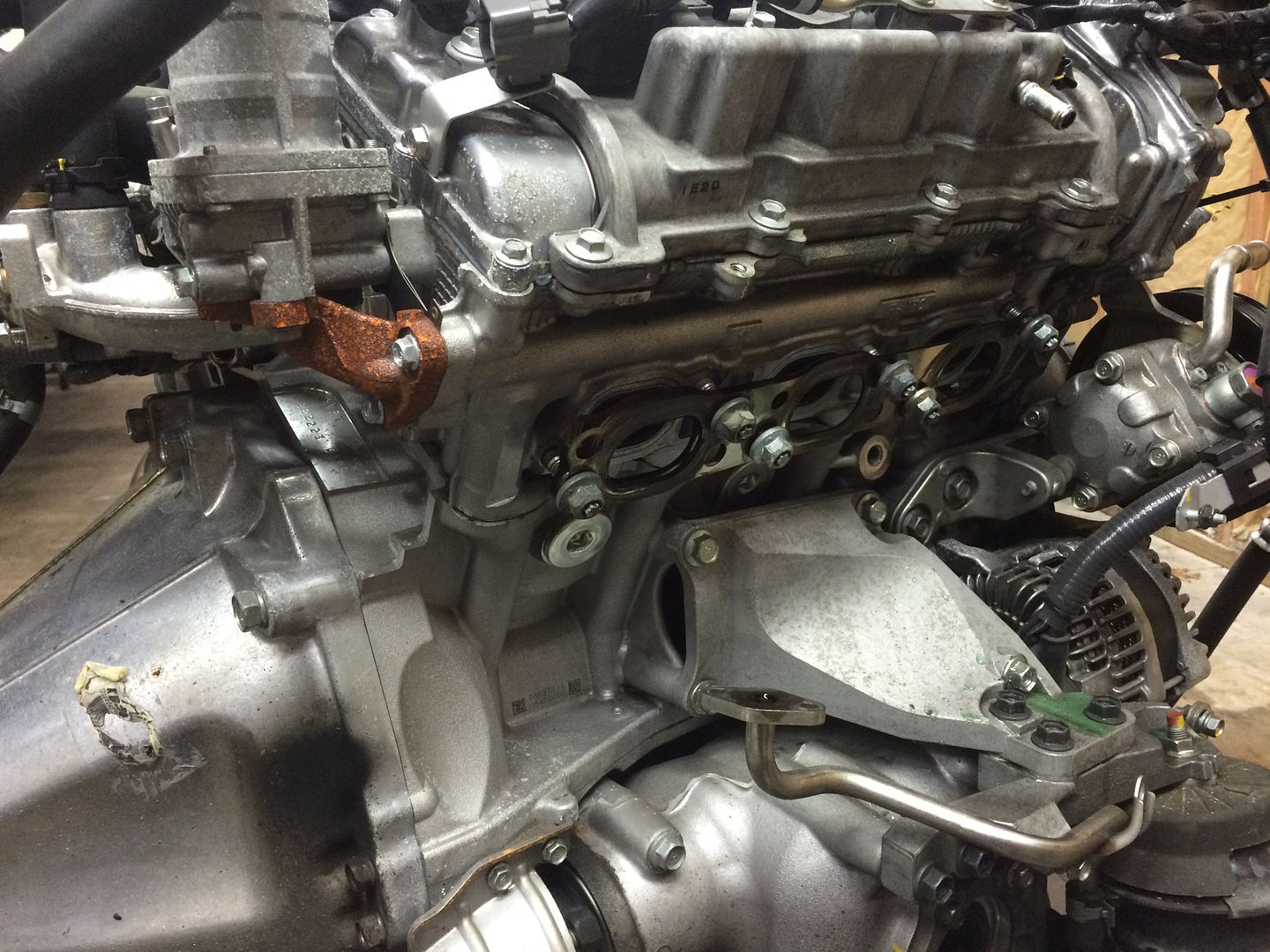

The VR38 in all its glory

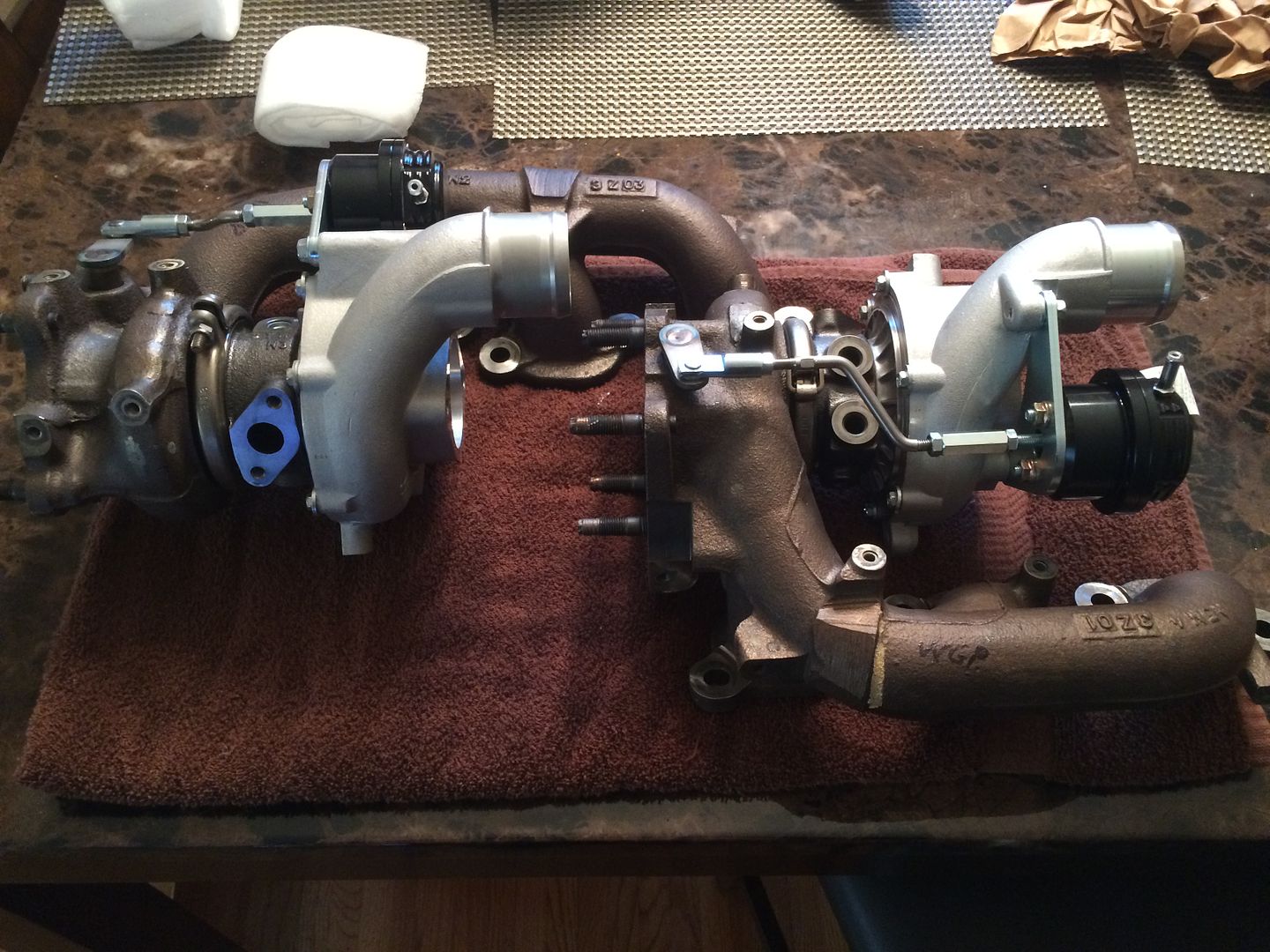

Here's the dinky turbo system on the driver's side

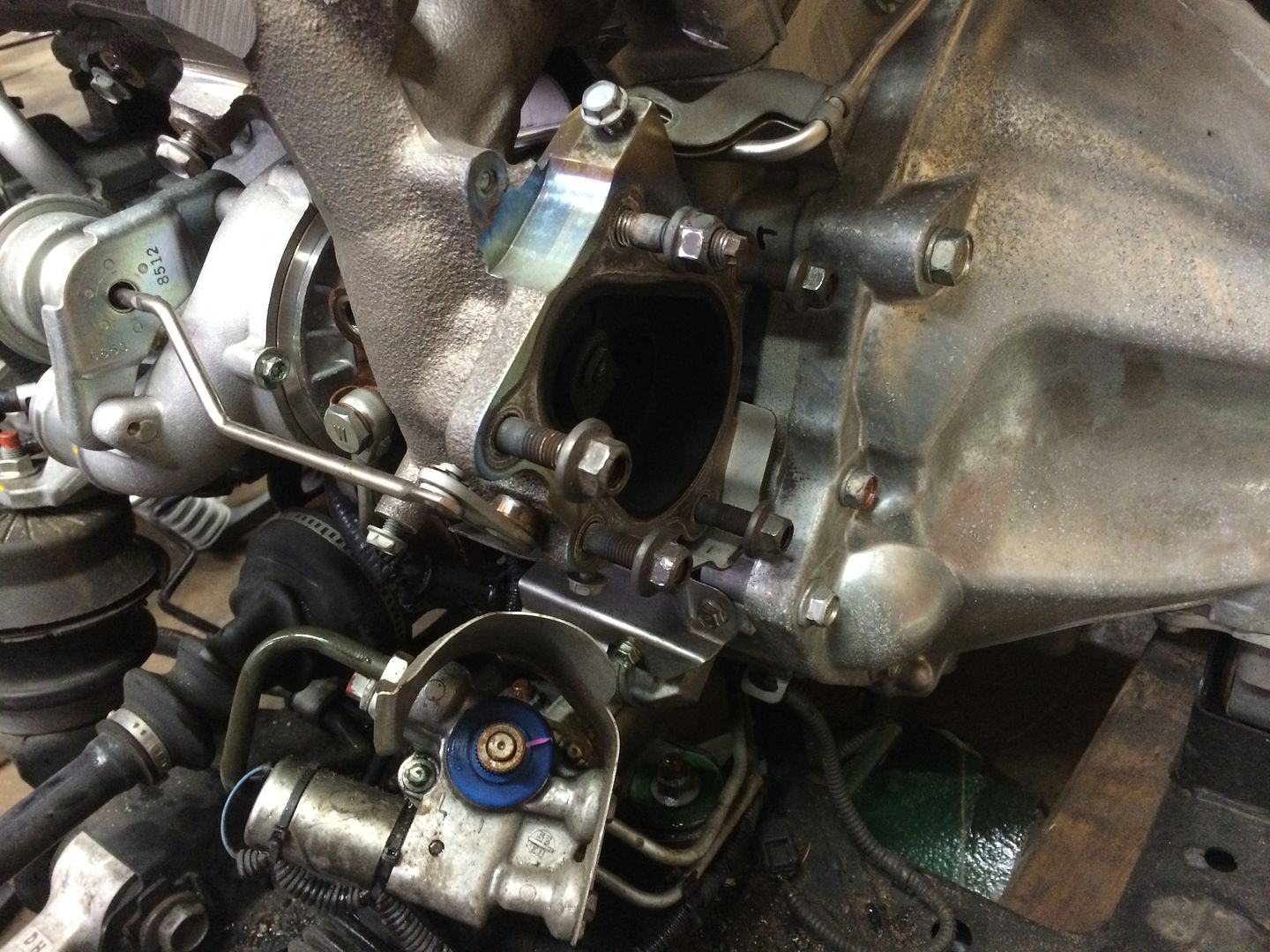

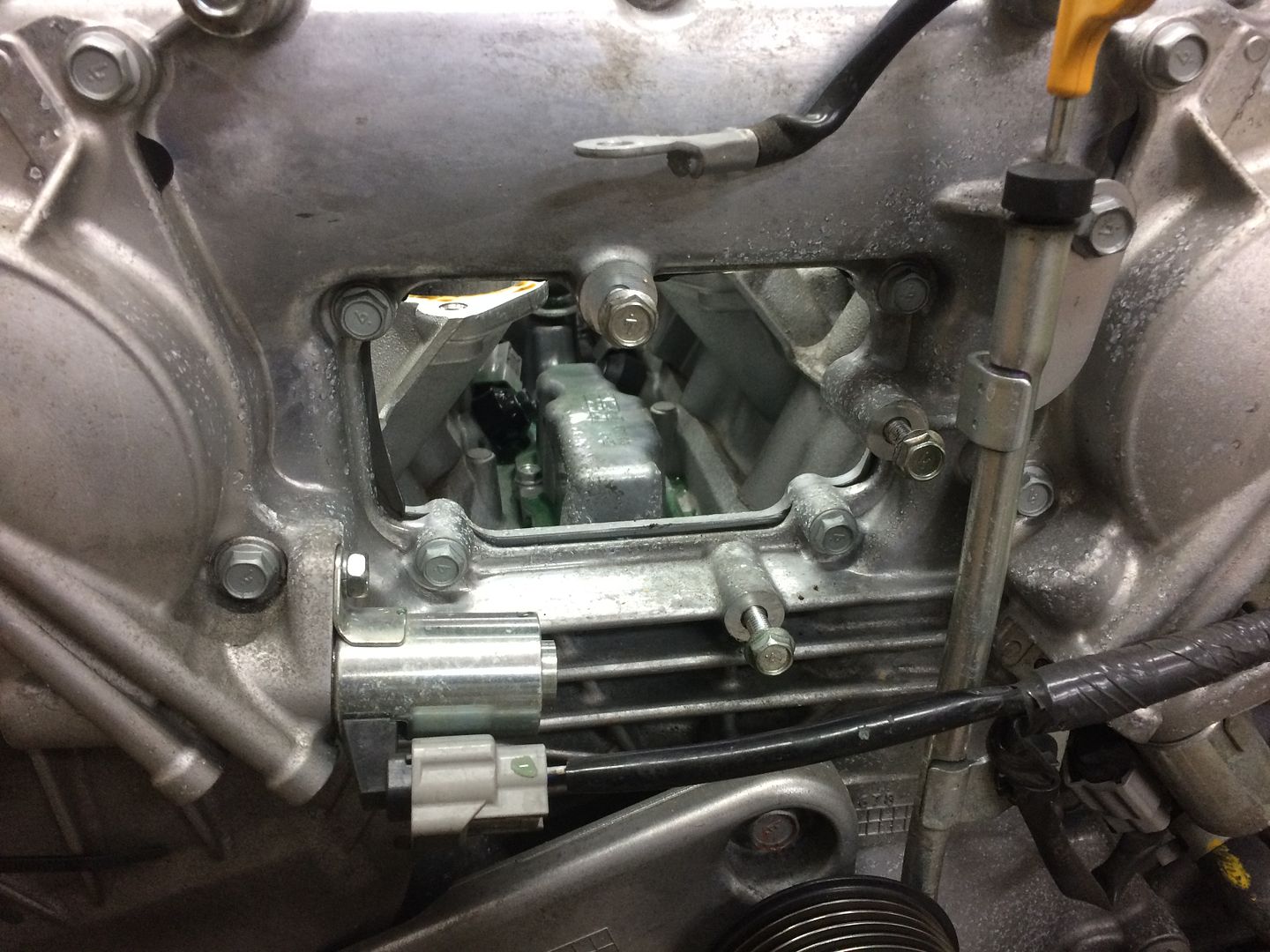

Here's the bell housing setup I mentioned

Passenger side turbo system

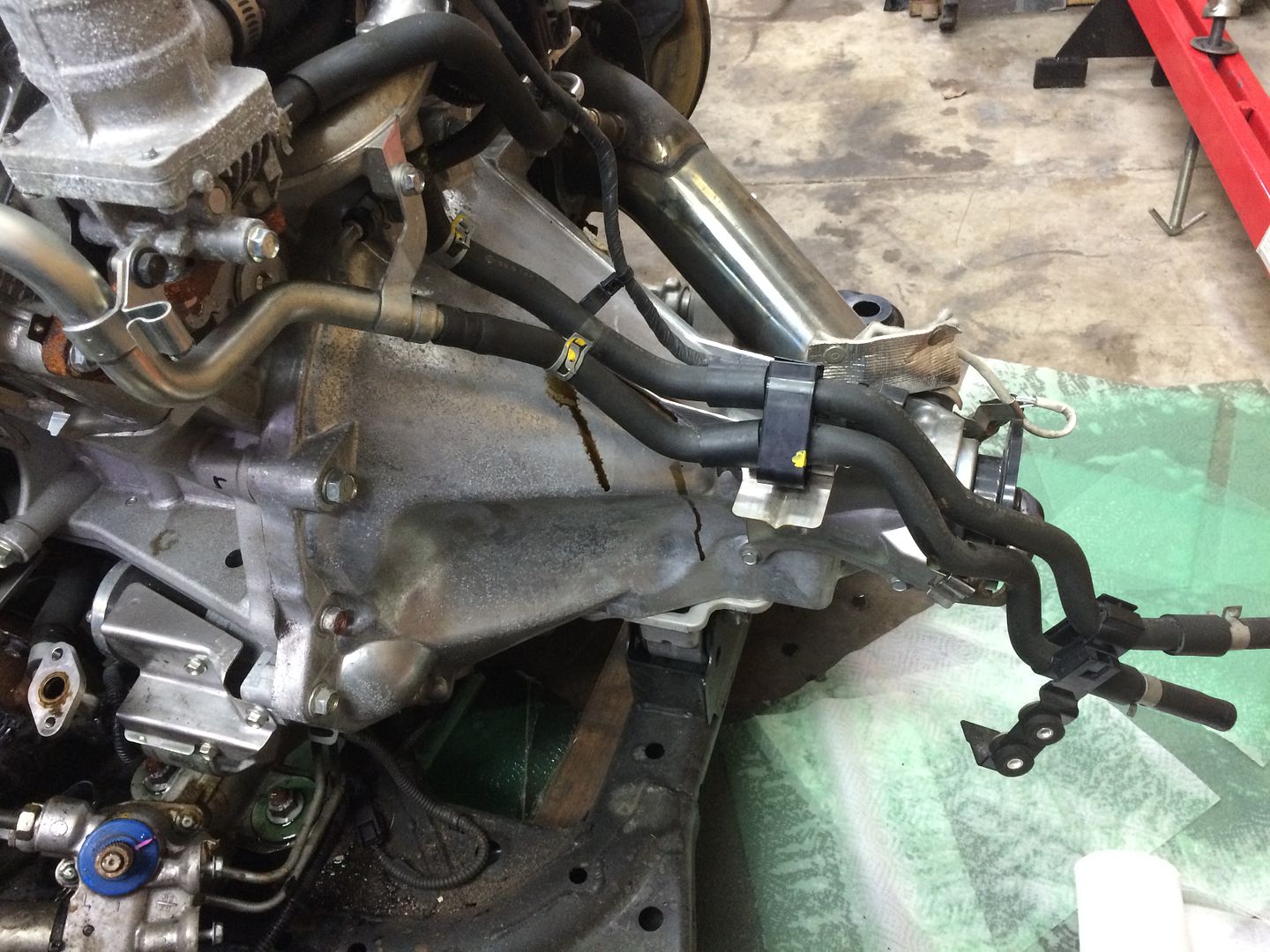

Similar EGR system and coolant routing

Turbo off

Lower intake manifold removed

The front coolant pipe passes through the front timing system here

The coolant pipe travels back and "Y's" apart

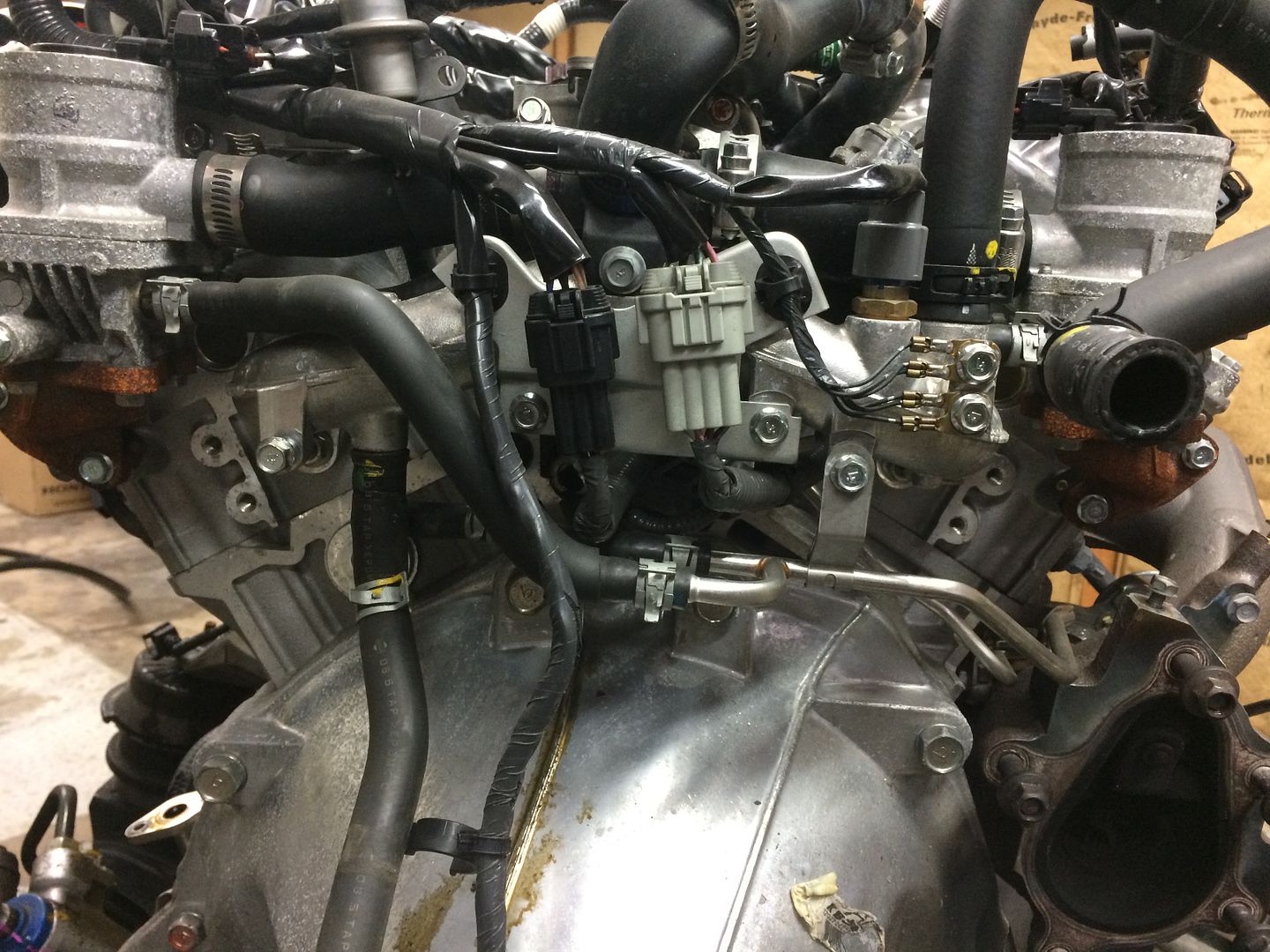

This is the oil pressure sensor and the feed connections for both the turbos

Here's the lower front of the engine

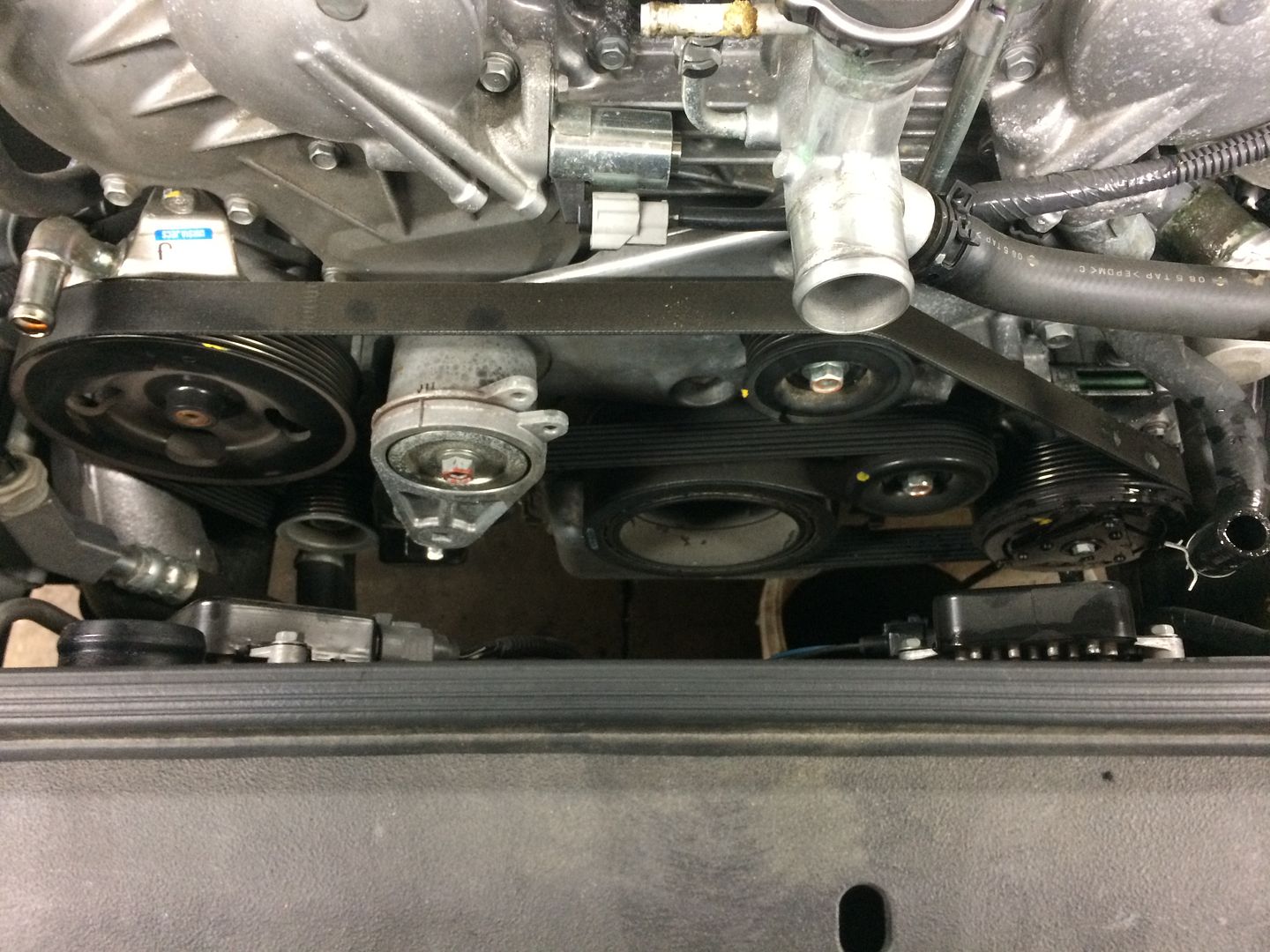

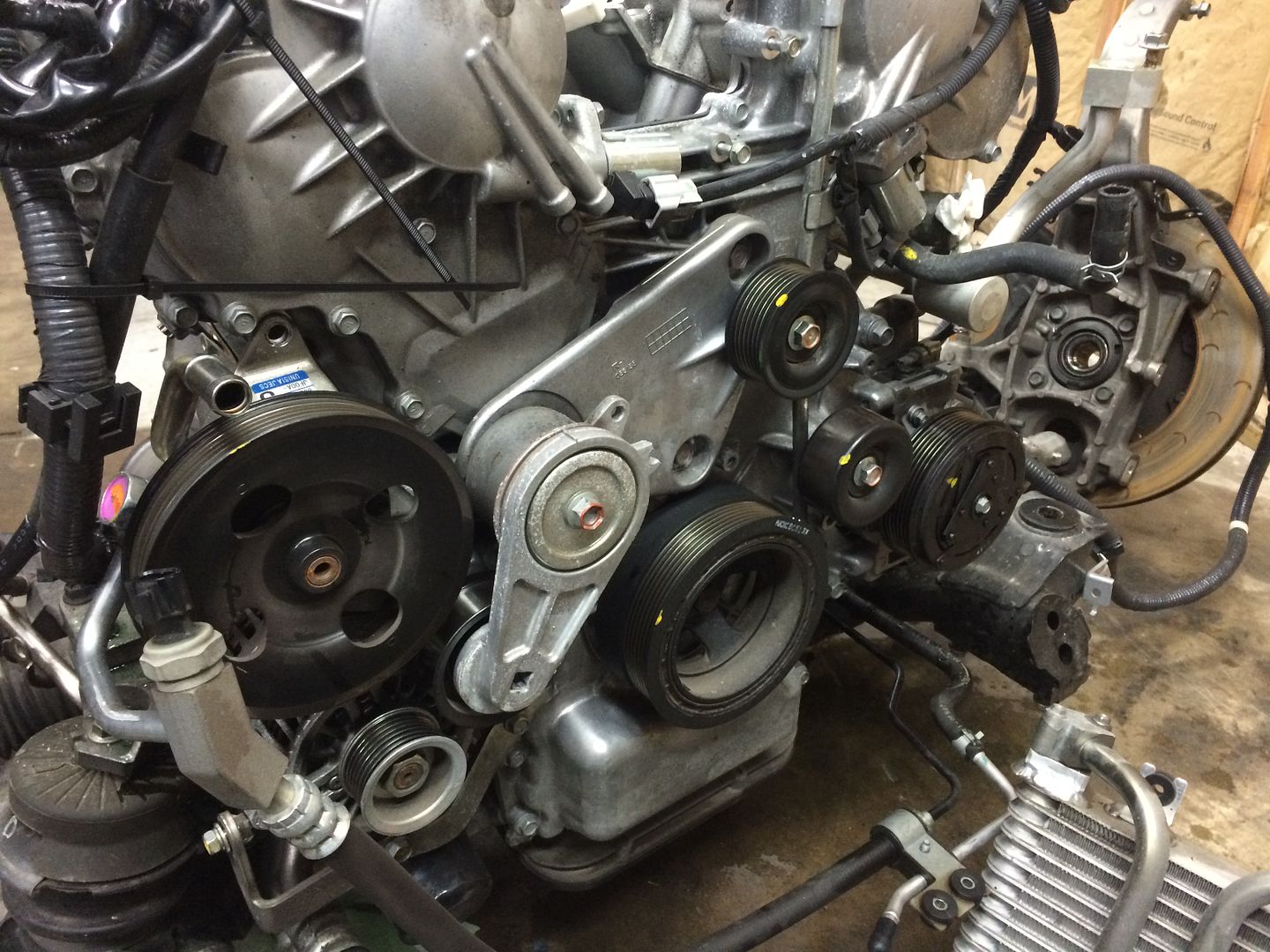

I got the alternator, power steering, and AC stuff removed a long with the starter and pulled the wiring harness off of the engine

This is the oil filter tree which has attachments for the OEM oil cooler

Now that I've got all the accessories off, I can unbolt it from the cradle and put the engine on the stand

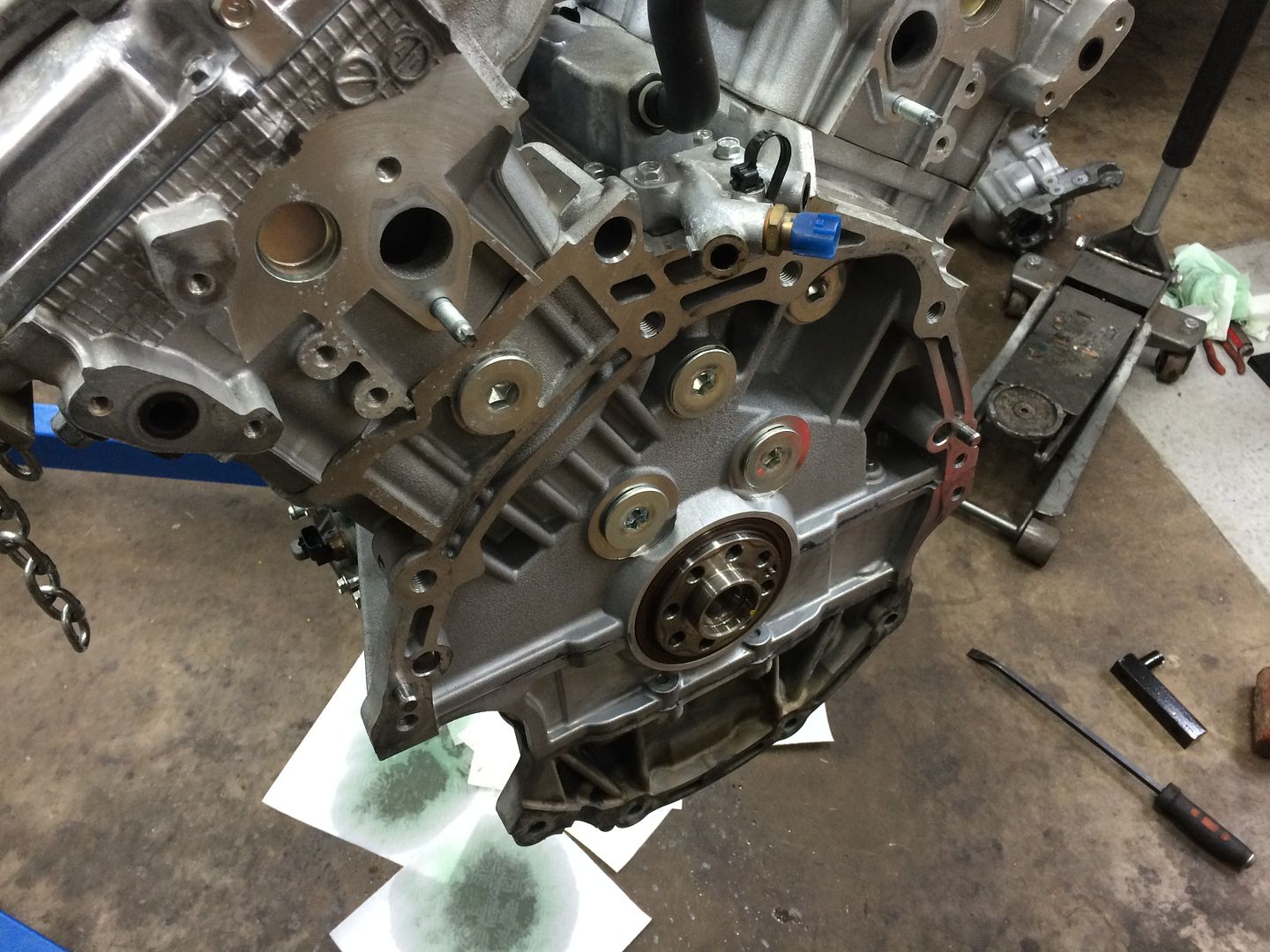

First I should probably get that pesky transfer case out of the way

And then I need to remove the bell housing, it works kind of like a flexplate on regular automatics

Now its looking pretty good!

Time to start taking the engine apart

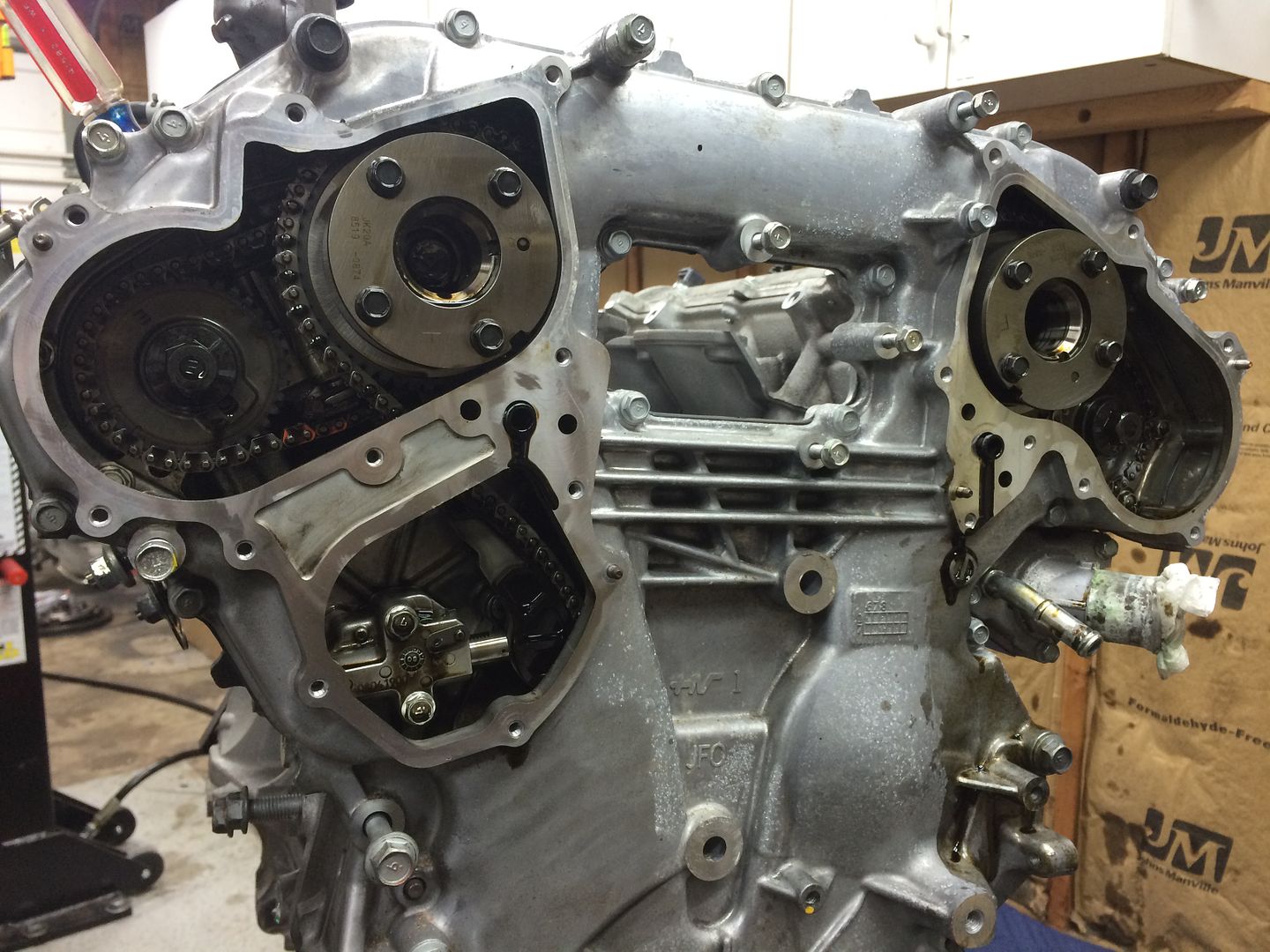

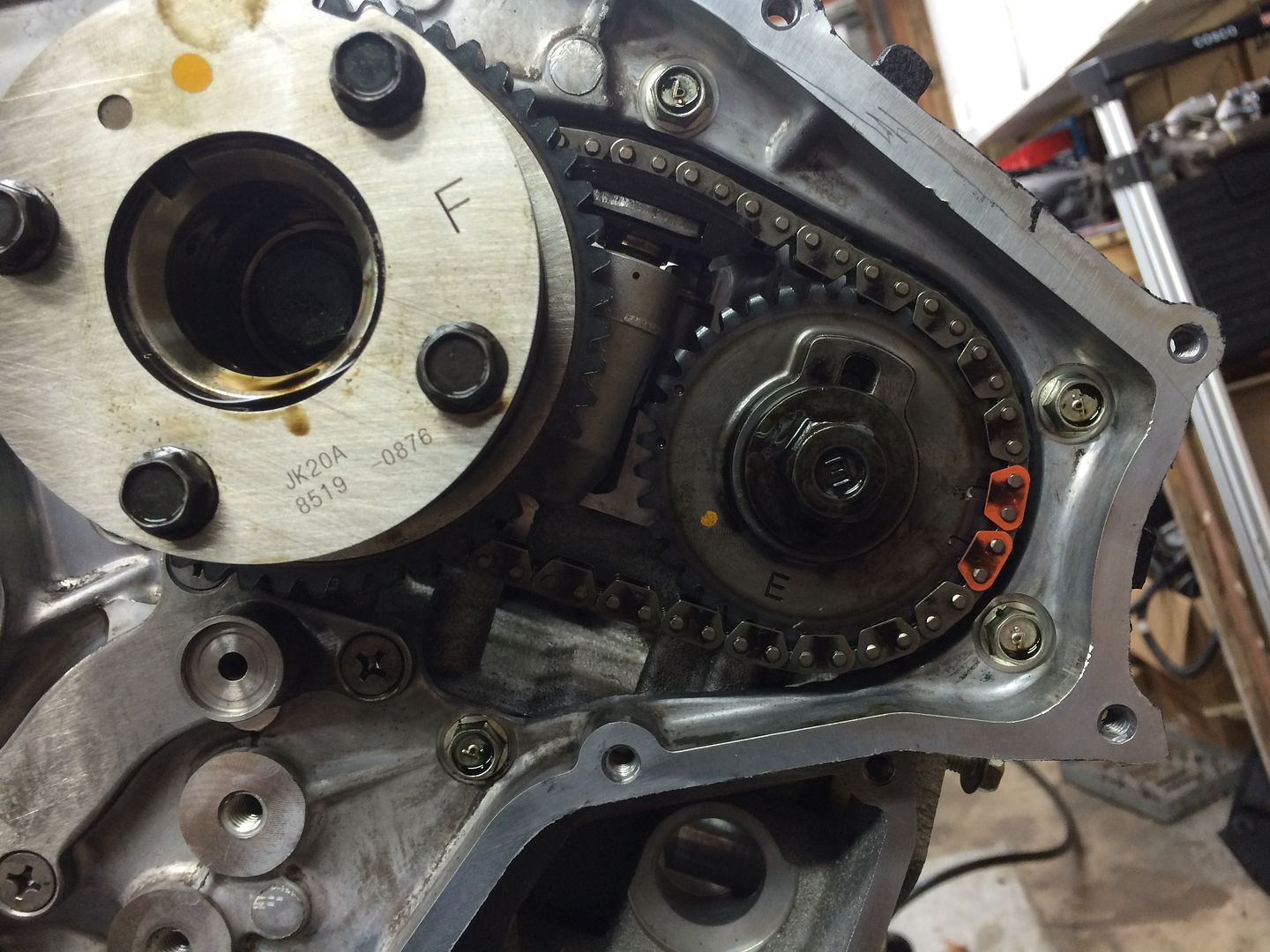

The timing cover has two secondary covers which house the VVT circuits. They use a solenoid to direct oil which acts as a hydraulic system to activate the VVT

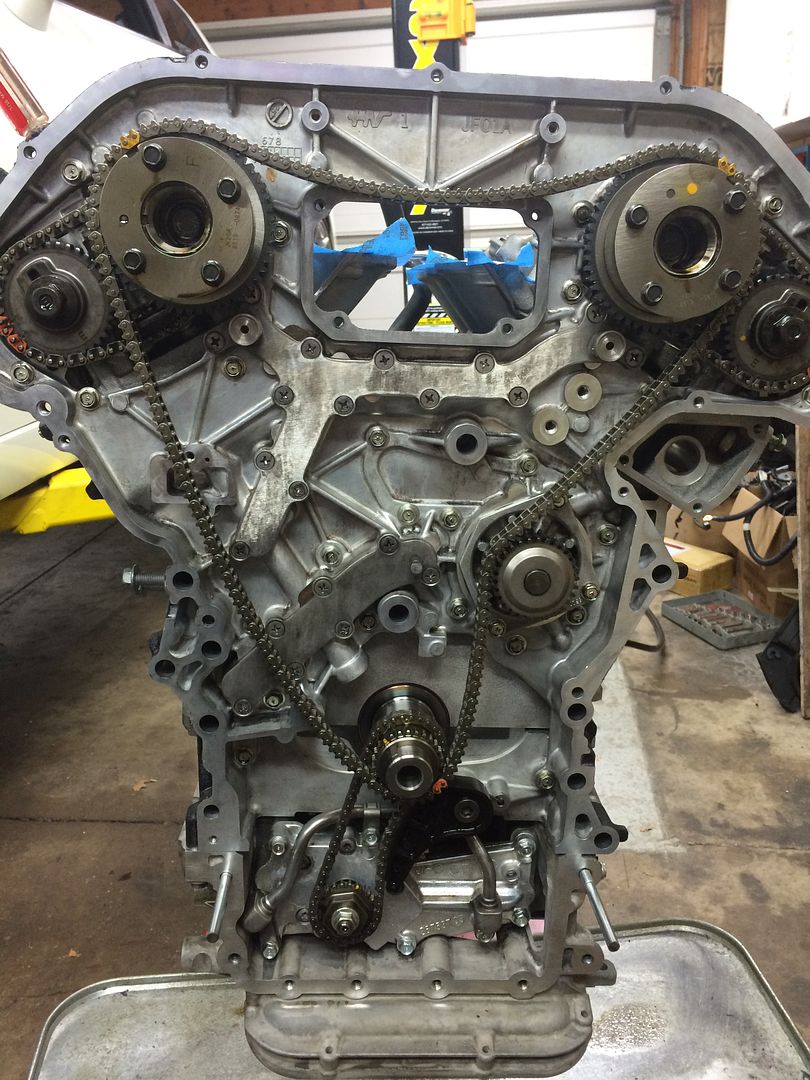

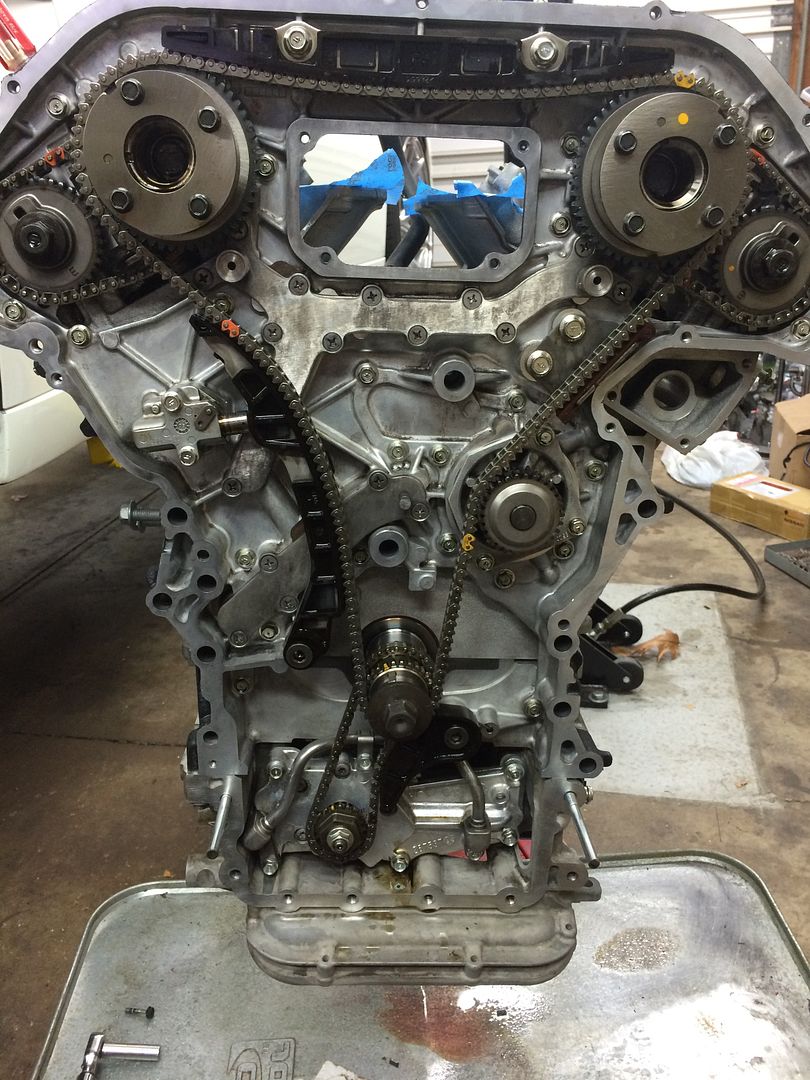

After removing the 25+ bolts that hold the front timing cover on, and significant prying - the cover comes off. Nissan uses RTV on the entire cover so its kind of a daunting process. The timing system looks like a convoluted mess, but its really not that bad.

Primary chain removed

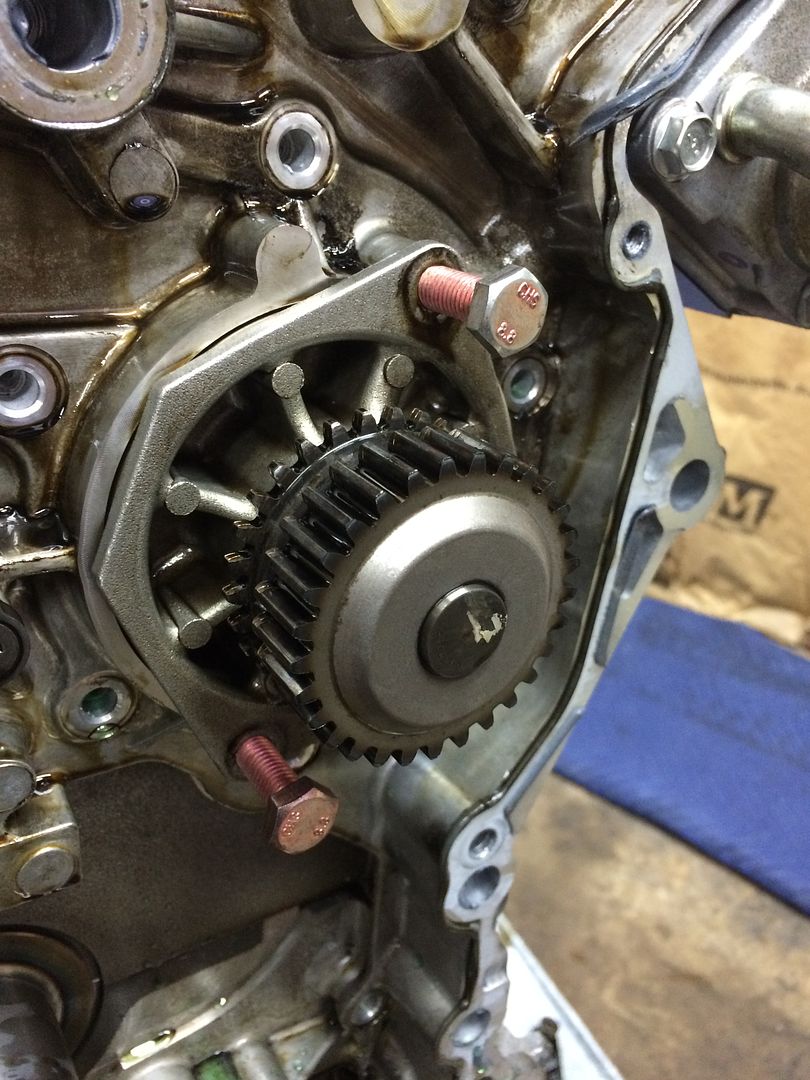

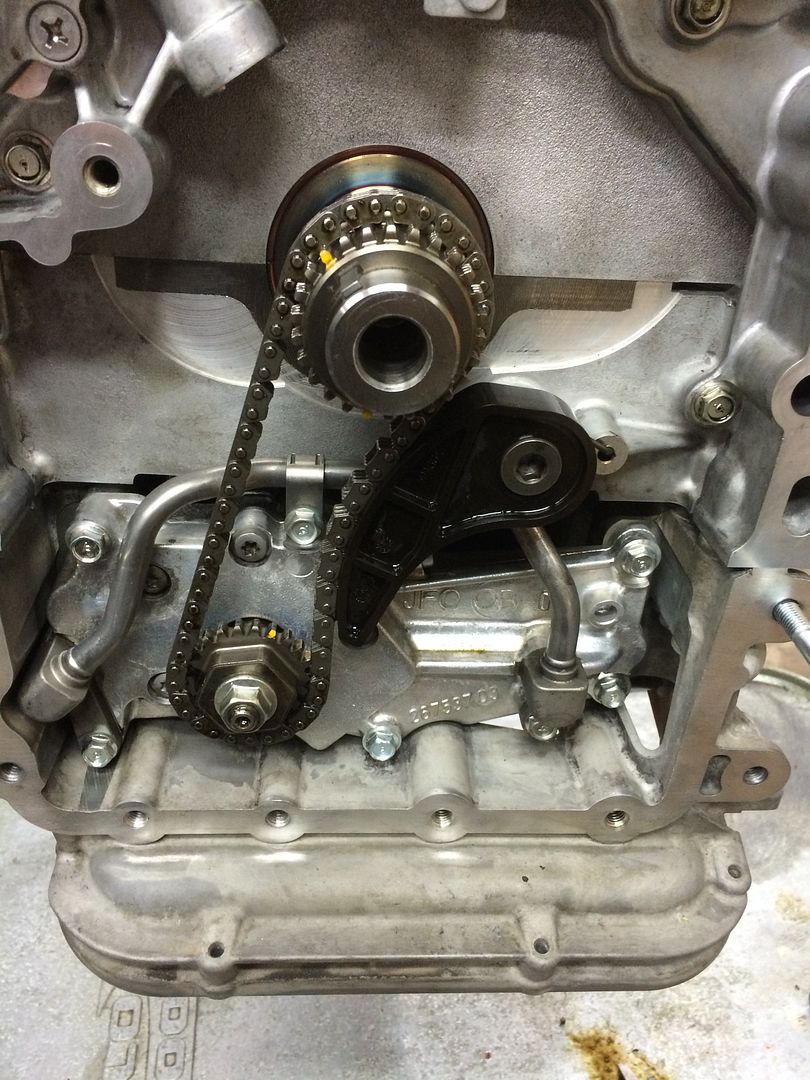

The oil pump is driven separately, and the intake/exhaust cam gears are mated on their own chains and tensioners

Next, lets go ahead and get access to the cams

Tensioners and chains removed

The water pump assembly can be pressed out by using larger bolts that thread into the mounting holes

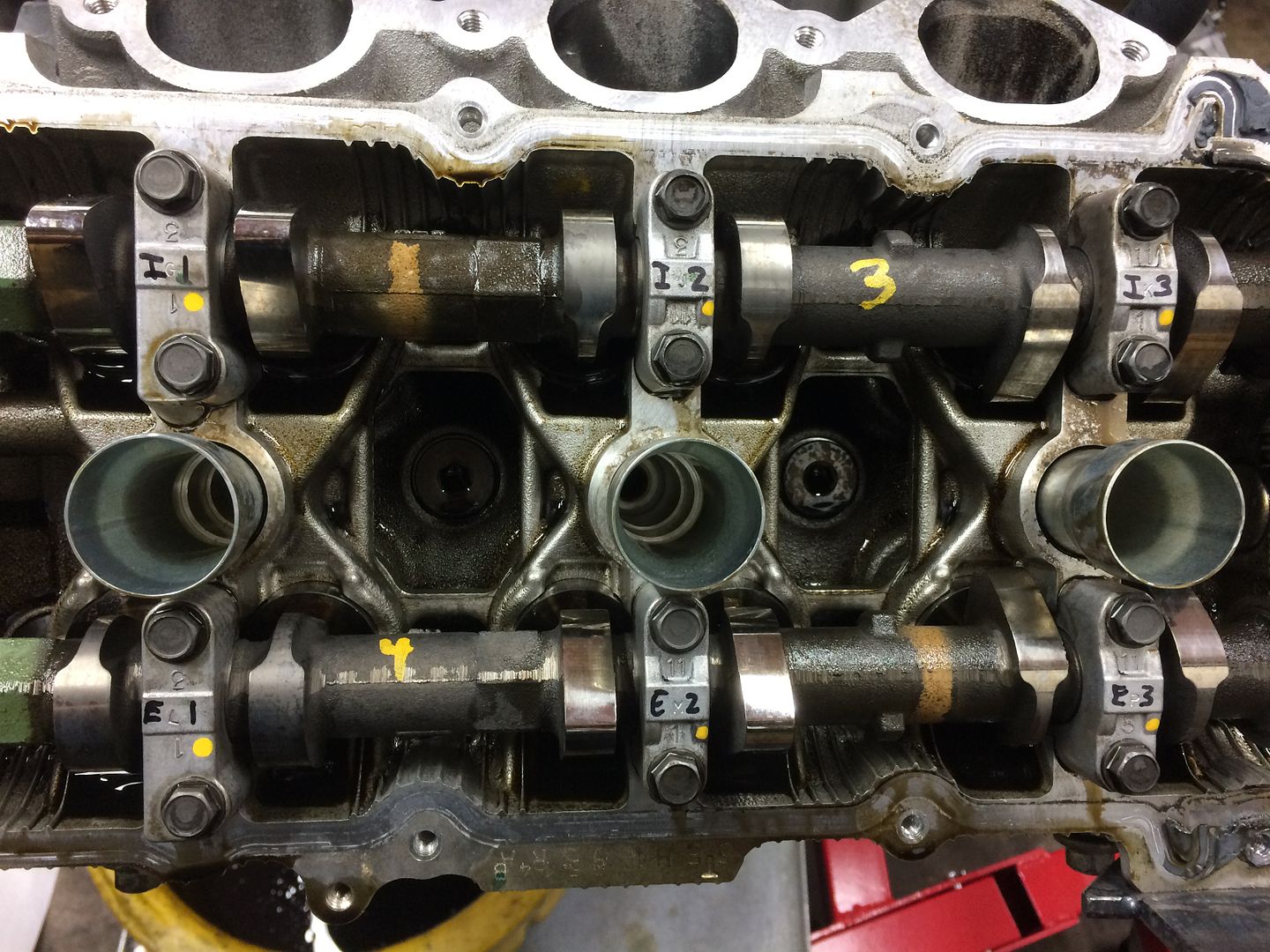

Labeling every cam cap and orientation

Cams out

And here's your entire valvetrain assembly

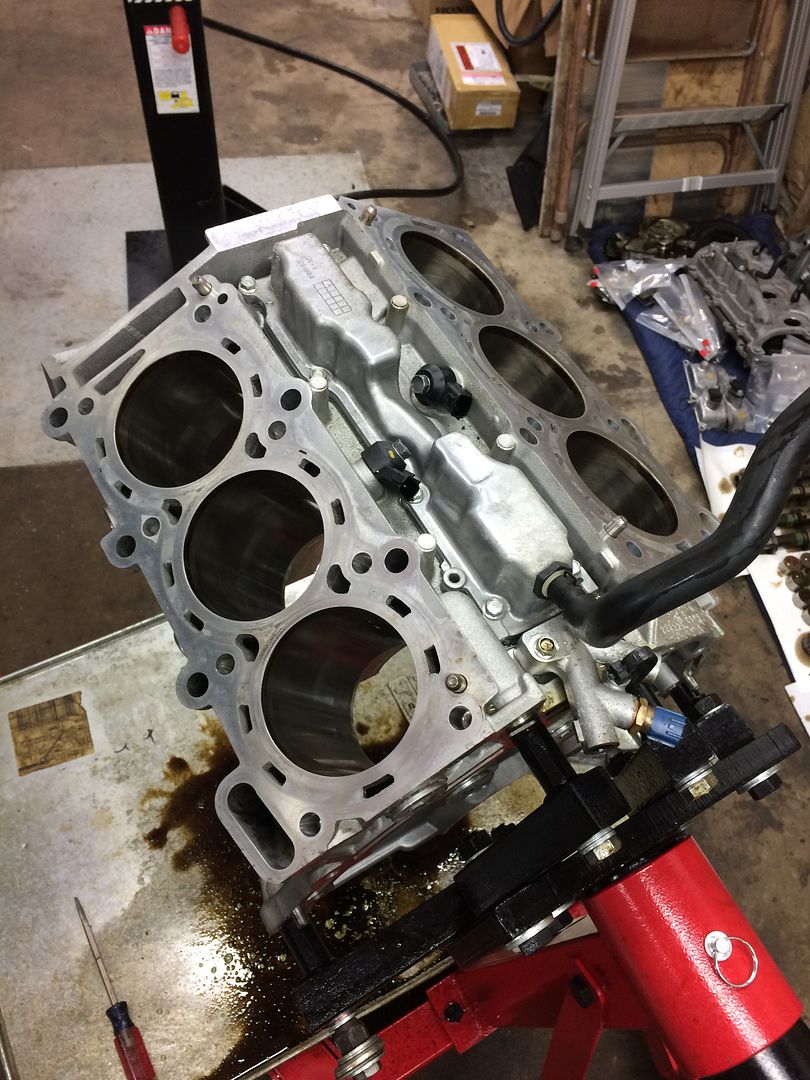

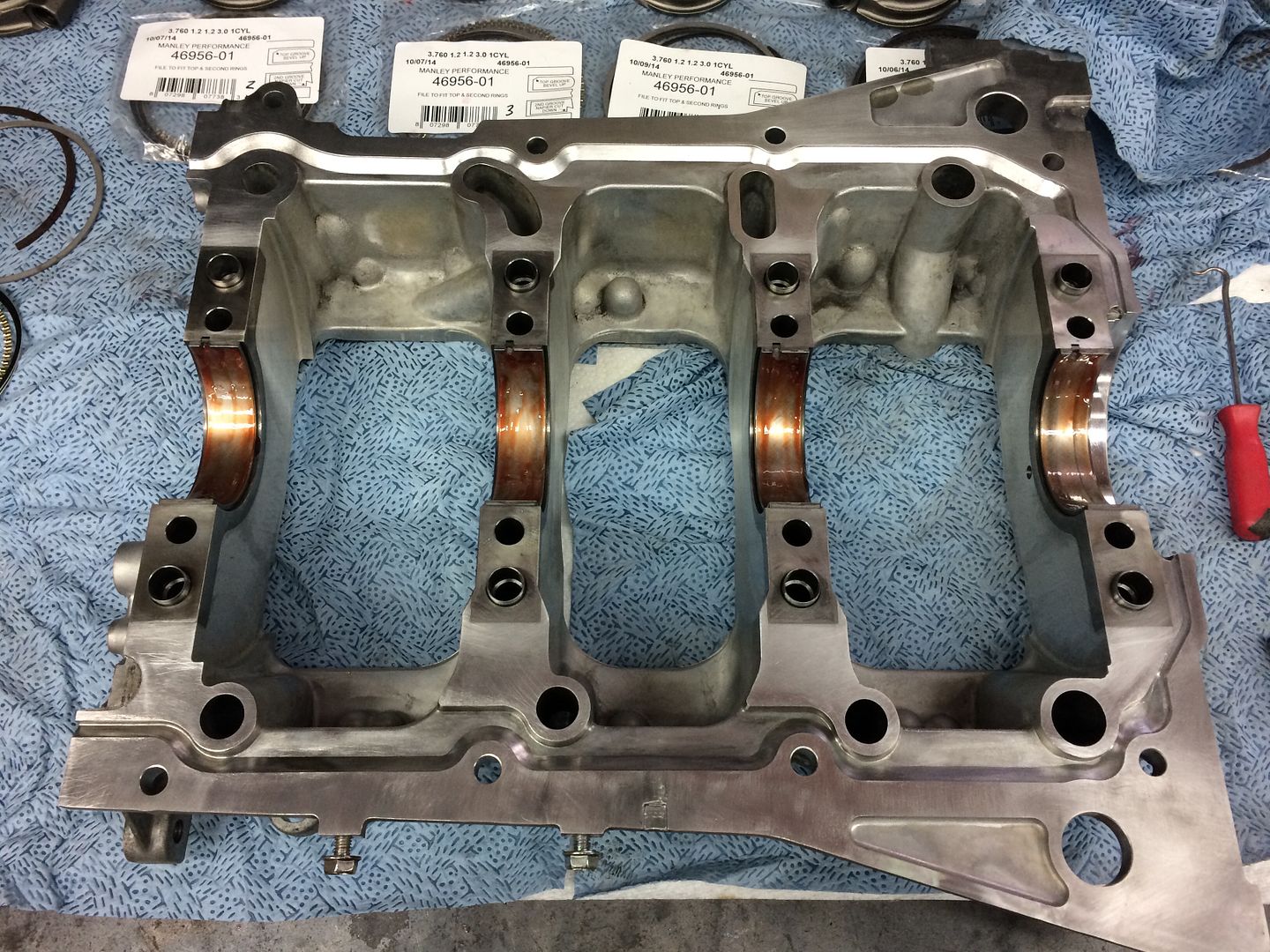

Now lets get to some shiny parts. For the shortblock, I went with Manley Drop-In pistons and Manley Turbo Tuff Rods. From the factory, nissan stamps the cylinder bore diameter by way of a "grade" There are only 3 grades available. So as long as you measure your cylinder and it still coincides with the grade diameter, these pistons go in w/out issue (although you should still check your piston to wall clearance)

So lets flip the engine and work on getting the factory stuff out

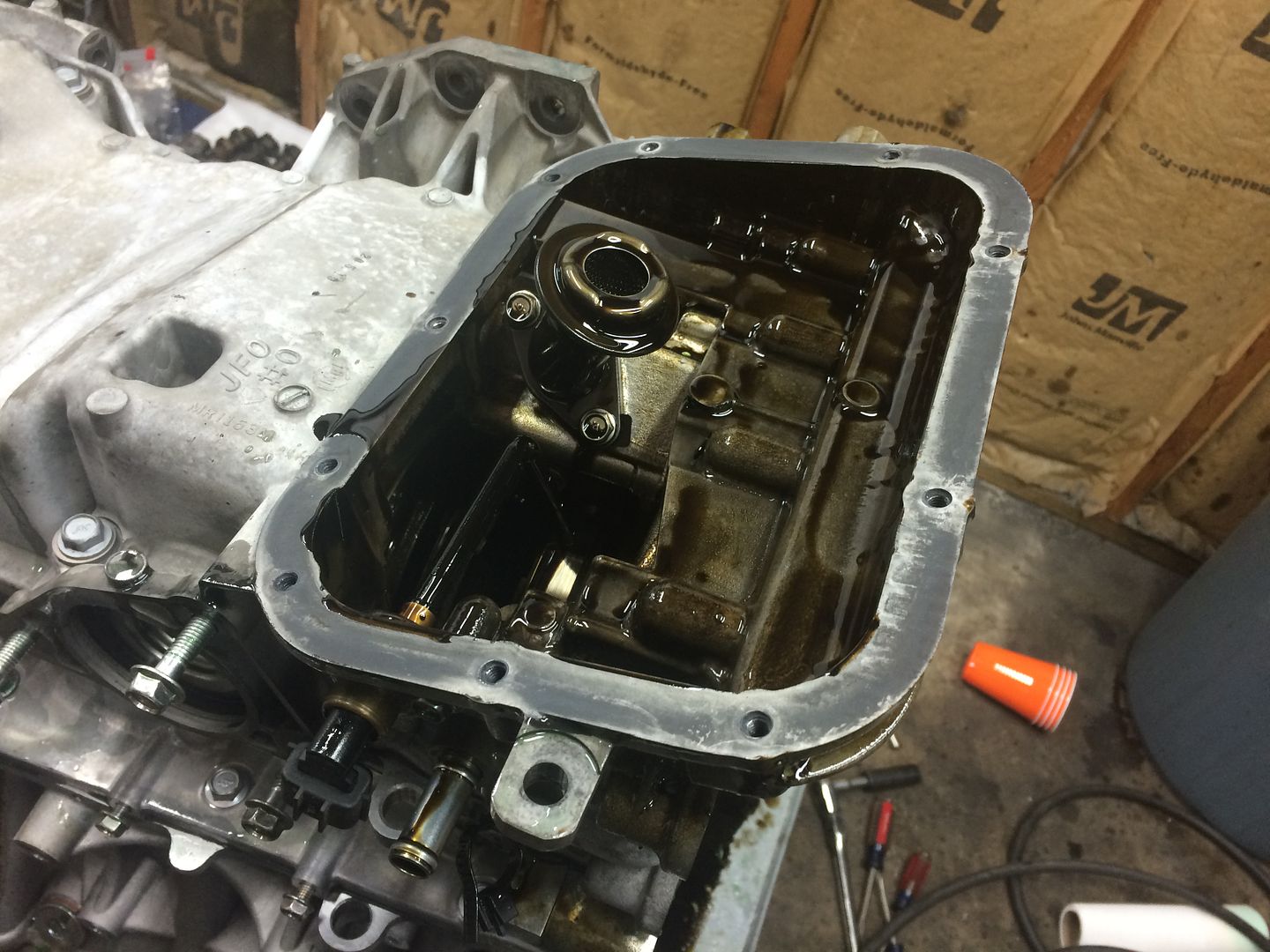

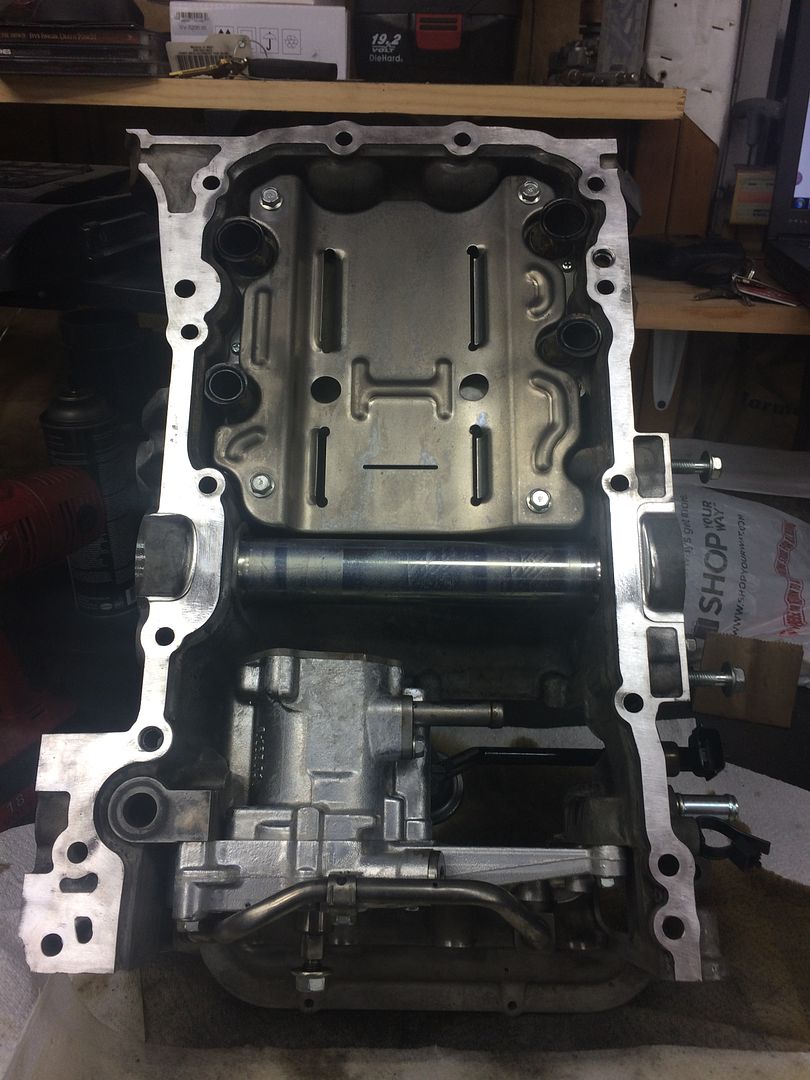

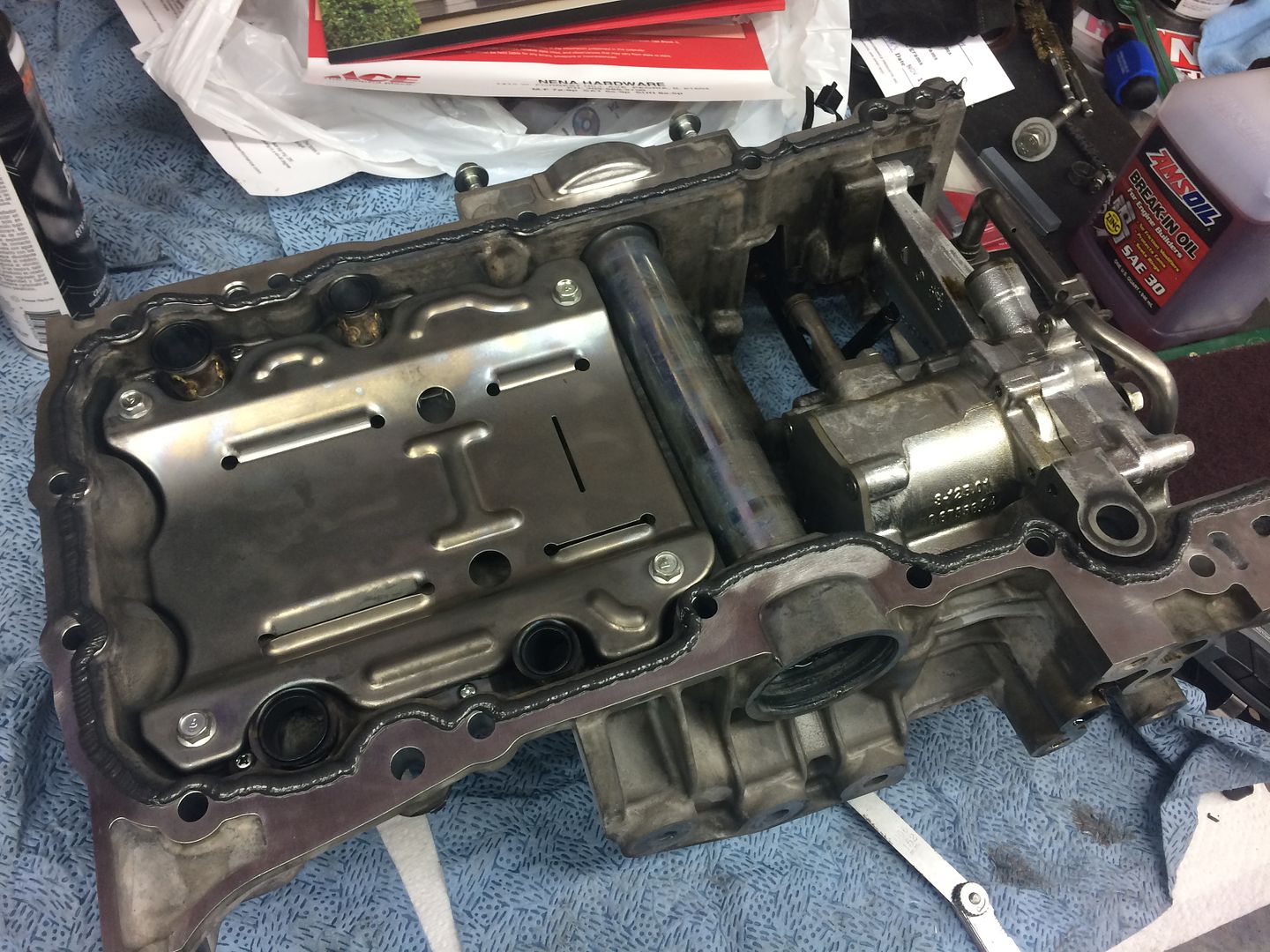

Nissans oil pan design really changed here. It starts with a small "sub" pan for the sump

You can see it down and to the right but the primary oil pan assembly its giant. It actually houses the oil pump so it all comes off in one assembly - kind of neat actually

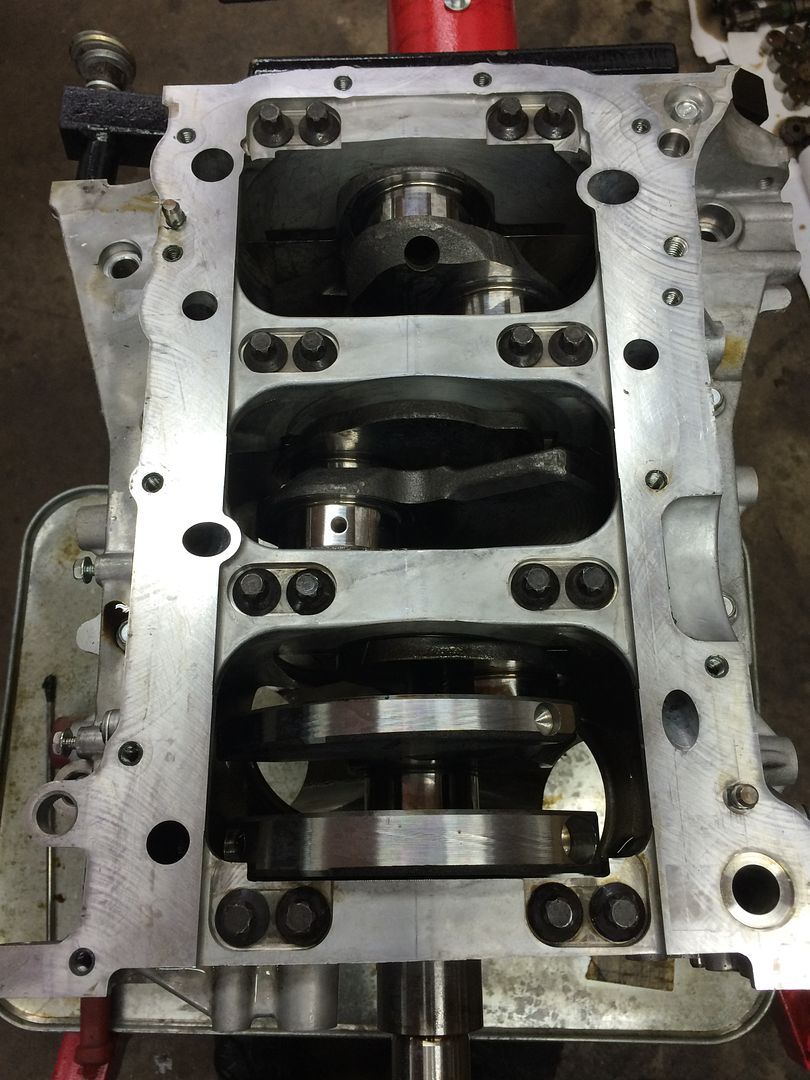

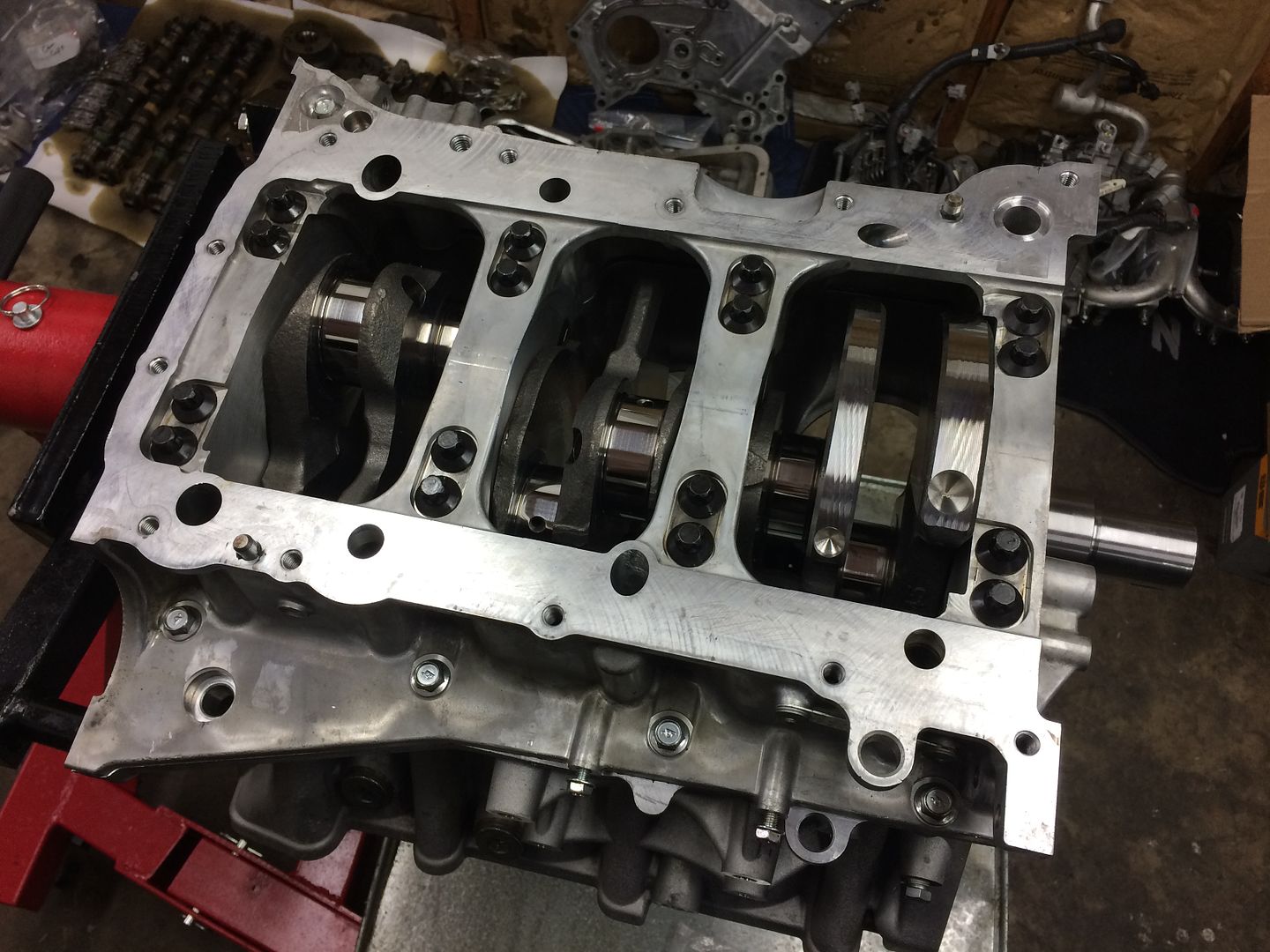

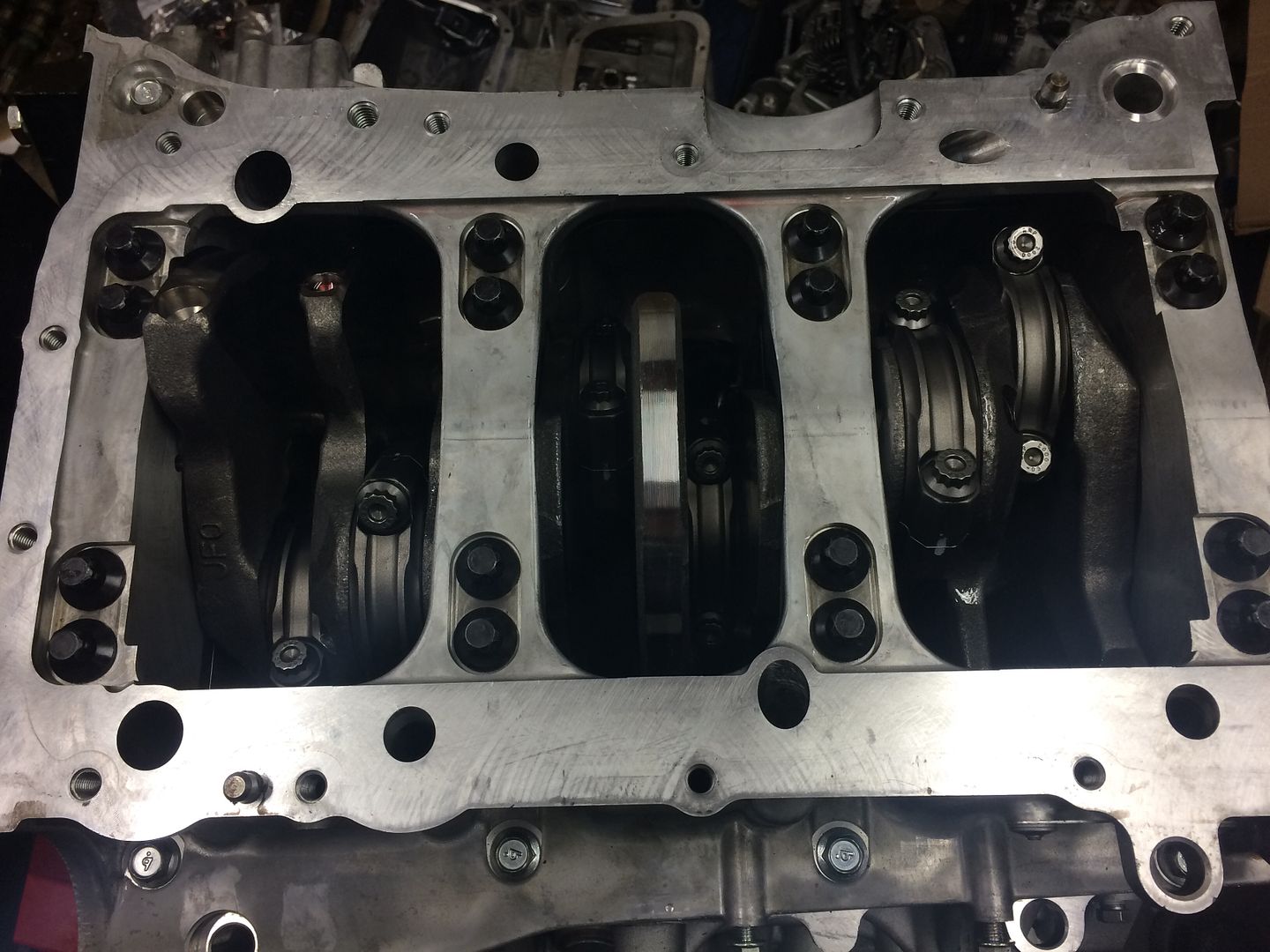

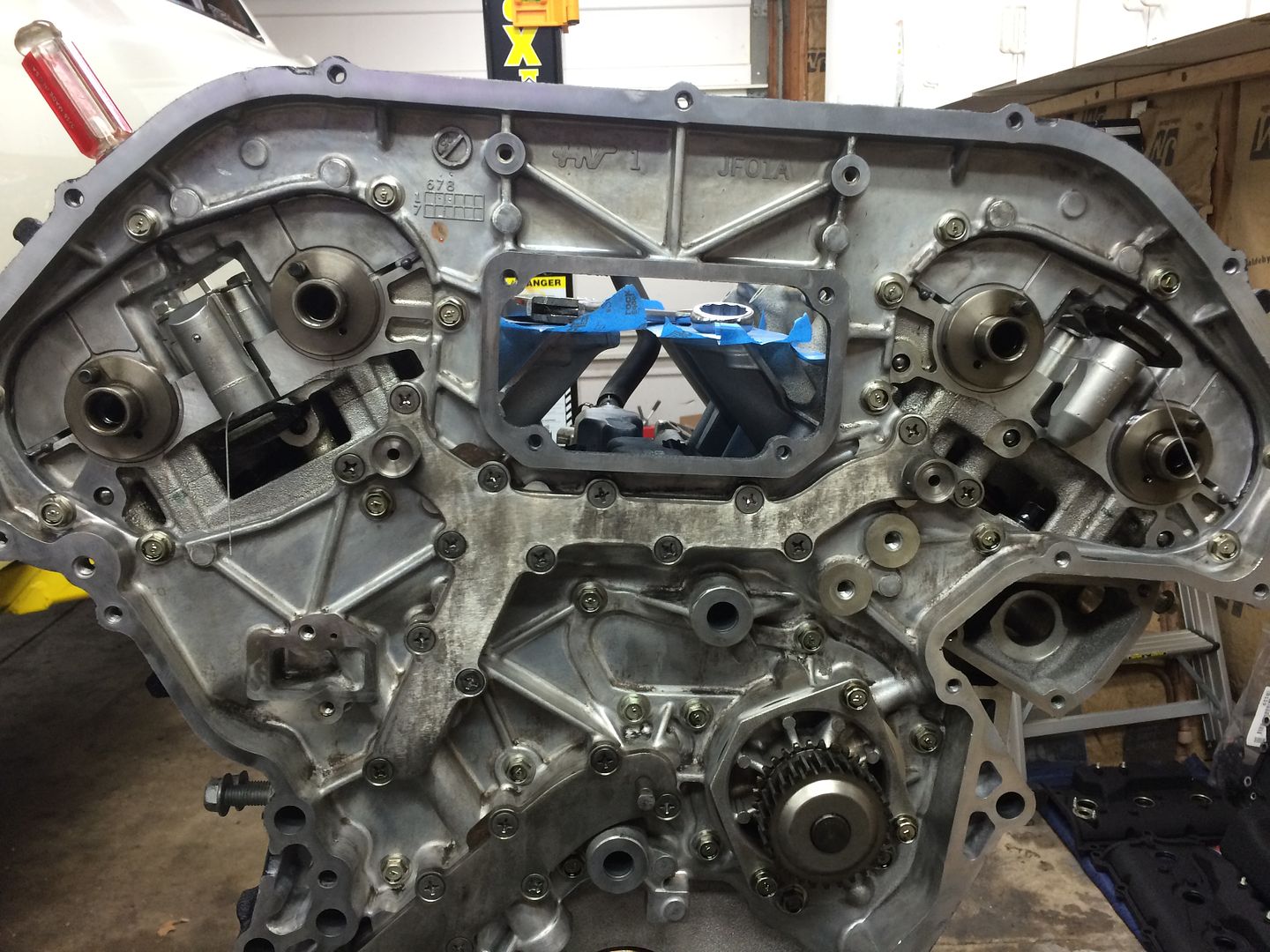

Now here we have the lower block assembly which acts as the girdle

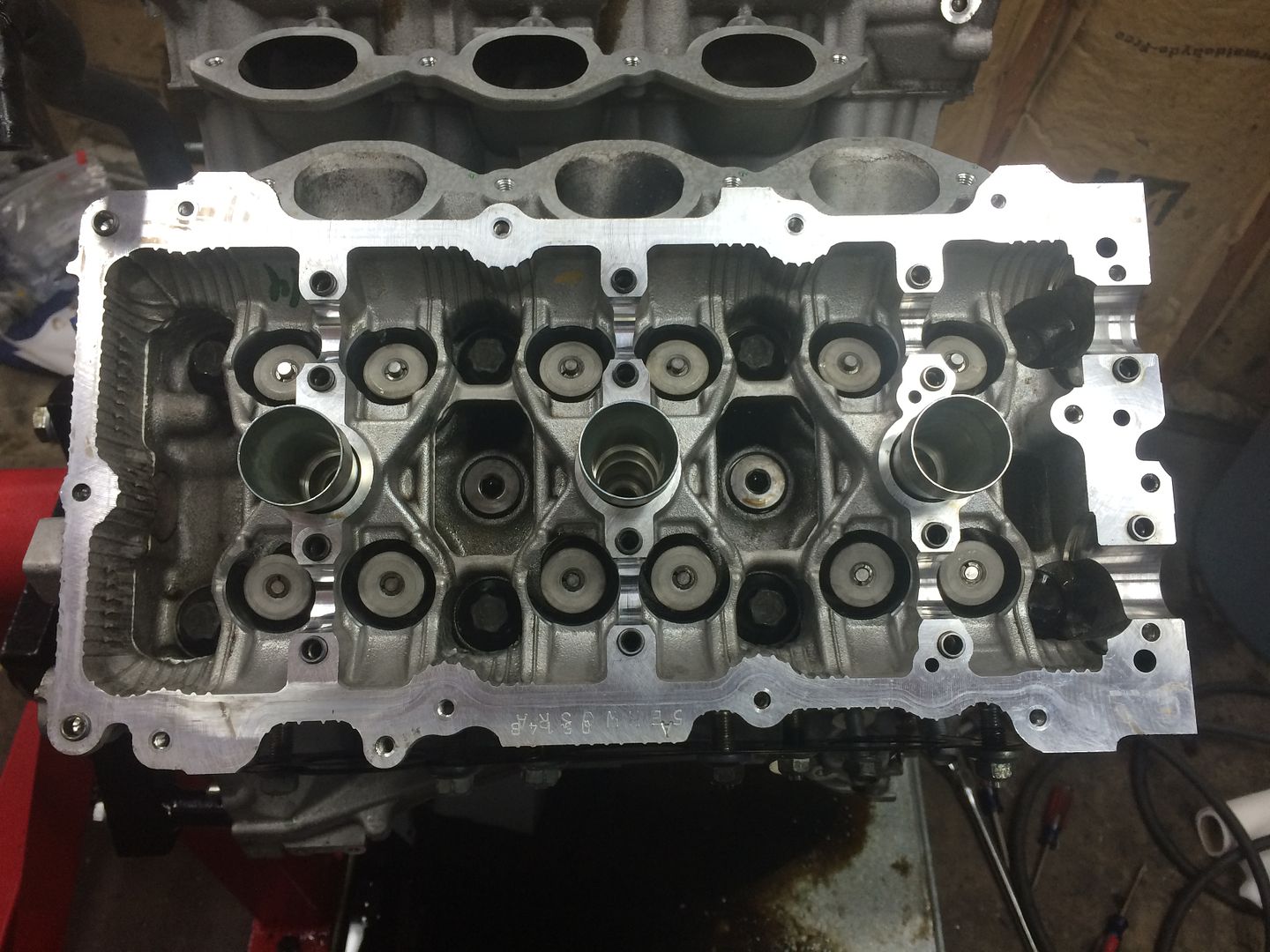

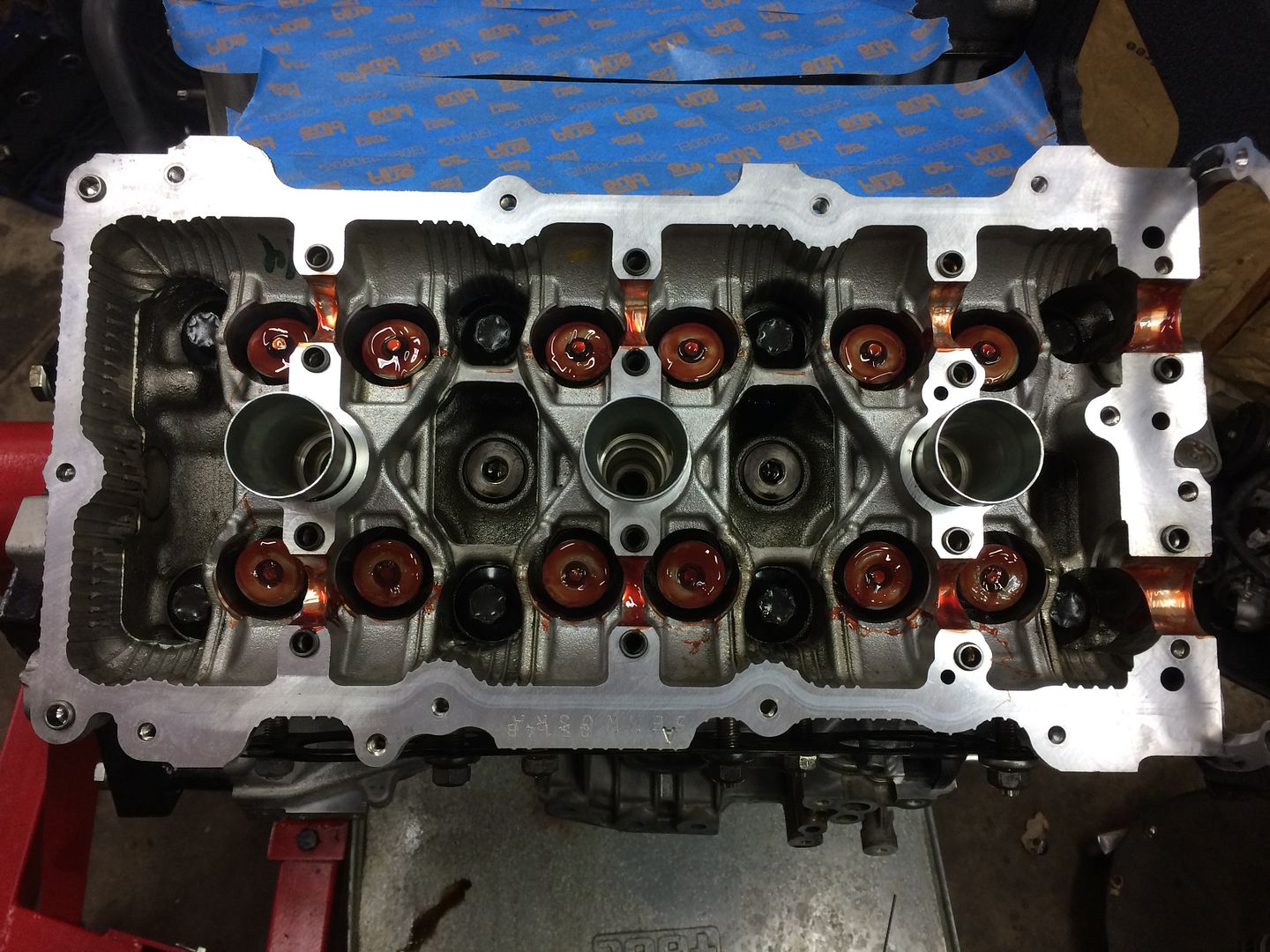

I spent some time cleaning the heads up in preparation of taking them off

That water pump housing area looks familiar doesnt it?

Here's a whole mess of GTR parts

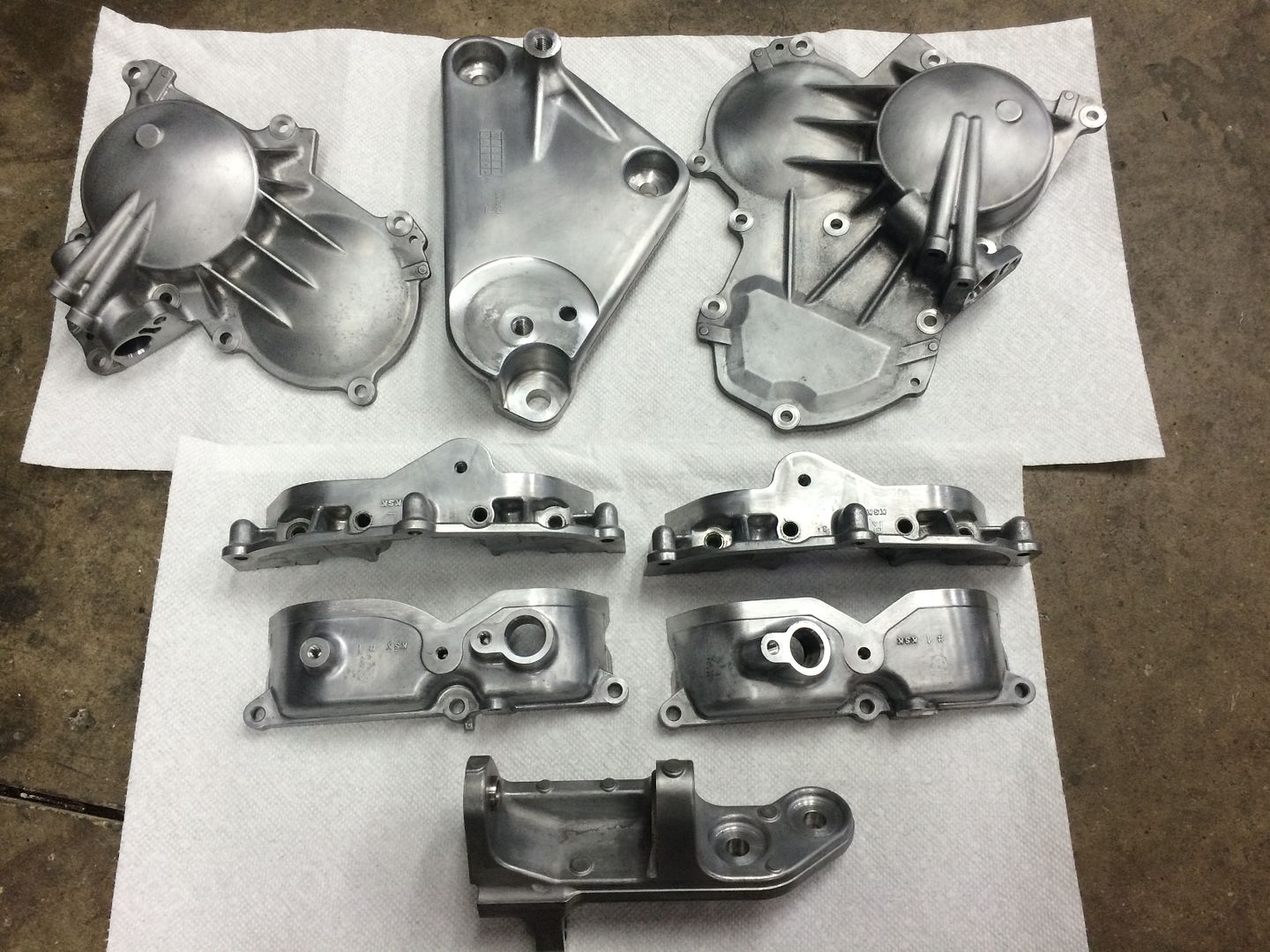

Cleaned up

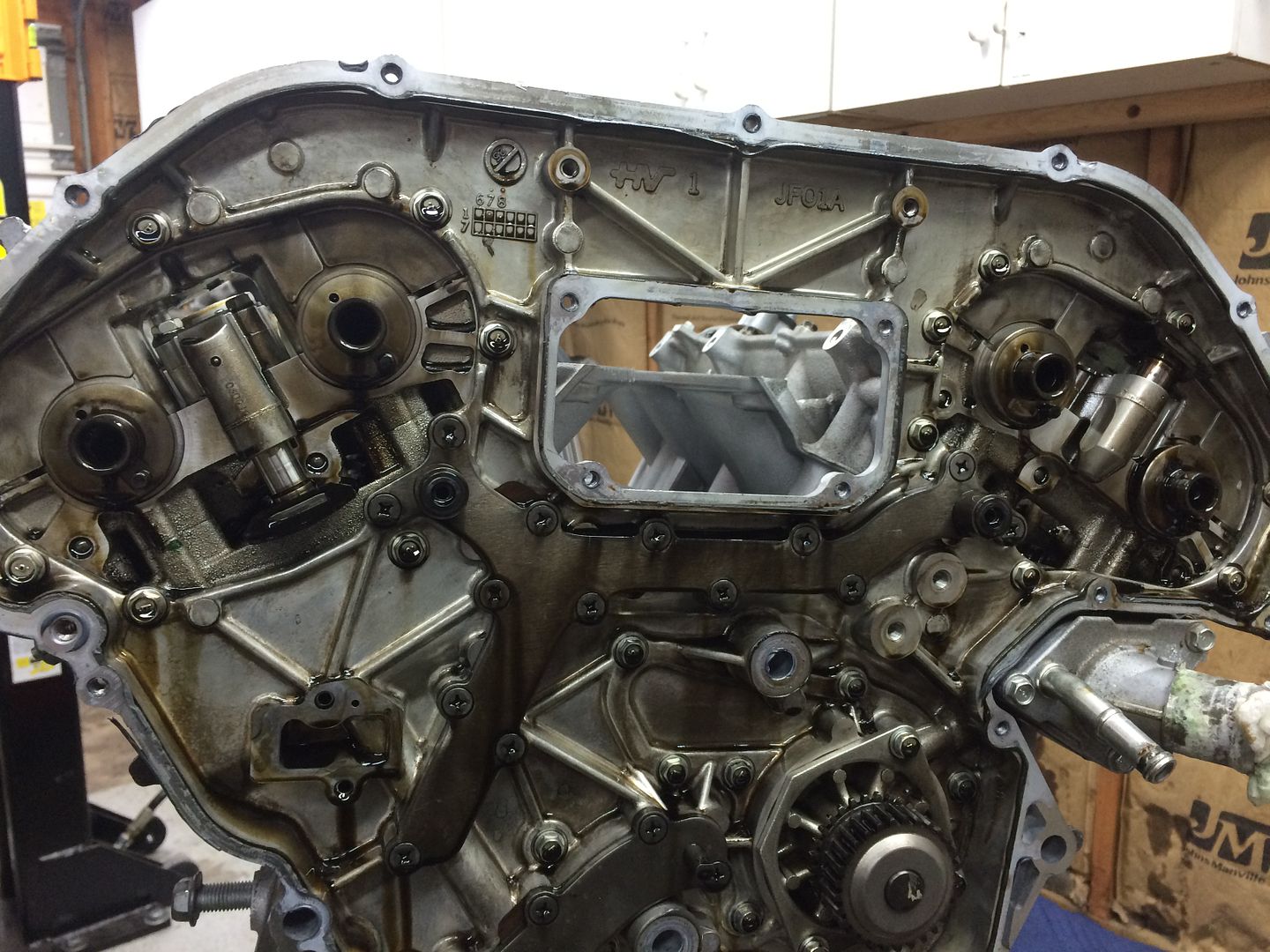

Here's the back of the primary timing chain cover...you have to clean the entire thing to get all of the RTV off of it....

Here is the rear timing chain cover....notice all of the provisions for oil and cooling circuits

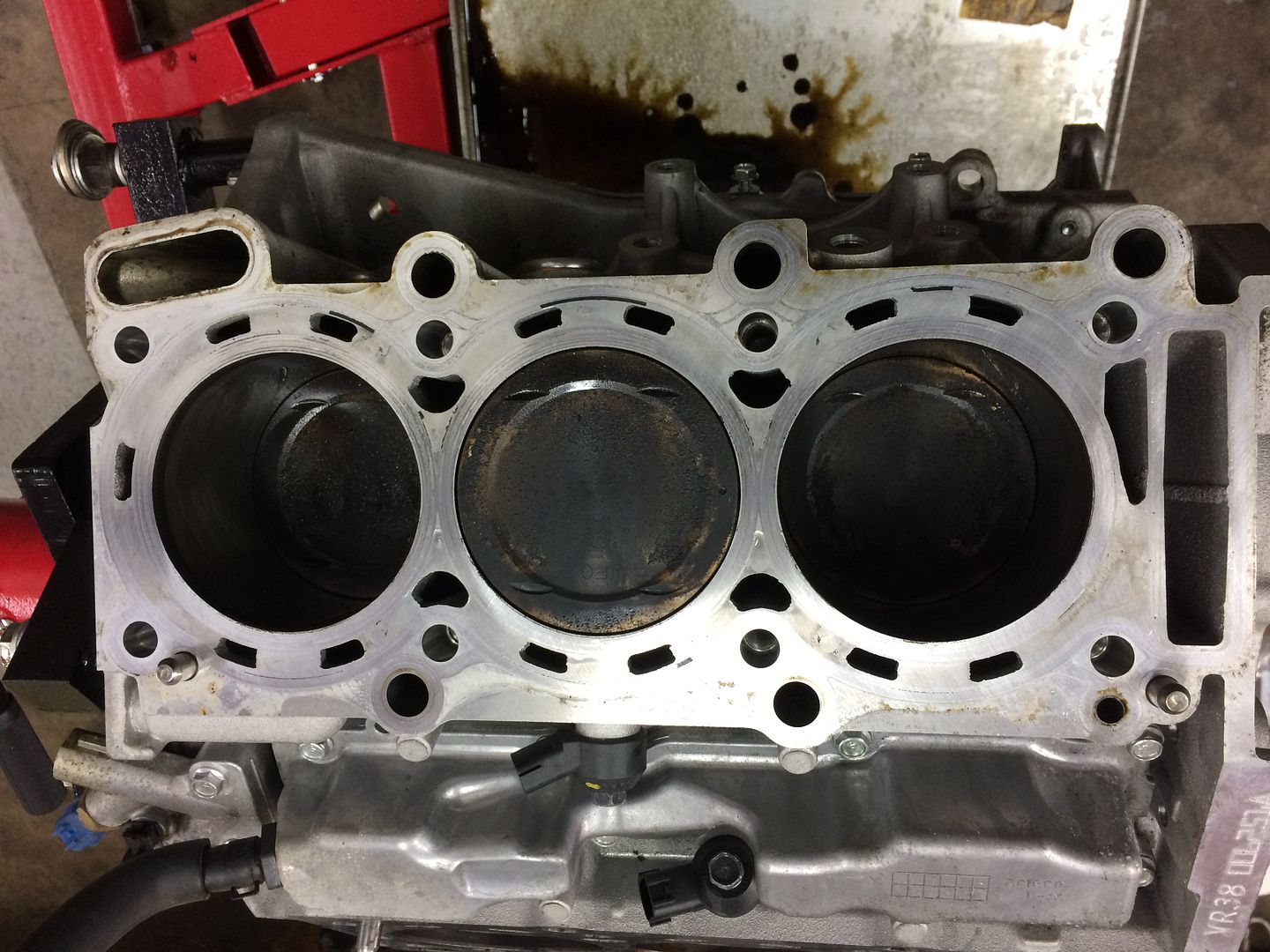

Next I removed the cylinder heads to gain access to the pistons

After that I popped the girdle off to gain access to the rods and crank

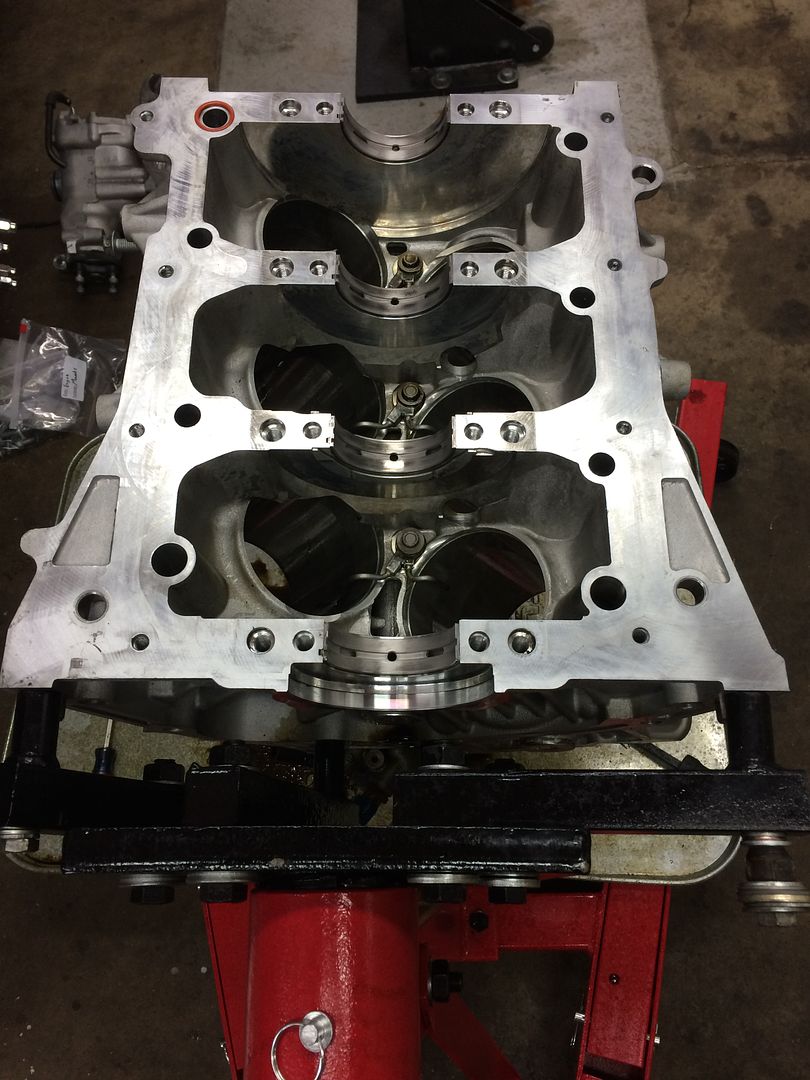

Pistons removed

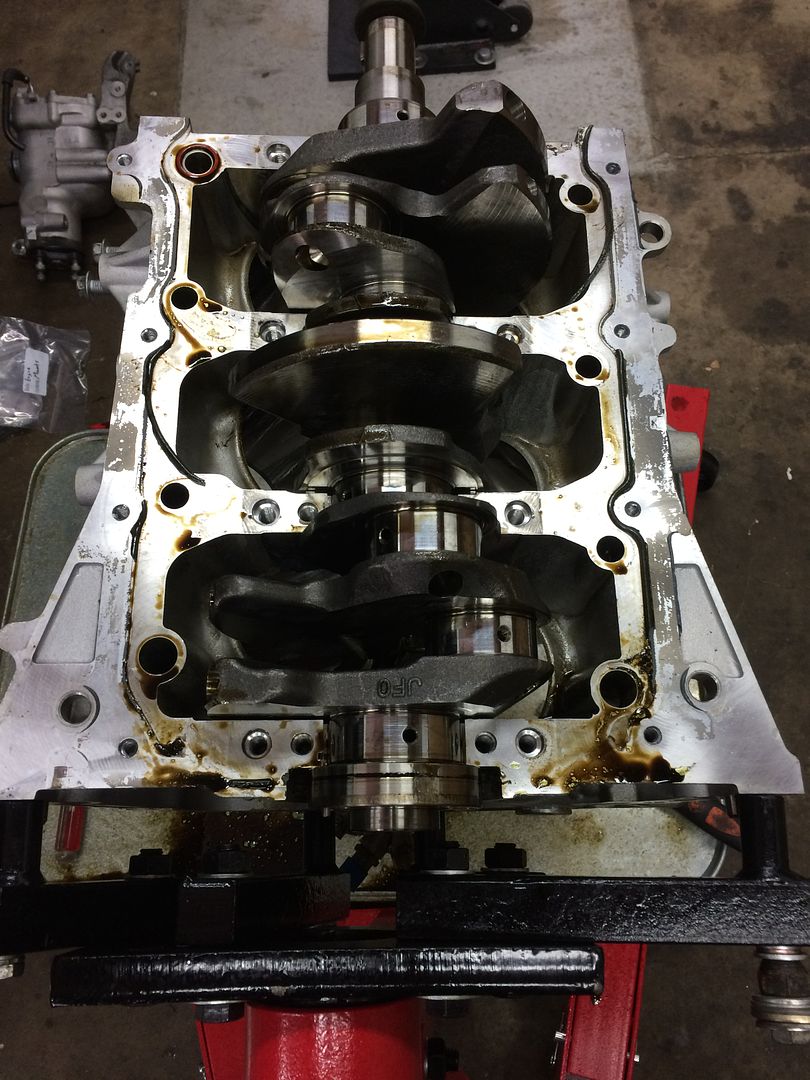

Crank removed

Bare block assembly

Grade stampings on the crank

Next I took the whole rotating assembly off to the machine shop to get balanced

Here's a better picture of the primary oil pan. Notice it has the pass through for the transfer case and drive-shaft, very similar to the older GTR setups

Girdle cleaned and new bearings in

While the assembly was at the machine shop I had some downtime so I decided to start cleaning things

Much nicer

New OEM gasket rebuild kit

New head and main bolts

Here I am laying out the pistons and rods for assembly

The pistons come like this, pretty cool touch

Rotating assembly ready to go

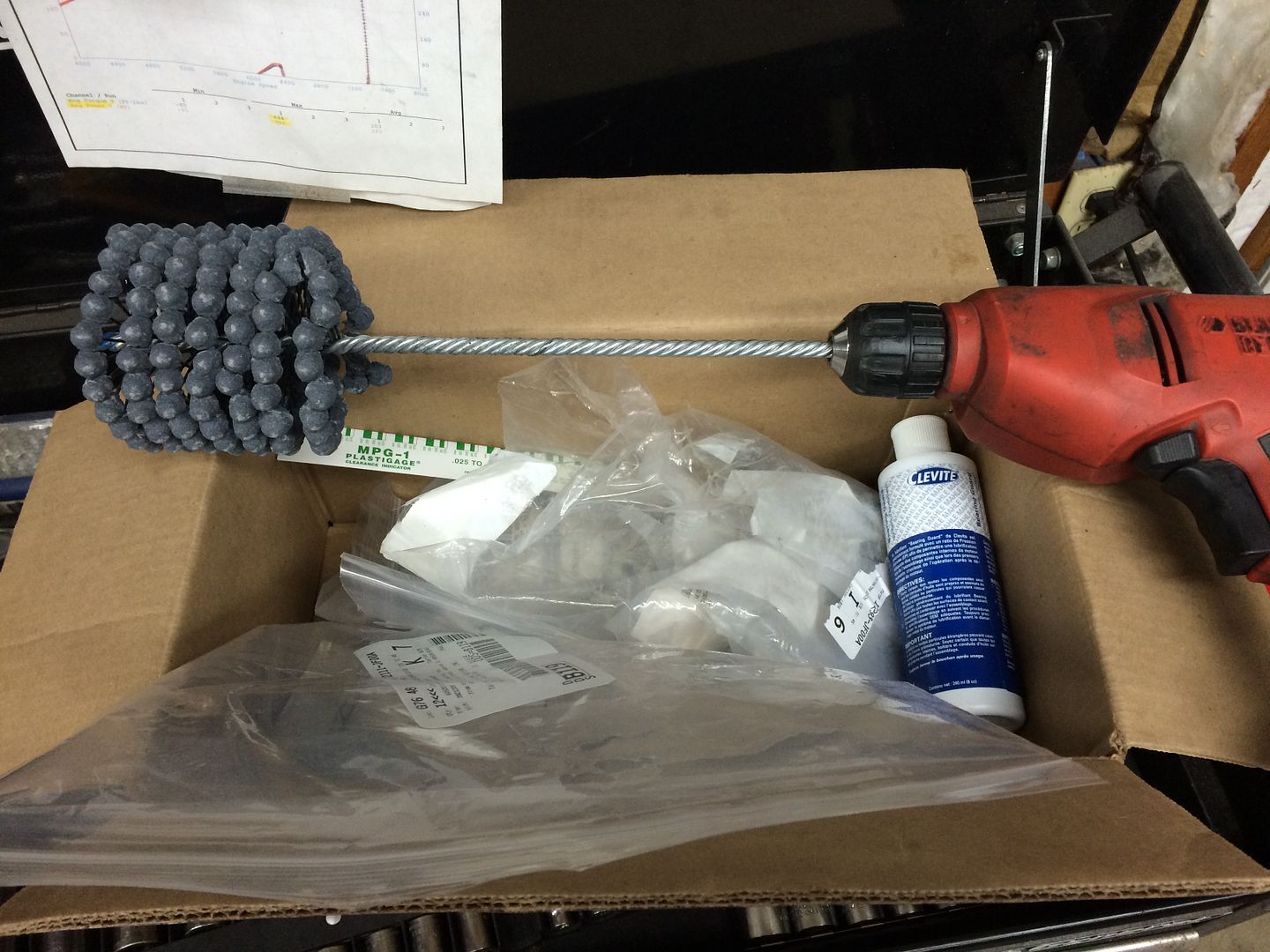

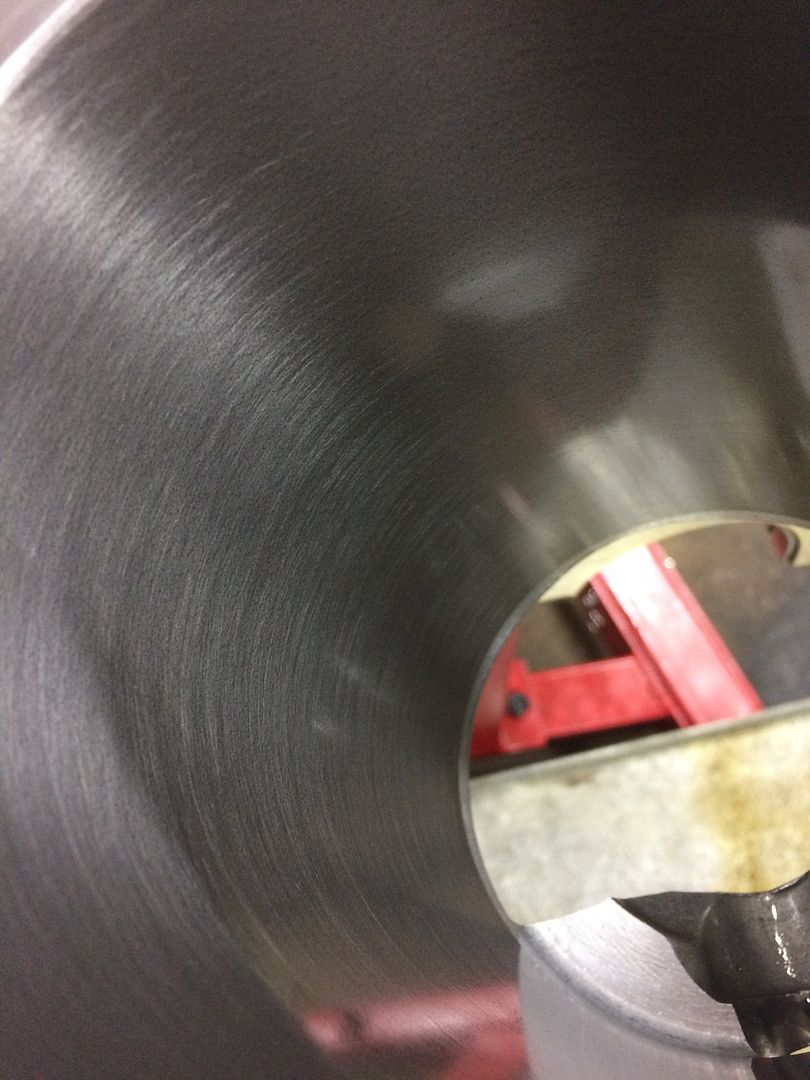

Next I used a ball hone tool to clean up my cylinder walls and add a little crosshatch to help seat the rings

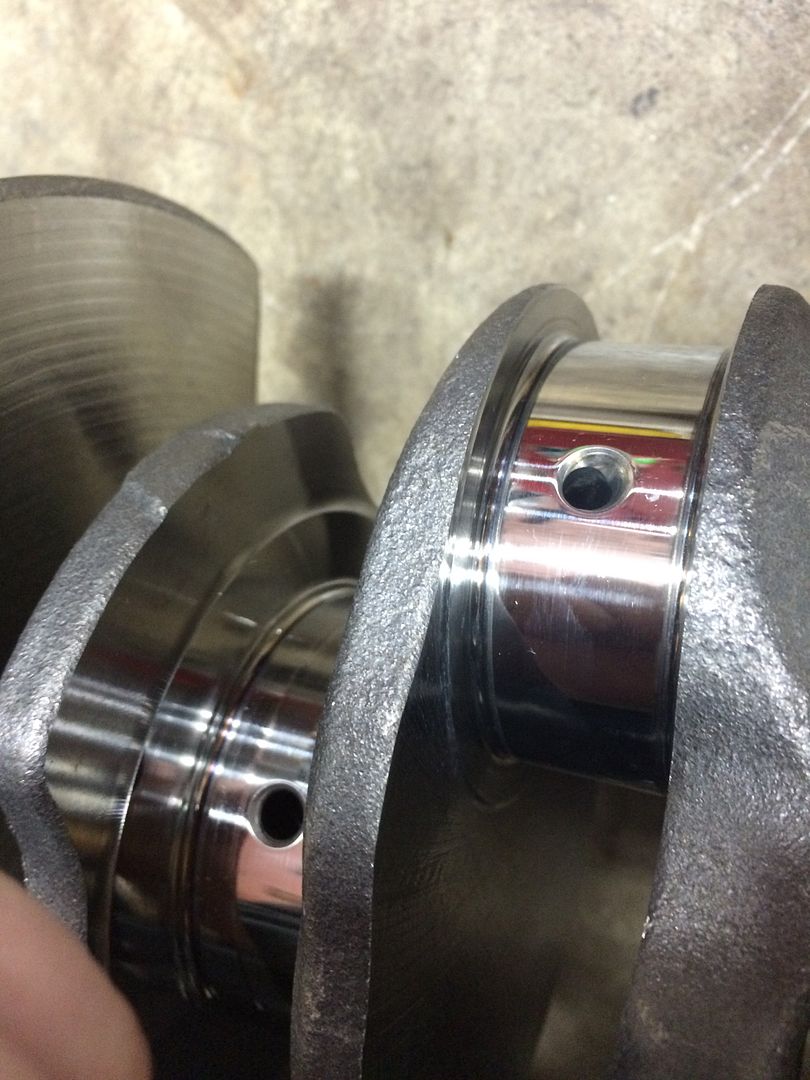

Nice finish on the crank

I used WD40 to act as a lubricant on the ball hone tool so you must thoroughly clean the cylidner walls until your cloth comes out spotless

Piston oil squirters look familiar

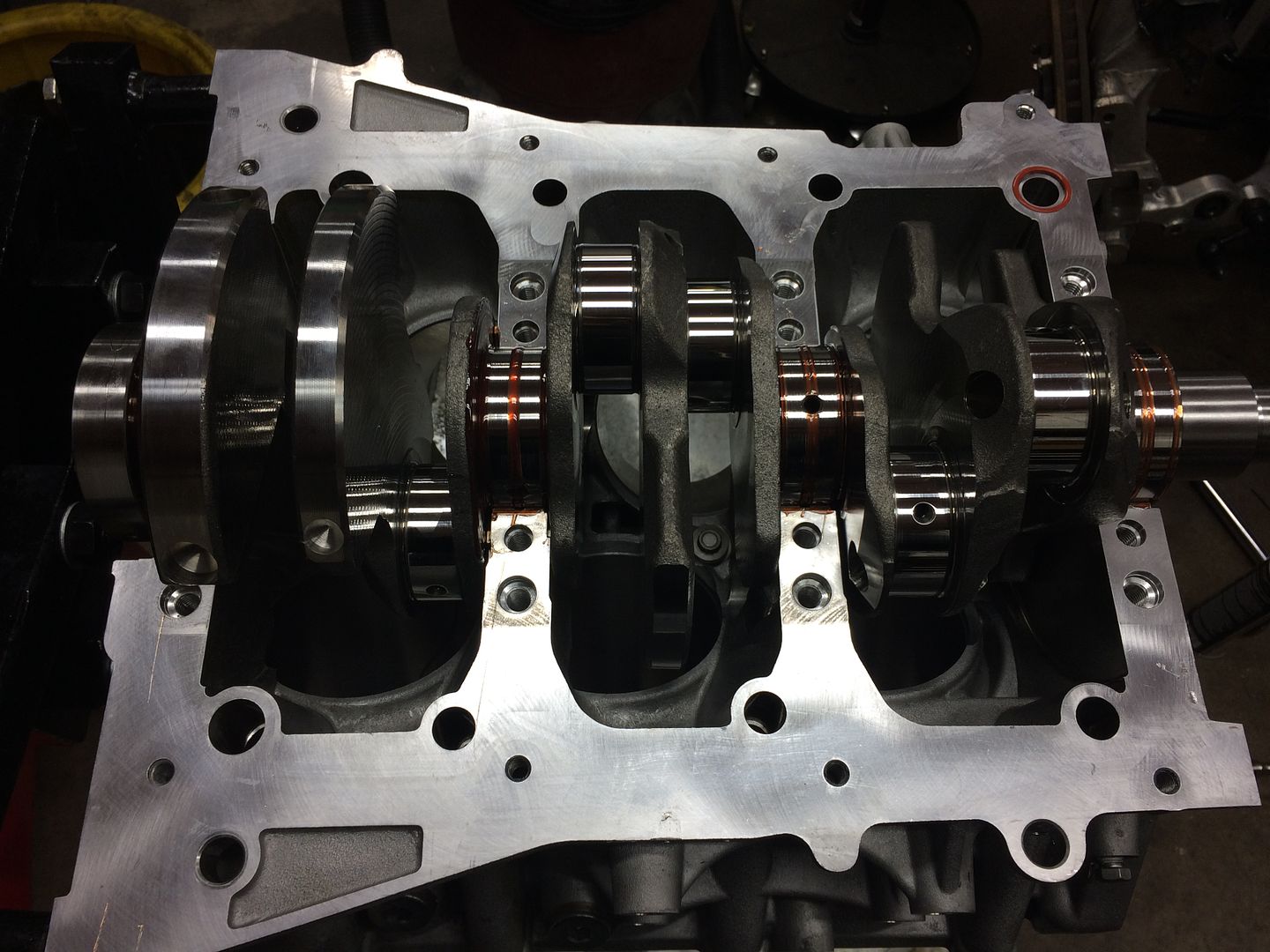

Set the crank in and spin it over a few times

Girdle ready to go

Girdle back on and torqued

Pistons and rods installed

The primary pan assembly also uses RTV to seal itself

I used long studs as guide pins to set the pan on correctly without damaging the fresh RTV

New OEM head gaskets

Cylinder heads back on

Now here's where I deviated a little and got crazy with the amount of time I put into this build. I wanted my engine to look top notch and like it was done by the pros. I ended up coating everything that was visible with VHT wrinkle black. Next to a wrinkle powercoat - I cannot tell the difference (and with close to 1000 miles on the car now the coat has not faded, chipped, or cracked) Here I am taping the rear timing cover off for prep

Primed

Coated

To get the coating to wrinkle, you have to hit it with a heat gun up to around 160-170F. It turns out awesome

Finished product

Same process for the front timing cover

Drying

Notice all the RTV that goes back on

Rear timing cover installed

Next up for the fun parts is the turbos. I went with a stock manifold turbo (notice how its integrated into the turbine housing) I expect above 8xxwhp and have seen several dynos with supporting mods make above 950whp with these identical turbos

Now back to getting stuff painted.

Now getting the cams back in

Cams and covers on

Now I can begin re-assembling the valve train

Timing marks

All installed

Again, with the crazy amount of RTV!!!!!

Front of the engine back together

Valve covers on

Now the engine is ready to come back off the stand and begin with the accessories and turbos

Bell housing back on

Also coated my 3" turbo inlets

Turbos and inlets are on

Test rig I setup to balance the wastegates

Getting back to painting the manifold

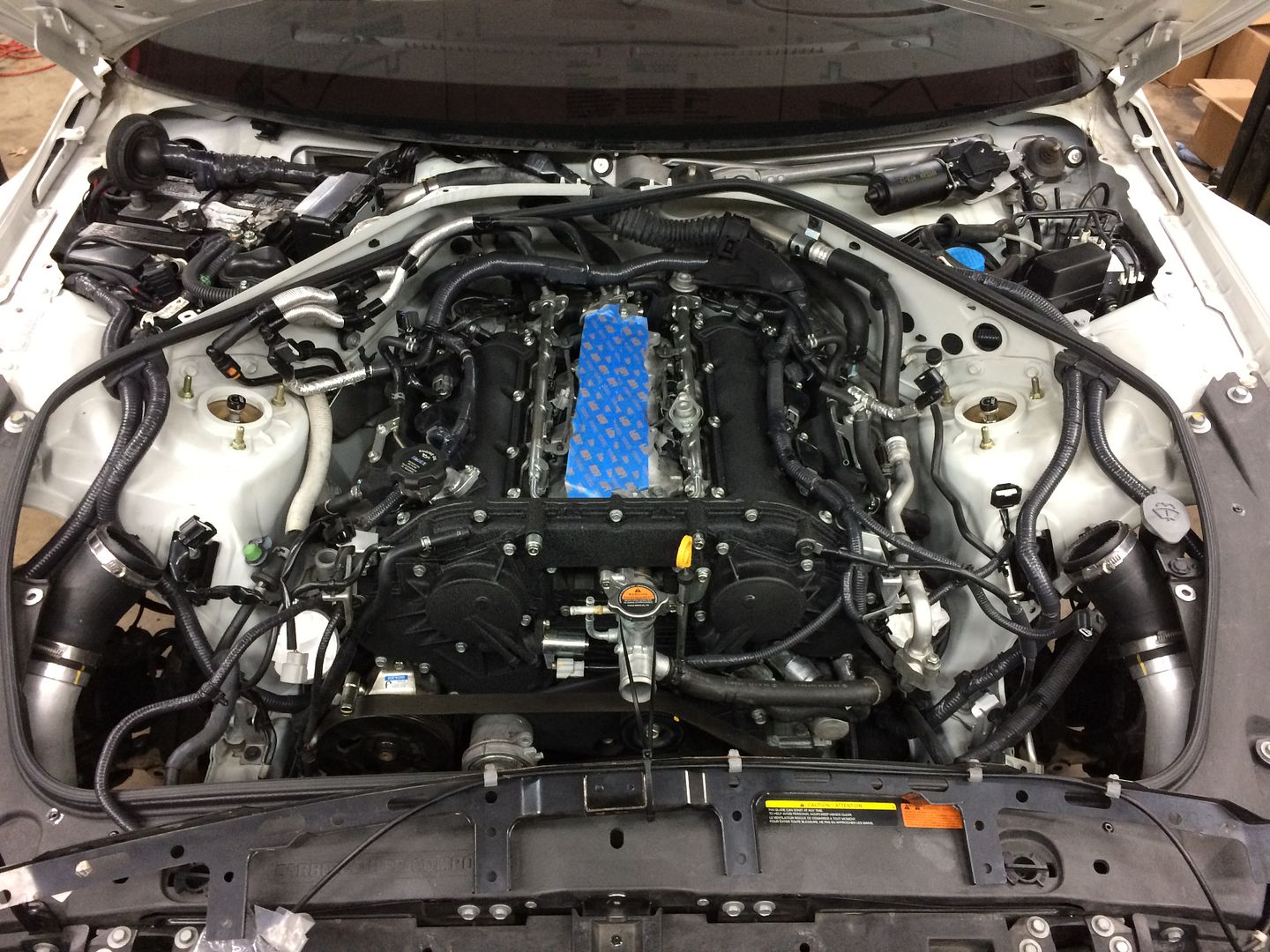

The engine is ready to go back in the car

I used the same slinger to bring it back into place

TB's mounted back up to the manifold

Exhaust back on

Here's a picture of my setrab oil cooler setup

Coated the IC piping as well

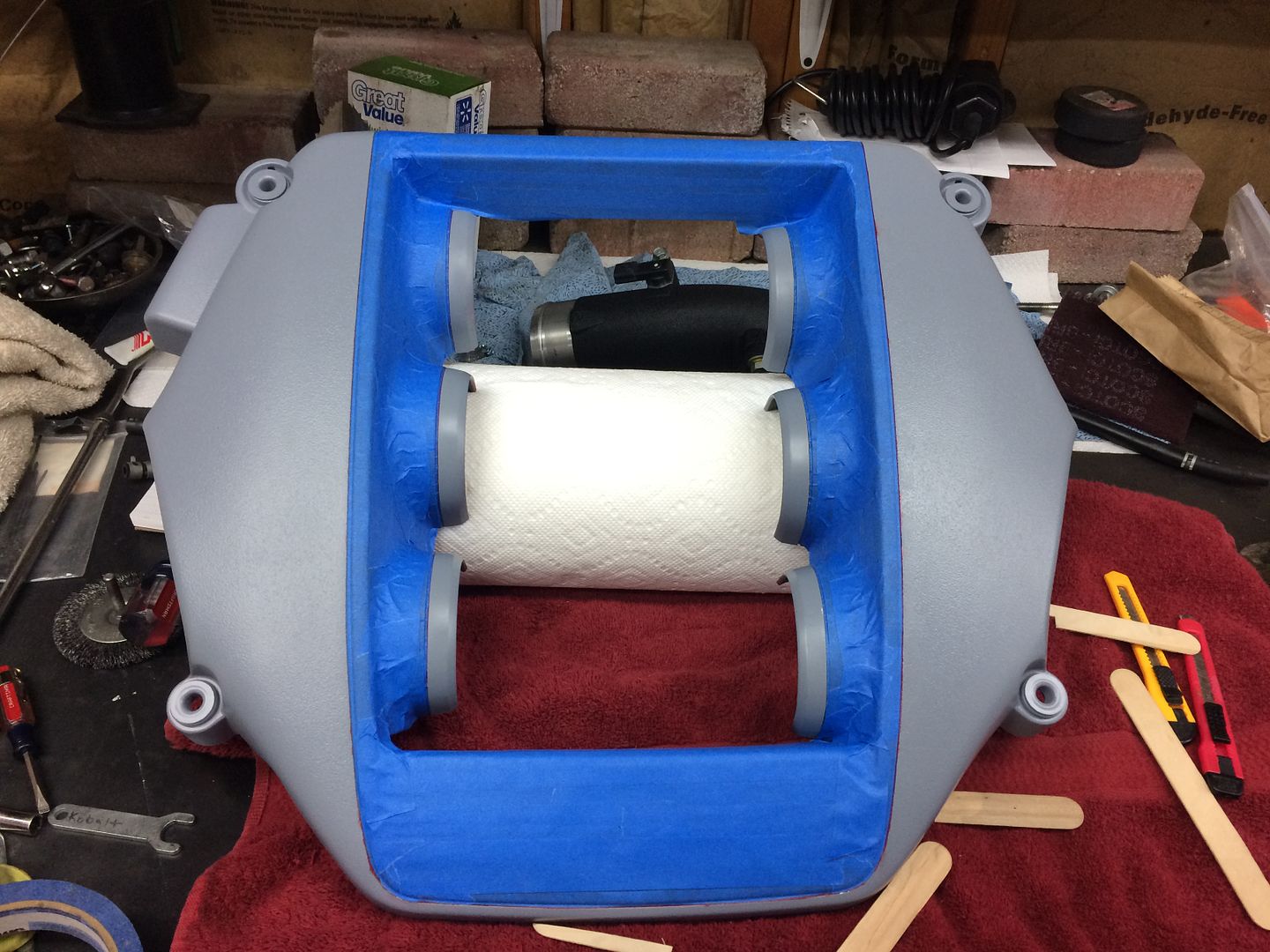

This next one, was a real PITA. I wanted this to look amazing though so I took my time on it

Masked off

I a custom paint mixed up from my local company. The color matches the "R" emblem in GTR

Masked it back off to do the wrinkle finish

Completed

I also coated the expansion tank

After that I got all the accessories fastened back up and thought, damn it is really looking good

So I figured it was time to fire it up!

Then I needed to commission the car before taking it on its maiden voyage

This is me, the man behind all the madness

After putting some break in miles on it, I pulled the oil out and cut the filter open. So far it is looking good

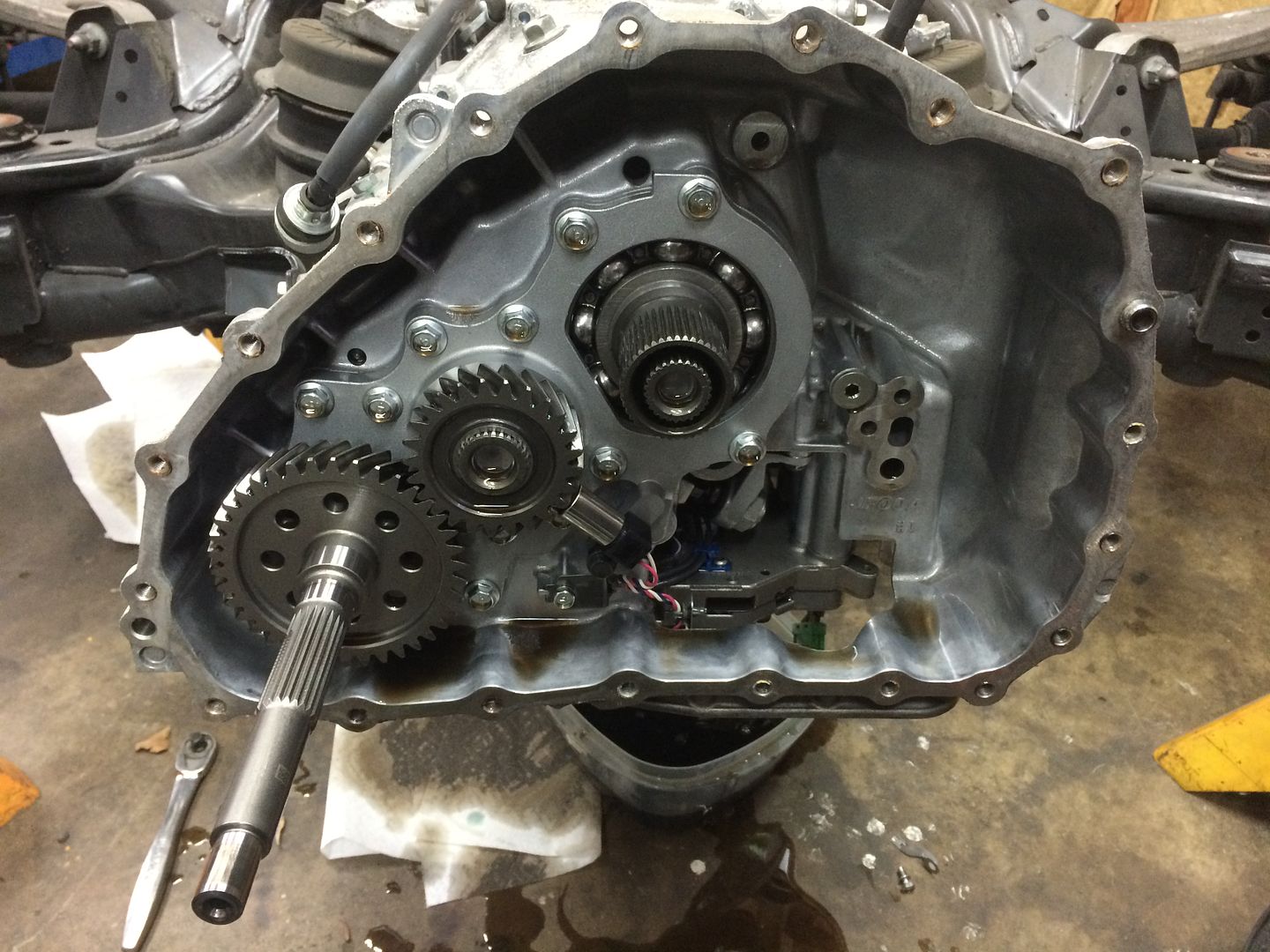

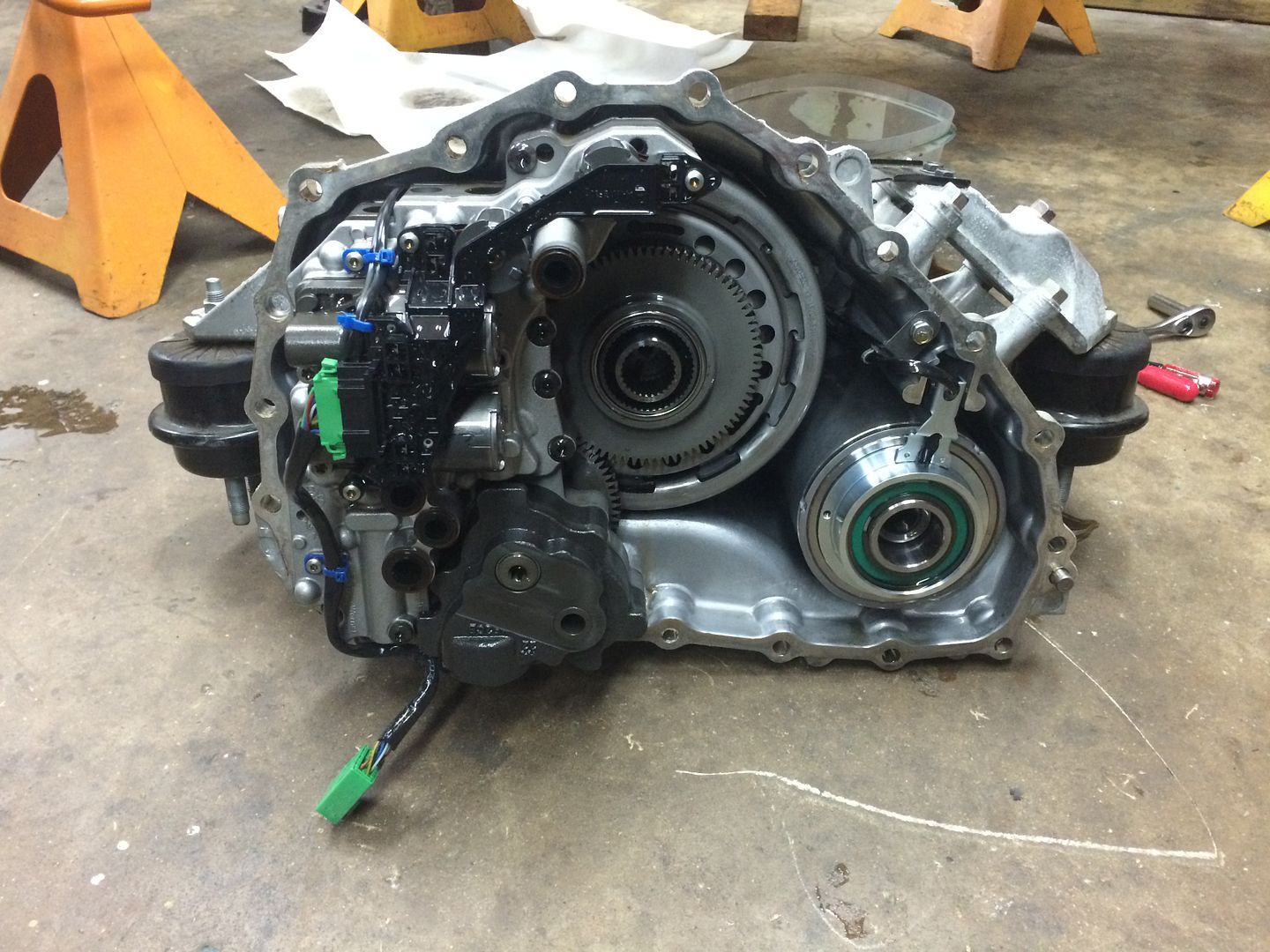

So since the engine portion of the car is going well, and my power expectations exceed that of the factory transmission - I decided to pull that as well and do some upgrades

Pulled the trans pan

Now I need to pull the front case

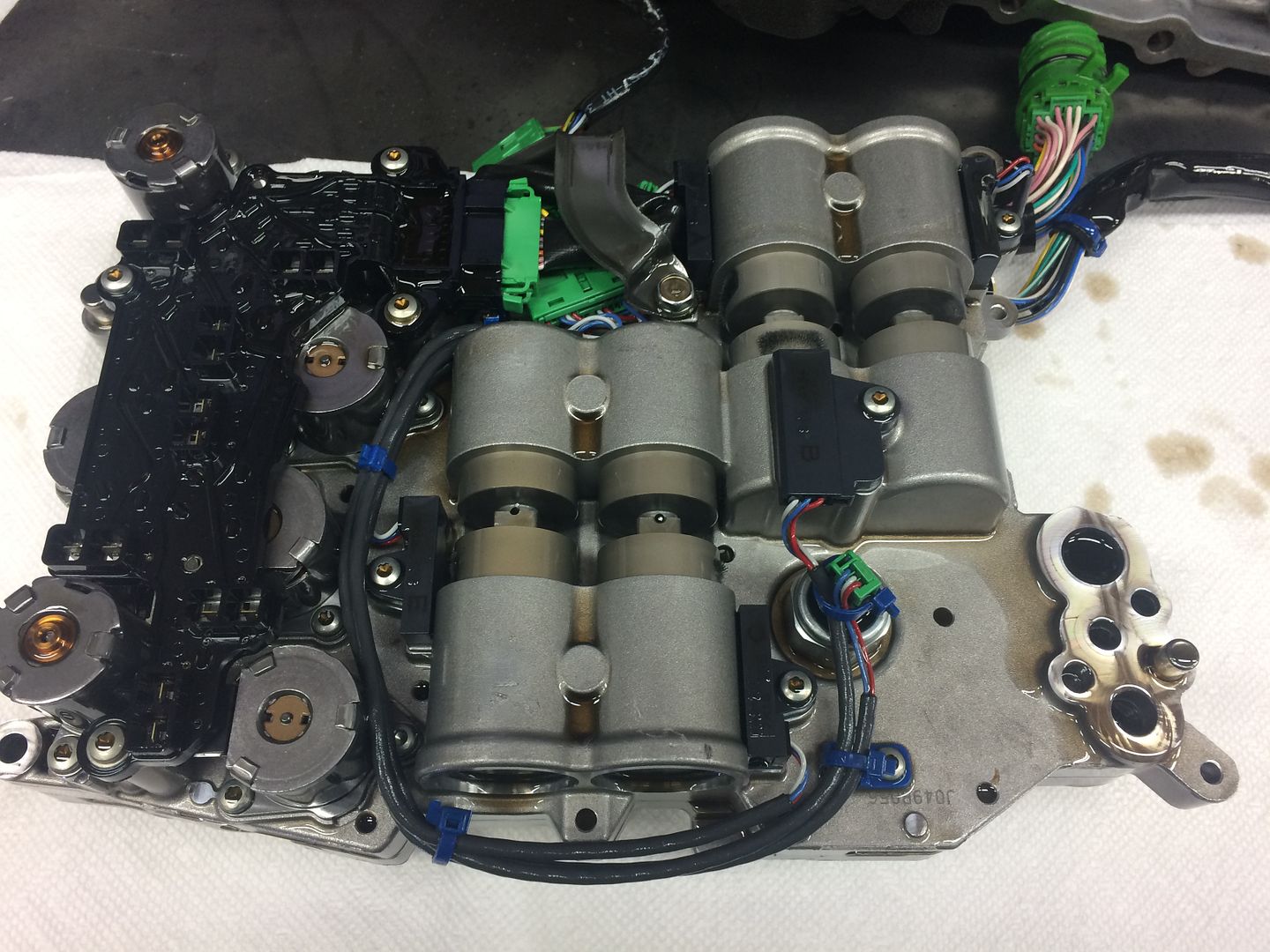

The case contains the factory clutch packs and valve bodies

I removed the valve body to get the clutches out. These are what will begin to slip, much like a worn 5spd trans/clutch setup would

Clutch packs out

New clutch pack setup rated for 800ft/lbs

Going back together

Then I pulled the trans valve body to do some updates the factory recalled

Clips installed

Here's the trans minus the valve body. You can see the gearset

Front case re-installed

Trans going back in - its a girthy bastard

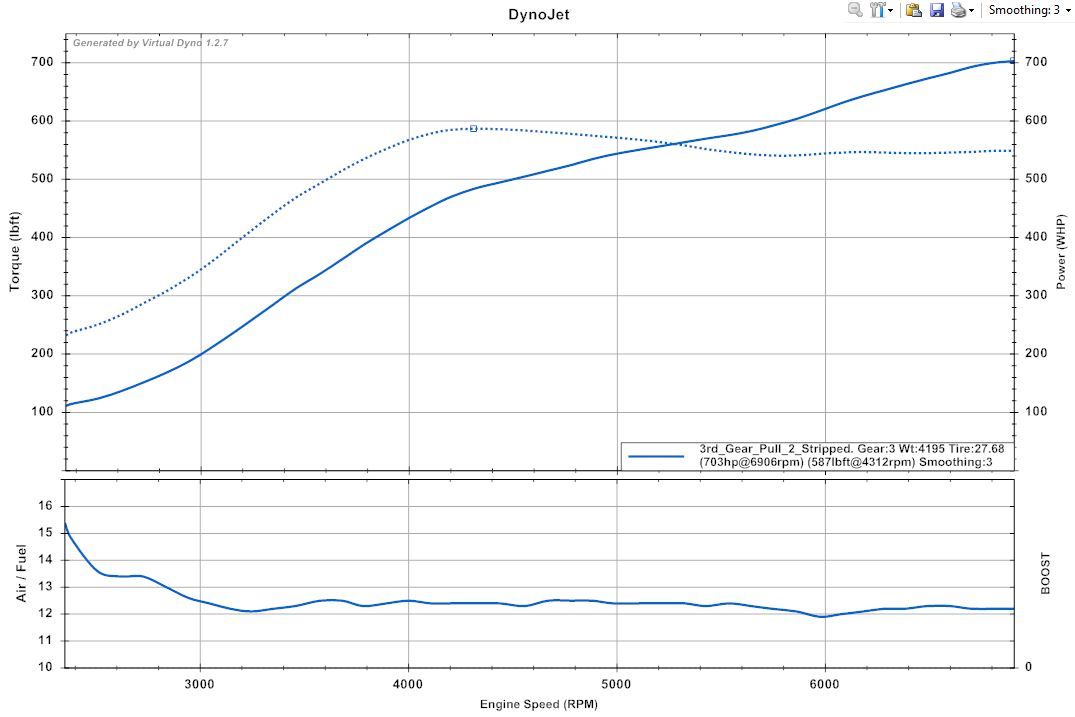

After that I got the car back out on the road and did some tuning and tweaking. This is on a very MILD setup on 93 octane.

After that I decided this thing is going to boil the tires off if I take it to the track so I added some rear wheels/tires that will shave a good 30lbs of unsprung weight off the car

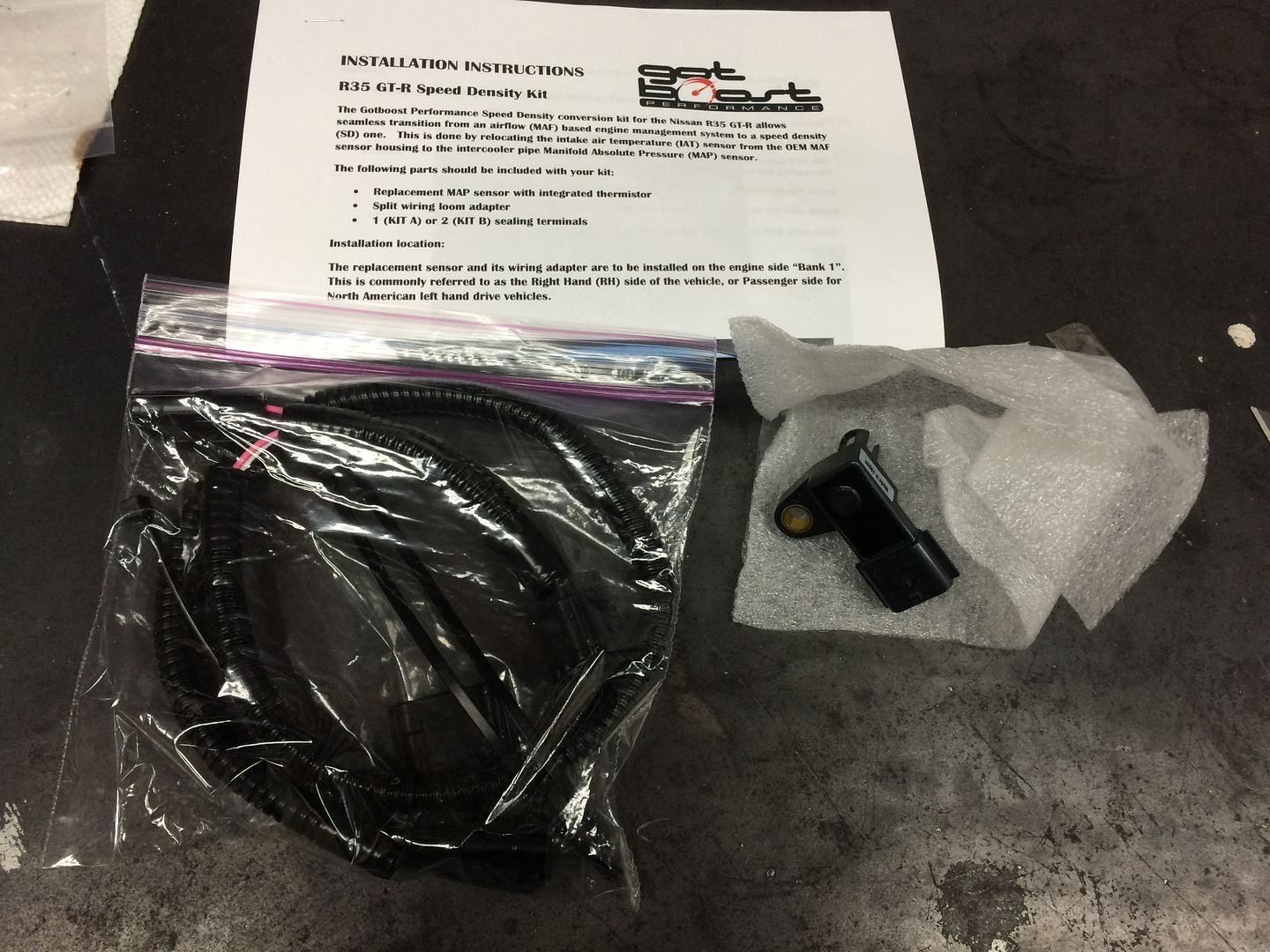

With this kind of power I'm going to be knocking the MAF system out of the park with readings so I've converted it over to speed density. Simultaneously, I converted the car over with a flex fuel kit that will automatically read ethanol content and pipe it into the ECU. The ECU will make adjustments on the fly so no matter what fuel I have in the car, I will have maximum HP on tap

I also needed to do some fuel system upgrades so after verifying the car ran great on the previous setup, I installed some ID2000's

The pumps also need to be addressed, and I have a good setup on order but I wanted to go ahead and supply them with GOOD power so I put together this hardwire kit

Each pump now has its own dedicated relay and a good power supply. Factory functionality (the GTR has two pumps from the factor) is maintained

Wow, what a read so far right? Well there's more........Back when I first got my Z I did not like the red interior so I slowly converted it over to black interior. I'm biting the bullet and doing it all now on the GTR. Mine came with ivory interior which I can't stand and it shows dirt really easily. I began converting it over to black interior This process starts with pulling the seats

Completely stripped them down

Next I wrapped my center console and steering wheel trim in Di-Noc because the factory finish scratches very easily

For the front seats, I am having interior-innovations do a custom seat skin which will be a very classic nova-suede and napa leather design in all black. They are supposed to be done next week and I can't wait to get them back I'm going to address the rear seats on my own. I have dye'd seats previously with really good success so I had my local paint shop make a custom matte black color with additional flattener

I made my own spray booth

Simultaneously, I wanted to safen the car up a bit so I bit the bullet on a bolt-in roll bar. The only problem was this blocks access to the rear seat. I take my daughter every chance I get so she needs to be able to get in and out of her car seat. This meant I needed to modify the roll bar I cut the roll bar harness section out and added these bar clamps

Now the bar is removable at the harness section, making access much easier

So after dying the seats I re-painted the roll bar after modification

Seats are done

While all of the interior was out, I wanted to really give it a nice touch so Khalid hooked me up with some more novasued and I removed the headliner

Now its suede!

The rear setup is finally all installed

This brings me to this week.....I decided to do a little audio mods

Pulling out the factory subs

New L7 installed

The only thing I'm waiting on now is the seat covers and the car will be ready to rock and roll! I hope you guys have enjoyed this journey as much as I have!

TR%202/GTR_Signature_zpsbfc89d27.jpg> TR%202/GTR_Signature_zpsbfc89d27.jpg>

|