I was contacted recently by a TT.net member see if I would be interested in trading a set of my motor mounts

for these copies; I tried to do this when AMS first released these in December 2010 but AMS wouldn't sell any

while the debacle was unfolding. Here it is almost a year later and I finally get to see what AMS' puppet

company [Z32 Innovations (how ironic)] is offering to the Z32 community. So what I have here is a random

example of what AMS/Z32 Innovations feels is of high enough quality to ship to one of their customers.As the originator of this motor mount design, you might guess I'm not going to have anything good to say

about a copy of my product - so let's get the one and only compliment out of the way: I will say that whoever

it was that copied them in Tiawan or China did a good job of duplicating the dimensions to the tee, the rest

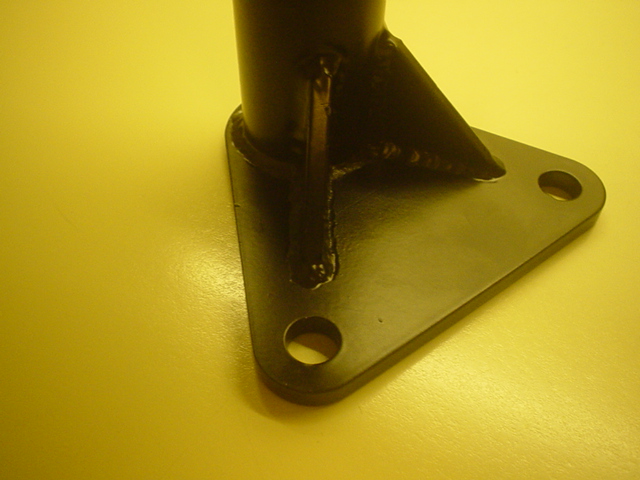

though... well, see for yourself. Supposedly they are TIG welded and I agree these are TIG welds but definitely in the hands of an amateur.

Here's a weld gone awry, it actually blew through the other side. Oh well, powder coat it an no one will know.

Keep in mind this is a random sample, there could be worse.

More TIG welds only this time with serious under-cutting of the base material and little if any filler rod...

these are potential stress risers and sources for eventual cracks.

Hmmm... what's this? It looks like a pressed in pin.

Yep, that's the pin that locates the mounts in the chassis and it is pressed in. These take a beating when

positioning the engine, it would be easy to knock one of these out.

BDE pin for reference, it's all a one-piece billet, you can see the milling marks that formed the button. More

expensive to make? Absolutely, but it's the right way to make them - I simply will not compromise on quality.

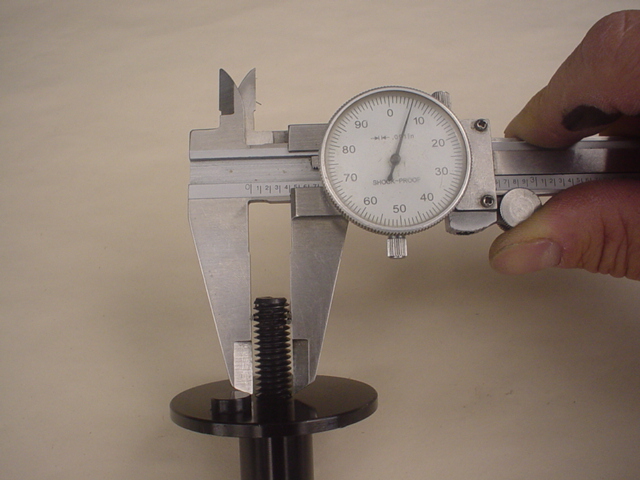

Here, the AMS/Z32 Innovations threaded stud is measured with gauge pins. This is supposed to be a 10mm

fastener but it's closer to 9mm. This is a critical fastener - oh well, loctite it in place an no one will ever know.

BDE threaded stud with the same gauge pins, easily 0.030" larger in diameter and most importantly... a true 10mm stud.  There are many other differences, like the bushings are some unknown rubber vs true polyurethane as I use

and all the fasteners are of typical China quality vs my use of stainless and ARP fasteners, but these

examples are by far the worst. Being that this is TT.net, I know I'm preaching to the choir, but I've been wanting to do this for some time

so people who do not understand what the phrase "you get what you pay for" means can see what a cheap

immitation is - unfortunately, in this instance of cheap motor mounts, you'll never get what you pay for,

no matter what the price may be. True garbage in every sense of the word.

|