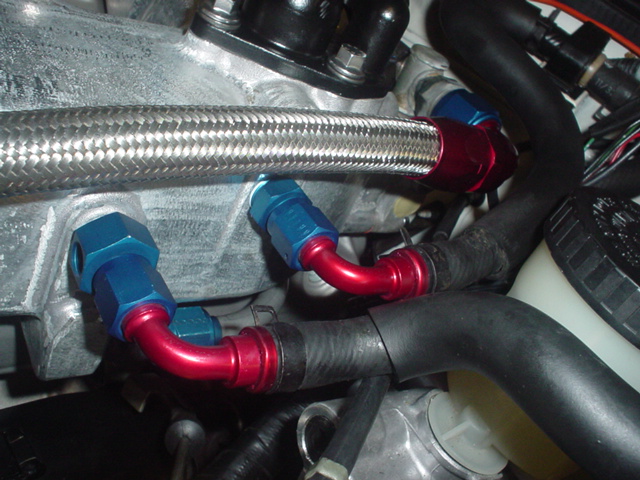

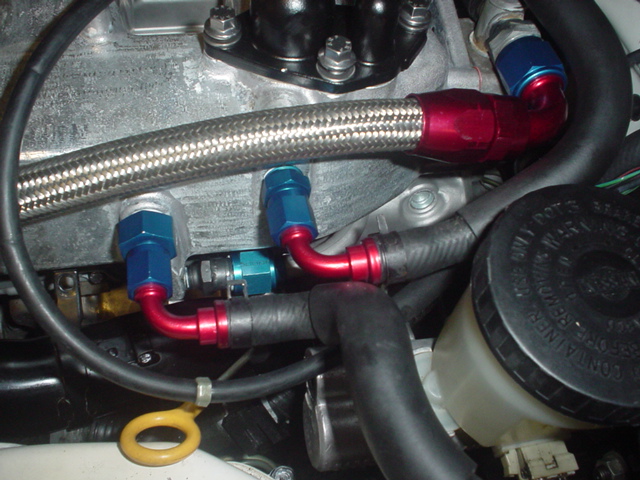

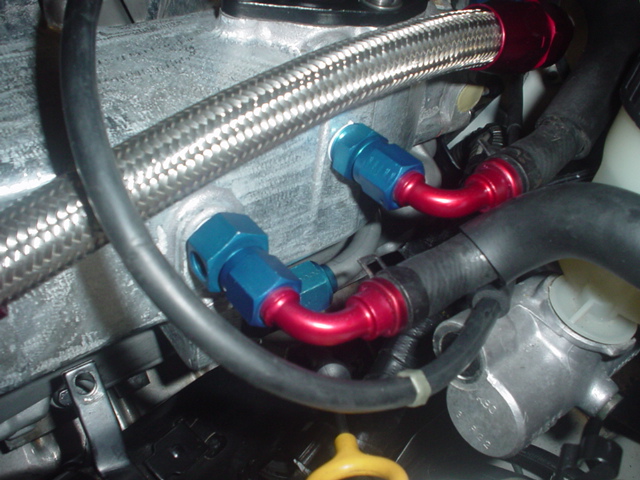

| I'm currently doing a top-feed fuel rail conversion on my Z that I picked up last year and I got sidetracked with some minor annoyances under the hood... Goodbye stupid looking stock idle air valve pipe and hoses, hello -10 AN fittings and hose. I TIG welded the -10 AN adapters to the stock parts (this was a major PITA).

The stock spigot for the brake booster was a bit too high and in the way of the new idle air hose, so I plugged its port, drilled another below it for 3/8" NPT and added a -6 AN push-lock fitting to the stock hose - this worked like a charm. I couldn't stop there so I did the same to the clutch booster hose and got a special adapter fitting so I can run the boost reference hose to the recirc valve (had to drill and tap the stock port for 3/8" NPT).

Look closely and you can see the PCV valve converted to -8 AN.

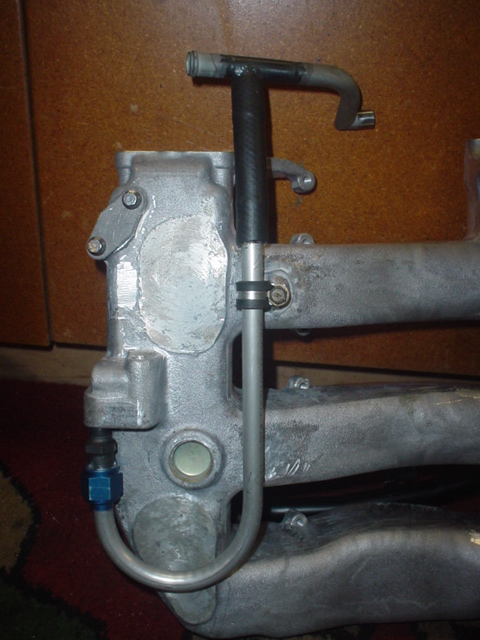

Here's the PCV rerouted into the tubes that come off the intake valve covers. I lengthened them about 1.250" and will shorten their hoses accordingly (keeping the stock restrictor installed). If I do this again, I'll probably ditch the hoses and weld -8 AN adapters to the tubes off the valve covers and connect the new PCV hard line with an AN nut; this will greatly simplify teardown and assembly.

That's 1/2" 6061 T6 tubing which comes in straight sections. It's harder to form than the annealed stuff found in coils, but I needed straight tube to work with a small mandrel bender that I made to do these bends - it's a work in progress but it did an ok job for the first time through.

Here's the PCV valve converted to -8 AN. I cut off the front section at the hex and welded a threaded section from a JIC hydraulic fitting, cut off its coned end and made a press-in aluminum cone to give the plunger something to seat against.

|