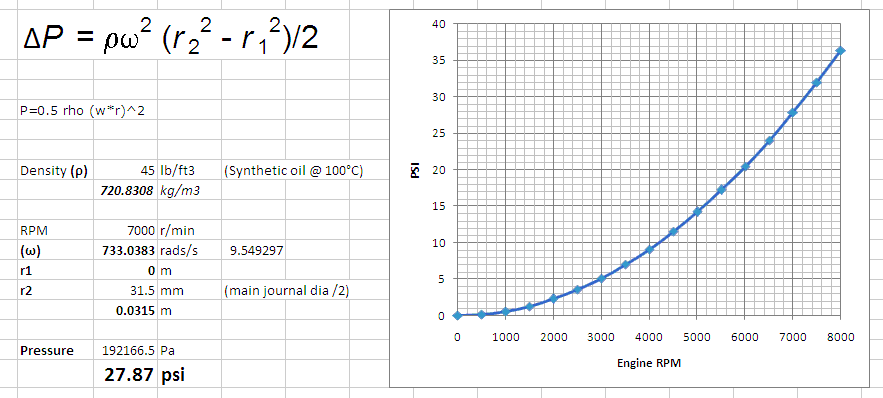

| encountered at the inlet due the cetripetal force on the column of oil. These numbers seem very significant... can you check my work independently? To reach any useful conclusions you would need to know the pressure drop accross the oiling system up to that point over a range of flow rates. We know the cranks are failing from fatigue because failure surfaces show beach marks indicating progressive failure from cyclic loading. Its concievable that centripetal backpressure could lead to bearing touchdown if the rod bearing pressure rose high enough. You'd have to cross the point where the pressure at the rod bearing oil inlet isn't enough to maintain the bearing oil film. The cyclic loading may also be simply from the HIGH peak torque everytime a cylinder fires. Its also very possible that the cyclic loading is coming from undamped harmonics as Aliaz suggests. I've seen beefy superalloy parts crumble like a cracker during "shakertable" vibration testing. I believe the risk posed from high energy vibration is underestimated by nearly everyone except those who specialize in this area. My gut tells me its it is either the direct loading or vibration but more data is needed before we can make any real conclusions.

www.selindesign.net

|