| Let me set the scene here everyone. All of my comments will be in red and I do step away from professionalism in several comments because Ash's perspective here is just plain silly and I felt poking a little humor at this would raise me from my pissy mood. I have included Ash's entire post but due to the lengthy girth of the original document all of Ash's pics are not included as I don't have a problem with his work as a photographer. However, I have included some of my own pictures to refute his claims where applicable. At the end of this I do offer a brief explanation of my understanding of VTC noise and the major contributors. Fade in... a distinct sound of someone tooting their own horn is heard somewhere over the horizon... I recently made a trip up to Minnesota to assemble Tyler Duschane's new TT he purchased. I built the engine for his old TTZ about 3 years ago - he disassembled the engine and had all of the parts machined to my specs by a machine shop local to him and I flew up, put the engine together, installed water injection, and then dyno tuned the car - breaking the engine in using the "Moto-Man" break-in method. The engine was equipped with Wiseco forged pistons and only basic portwork was done in the heads - as much as could be resonably accomplished using a dremel, which is a far cry from what one would want to have for that kind of work. The car produced 500RWHP and ran like a champ for that duration.

Unfortunately Tyler had a mishap with the car that resulted in the chassis being damaged beyond repair so he purchased another TTZ and sold the engine/driveline. He purchased several upgrade components to be used in the new build and then flew me up to put her together.

Toot, Toot... does anyone else hear it too? I thought this was going to be a technical-type of VTC post, not some veiled advertisement. I started right off with the headwork. JWT high-tension valvesprings, JWT 500 series camshafts, and MS exhaust manifolds were to be fitted. All of the valves were removed and heads thoroughly cleaned. This time around, Tyler equipped me with a pneumatic die grinder and an assortment of carbide burrs of which were used to fully port the heads. All ports were matched, valves were de-shrouded in the combustion chamber, plug bosses were chamfered to improve flow, and turbine housings were port-matched. I also spent a good bit of time cleaning up the turbine housing scroll, nozzle, and smoothing the nozzle inpingement angle to maximize housing flow. The valves were lapped, new stem seals installed, and JWT high-tension valve springs were fitted. The cams were installed and journal cap mating faces were hand-honed to ensure proper cam-journal clearance. The engine was fully assembled and installed with all of the other bolt-on upgrades and ancillary devices (boost controller, water injection, MASSIVE SMICs, SMIC ducts, etc etc).

Toot, Toot... ok we get it, you know how to build an engine, let's stay focused and get to the subject... "VTCs and all you want/need to know, +++", Yawn Upon initial cranking there was the disctinctive rattle coming from the top end of the engine at the intake cam sprockets which subsided a bit as the engine warmed up. I recognized this noise immediately which I had previously commented on to Tyler as being a possibility with the high tension springs and high-lift cams - I have been dealing with this noise on my personal TTZ for some time and have replaced the intake cam sprockets twice with used sprockets. Unfortunately both times I replaced them I only had about 5-8K miles of service without rattle. I have been dealing with the rattle for quite some time now in my own Z BUT in Tyler's car the rattle was quite a bit more intense and was audible over a wider range of RPM whereas mine would only rattle in an idle condition. I took the front end of his engine apart to verify that everything was assembled properly and all was good. I also took apart the top of the engine to verify that all was good with the valvetrain. It was obvious that the VTCs needed to be replaced to cure this condition and so we proceeded as this noise has not proven to be detrimental to performance or longevity - it is just a very annoying characteristic of old VTCs.. His car performed very well on the dyno - we put down ~550RWHP and GOBS more torque than previously - just a much torque as HP this time around. :) This deserves a "big" Toot, Toot, and an equally big Yawn But there was still that rattle... So, for both our sake, I took it upon myself to dissect the VTCs and figure out a solution to this.

I took apart one of the early model VTCs about 3 weeks ago and studied it for several hours. I was aware of the modifications made by BDE Performance to correct the noise issue and kept the explanation on their website in mind during my study. Bravo, you're off to a good start by referencing BDE information, it's backed by solid research and testing. You should know off the bat that these devices are actually quite complicated pieces of engineering - they use a mechanical structure that is relatively rare - the first of which I have had the opportunity to dissect.

The VTC mechanism uses a helical gear arrangement to provide the ability of advancing the intake camshaft timing by 5 degrees. This results in an advancement of 10 crankshaft degrees (2x since the crank turns twice the rate as the cams - it is not 20 degrees as stated on BDE's website - the diagram in the FSM is showing 10 crankshaft degrees, not camshaft degrees).

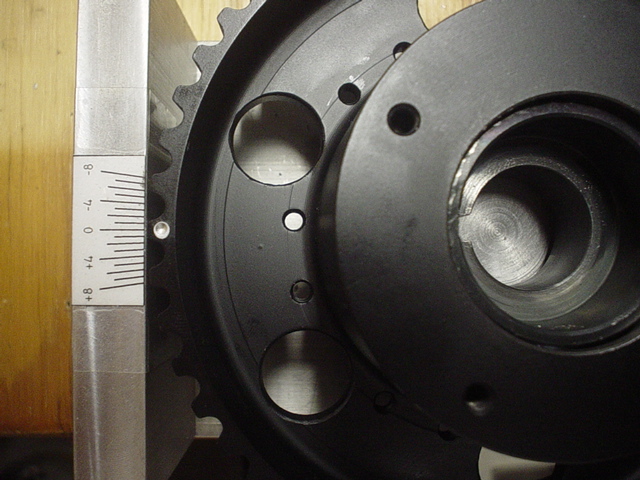

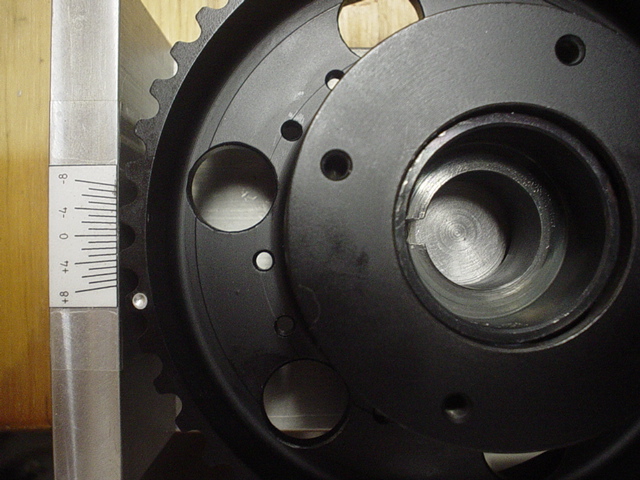

Hmmmm, very disappointing Ash, why you chose to make an issue of this is bewildering to me. No tech paper that I'm aware of has ever talked about camshaft timing in "camshaft degrees" to do so would be nonsense. Here are a couple of pictures of a sprocket I assembled at 0° so I can show that it does indeed advance 10° (20° crankshaft). Note it was also assembled without a spring to facilitate easily advancing it on my fixture. The final picture is the actual timing fixture that I use to set the timing on the rebuilds. Static 0°

Advanced 10°

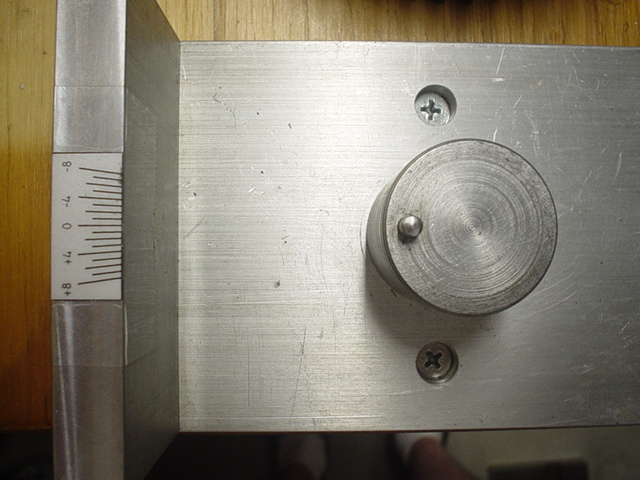

Test fixture

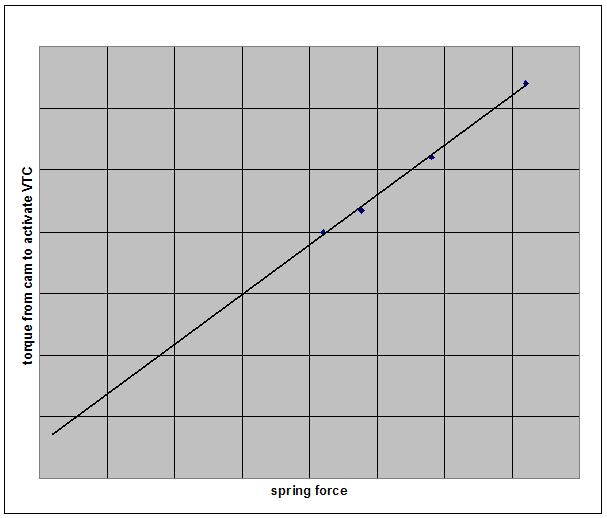

The mechanism uses hydraulic pressure provided by the lubrication system and it can be enabled or disabled by way of a valve which is either open or closed based on a solenoid that the ECU controls. Agreed The intake camshafts in our engines are hollow. They have a bore that runs down the center of them from front to rear. At the front of the cylinder head where the camshaft cap and camshaft seal are, the camshaft has a hole in the side of it connecting to this inner bore. The front camshaft journal has an oil galley port which provides the oil. When the ECU disables the VTC, the solenoid leaves the valve at the back of the camshaft open so oil pressure bleeds out of the cam. When the ECU enables the VTC, the solenoid closes the valve and oil pressure is directed to the front of the camshaft. The bolt that holds the VTC sprocket to the camshaft has a hole through its center which allows this oil pressure to enter the VTC mechanism. Agreed The VTC sprocket has 3 major parts: The outer housing, the piston helix, and the inner camshaft body. The outer housing and inner camshaft body both have helical teeth machined into them which mate to the center piston helix: the piston helix has helical teeth on both its outer and inner faces. The only part that really moves is the piston helix, which is actuated by way of oil pressure. When the oil pressure is applied to the front face of the piston helix, it is pushed back (towards the engine) and due to the helical gear angle, it causes the camshaft to advance by 5 degrees Disagreed, 10° camshaft (20° crankshaft). There is a large internal spring on the backside of the piston helix which will push the piston helix forward when oil pressure is released thereby de-advancing the camshaft back to its base timing. Agreed, and that is all that it does. The outer housing, which also holds the timing belt sprocket, is a seperate part to the piston helix and cam helix. It's position must be constrained so that it doesn't move forward or backward. This is accomplished by way of a thrust bearing face on both the front and rear face of the inner camshaft helix which contacts the front inner wall of the outer housing and the rear thrust bearing contacts the backplate of the VTC housing.. The internal piston helix spring is on the backside of the piston helix. The piston helix, in a non-advanced state, rests on a face at the backside of the front wall of the VTC housing. Because of this, there is a forward bias applied to the outer housing which forces the rear thrust faces together. Disagreed, the rear cover (backplate) is solidly attached to the sprocket body, the piston spring pushes directly on the piston AND the backplate, the spring cannot force the camshaft helix or backplate to contact one another because it does not have any contact whatsoever with the camshaft helix. The camshaft helix floats entirely within the sprocket (more on this later). The rattle from the VTC's will only occur during the non-advanced state - when oil pressure is NOT applied to the piston helix. Agreed, but this seems contrary because a few paragraphs back Ash stated that Tyler's car also makes noise "at various other RPMs," but if the VTC does not make noise during the non-advanced state (from off idle to roughly 5800RPM) where is this noise coming from at various other RPMs? Sounds like atypical VTC noise to me. Here is a picture showing the pieces within the VTC mechanism: On the far left is the outer housing - you can see the helical teeth at the front-end of the part as well as the 4 seperate "stops" for the piston helix. Next item, 2nd from left, is the piston helix. You can see the helical teeth on both the inner and outer face. The inner and outer helical gear angles are opposite of each other. Next item to the right of that is the cam helix, and to the right of that is the rear housing plate. At the top is the piston return spring, bottom left is the piston helix seal, bottom center is the camshaft helix seal, and bottom right is the backplate seal. This next image shows a close-up of the cam helix and the backplate. If you look closely at the backplate (far left), you can see a small circular track around the inner bore where the back lip of the cam helix has worn into it. These two surfaces compose the rear thrust bearing for the outer housing/belt sprocket. It measures right at 0.075" which is a very small thrust face. gut-feeling engineering IMO, yes 0.075" is small in comparison to... say 0.500" but then does it need to be any more? Of all the sprockets I have disassembled I have only found two (from the same engine) that were measurably worn out on this surface. But then every other part of the VTC mechanism was also worn out beyond any sort of being useable. They looked as though sand was run through the oil system causing accelerated wear. The next image shows how the cam helix installs into the piston helix. The assembly on the right is also sitting atop the housing backplate. You can also see the front face of the piston helix, which reveals 6 (black) pins. If you look closely at that piece, you will notice that the teeth on the outer face of the piston helix are split about half-way down the length of the helical teeth. This is because the piston helix actually has two gears face to face. The pins you see at the face of the piston helix have a spring behind each of them which is forcing the top (front) piston helix gear to clamp down to the main piston helix gear/body. Looking even closer at the alignment of the teeth you will see that at the interface between the two, the teeth are slightly offset from each other. This isn't a photographic artifact nor it is some unintentional misalignment made when posing the parts for the picture. They are misaligned for a very good reason and it is called "anti-lash". In order for the three main pieces to come together, the piston helix front gear MUST be raised up off the piston helix main body in order for the teeth to align properly. Because there are 6 springs trying to clamp the two piston helix gears together, once these 3 pieces are assembled, those springs ensure that there is never any gap between the teeth on either the cam helix or the outer body helix..... pretty damn nifty. :) Agreed Now we move to the design issue which causes the rattle, and it is very simple - much simpler than understanding the dynamics associated with the helical bits. The problem comes down to the rear thrust bearing faces. Recall that the main body/sprocket position is constrained by way of the two inner faces that "ride" the inner cam helix - one at the front and one at the rear - I already showed you the two pieces that comprise the rear thrust bearing. It has been determined simply by way of experience that a brand new set of VTC's installed onto an engine with the high-tension springs and high-lift cams will function for ~25K to 30K miles without rattle. Disagreed, several of my tester's cars would make noise within 2500 miles on a new set of sprockets. A brand new set will NOT rattle right off the bat - it takes some time for the noise to occur. Agreed, I will add that any sprocket that has been drained of oil will not make noise immediately upon reinstallation, I suspect the reason is trapped air in the sprocket that provides a compressible cushion and takes time to bleed off. This is the same reason why someone that replaces the front VTC springs experiences a brief period of no noise, air has been introduced into the system.So you have to ask yourself: "If a brand new set doesn't doesn't rattle until ~30K miles, what is changing over that time?" One may think that the internal spring loses its temper and is no longer able to constrain the piston helix against the front stop during the valve closing event Nope, I've cut up brand new sprockets and tested their springs, they all have the same installed pressure, new and old alike., which would "screw" the cam helix "into" the piston helix and "pull" the piston helix towards the engine and off the front stop - only to "spring" back forward at the end of the valve closing event and cause the "clack" you hear. But the fact of the matter is that the angle of the helix is far too small to cause the piston to move because of the torque applied to the cam helix during the valve closing event. Not to mention, those 6 anti-lash springs are causing the piston helix teeth to "bite" into both the cam helix as well as the outer housing helix. If one were to try and apply a torque to the cam helix in an attempt to force the piston helix to move, the teeth of the cam helix would shear off or you would break the shaft you are using to apply said torque. You simply are not going to move that piston helix by way of shaft torque. Absolutely disagreed, and more gut-feeling engineering. I have tested the amount of torque required from the cam to activate the VTC and thereby override the internal spring. No sheared helix teeth nor a broken shaft occured. Please provide proof of your sheared teeth and/or camshaft. Here's a graph showing four measured data points and the linear relationship of camshaft induced torque with respect to spring pressure. The offset from zero is the effect of friction.

So what is really happening to cause the noise? Simple: the rear thrust face wears enough to allow axial movement of the outer housing/belt sprocket. This creates a "jackhammer" effect on the VTC main body, causing it to move back towards the engine, which opens the gap at the rear thrust bearing, and then when it slams back forward, the rear thrust faces collide, causing the noise. Disagreed, if you take the time to look at the forces, besides rotational torque, the only other force acting on the camshaft helix comes from the small front mount VTC spring. This small spring's only function in life is to preload the sprocket relative to the camshaft with it's attached helix and prevent the sudden closing of the very same clearance you are so concerned about when the VTC is activated and pressure builds within the sprocket. I spent several hours studying the VTC I dissected and most of that time was trying to mentally model the physics involved with the helical gears, anti-lash mechanism, and piston return spring - tring to visualize the dynamics of this while in operation, driving the cam and being driven by the cam through its cycle. But in a stroke of chance, I put just the cam helix into the outer housing and fit the backplate into place - when I did this I found that there was about 0.015" of "slop" A.K.A. "clearance" which is necessary for moving and rotating objects to be able to move and/or rotate without bind that allowed me to move the cam helix forward and backward against the thrust faces. So, I went out to the driveway, popped the hood and started the engine. I then took a punch and placed it at the center of the VTC front plate and then applied some force. When I did this, the rattle amplified and I felt a strong "jack-hammer" effect, thus proving that the rattle was actually the noise created when the sprocket's backplate came back into contact with the cam helix thrust face. This is the same effect as applying a stethoscope to the sprocket, if it's making noise of course your going to feel feedback. However, you don't prove where the noise is originating from by doing this. By the way, the "jack-hammer" effect is the VTC piston rapidly hitting its front and rear stops not the measly 0.015" clearance being taken up. So, I proceeded to machine a fix. The image below shows two sets of piston helix and cam helix pieces. The top two are OEM and the bottom two are my modified set. You can see on the cam helix (bottom right) that I have added a larger thrust face - it is 0.175" wide - widened from 0.075". This is the largest you can go while still allowing room for the internal piston helix return spring to slip around it. I also had to machine the back face of the piston helix by the same thickness as the new thrust bearing to allow full motion of the piston helix. Translated: so I decided the best thing to do was turn a good set of sprockets into turds -- they're not even good for cores now. Tyler, my condolences, let me know when you're ready to buy a set of real VTC sprockets that don't make noise and aren't all effed up. Here is another picture: And another with the cam helix installed into the piston helix: In addition, I cut chamfers into the thrust face to allow ample drainback: Extra work needed because now the new thrust surface covers up the original drain slots. And I also widened the return ports on the rear plate. Also, extra work needed because of the wider thrust surface. You can also see the area where I lapped the thrust faces together on the plate on the left: Why was lapping them necessary? I modified the second VTC and turned the faces on both to produce a nice machined appearance - the outer housings were clear powdercoated prior to final assembly and longer bolts were used to allow nuts to be installed/welded to the ends for base cam timing adjustment without having to remove them from the engine. The backplates were TIG welded to the housings rather than bolted or pressed to ensure no leaks, no slippage, and without requirement of a bunch of ancillar hardware to locate/retain the backplate. Even if the mod doesn't work, the welds can be easily machined out on the lathe. Now this is just plain stupid -- you welded it back together? Do you have any idea what heat does to a spring? I honestly expected more from someone like you. The final "acid test" was to install them and see if they rattle, right? :) Well, I'm sure you can imagine that I wouldn't have wasted either of our time carrying on at this length if this were a failure. The beauty of this mod is several fold: They typically rattle only when cold so it was easy to determine if the mod was successful - I simply installed the VTC sprockets, timing belt, and crank pulley (to ensure the belt wouldn't slip off), and crunk her up. The units were even installed completely dry - the parts were cleaned with brake parts cleaner during assembly to remove any oils that could contaminate the TIG welds cudos, dry assembly = metal to metal contact on startup.. They didn't make a peep even from the startup. In that first startup I enabled the VTC via conzult and the engine took on a heavy lope and quickly stalled - indicating that the intake cams were actually advancing. Before installation on the engine, I also machine a "stump" to put into the back of the VTC which I installed a 1/4" hose barb into. I applied air pressure into the VTC to ensure that nothing was binding and the cam helix did shift on both units. It took about 40psi to force the piston to move. So there it is in a nutshell.... Although I'm sure there are some who might think I am trying to smear BDE Performance or trying to "get my foot in the door" at this part of the marketAgreed, but after addressing your entire post, I'm not too concerned. , I assure you that the only reason I even got into playing with the VTCs was for the fact that my customer, Tyler, was displeased by the noise his VTCs were making. Mine were already rattling like SOBs but I have very little time to tend to my own Z - this was just an opportunity to knock two birds out with one stone. I did read BDE's webpage on what they do to VTCs prior to dissecting one but came to find that what they are doing is more of a band-aid to the problem. and what would you call your solution? If mine is a band-aid then yours is the scab that's about to fall off. A stiffer internal spring will prevent the noise, but that is because the spring is applying even more forward bias on the sprocket (piston, not the sprocket) thus preventing the rear thrust faces to jackhammer. Unfortunately the stiffer spring is going to cause accelerated wear on that small thrust face in the OEM design. Prove it -- as stated earlier, this spring force has absolutely no effect on the camshaft helix, and it cannot cause accelerated wear because of this. The upgrade I am doing doesn't use any new parts - I am only increasing the rear thrust bearing face and removing the axial slop - I am also using the small OEM front VTC spring that is located just behind the front cover plate rather than the JWT "increased rate" spring Ditto, after testing JWT VTC springs, I cannot recommend them at all.. This upgrade should produce a service life that will likely exceed the service life of the car, so, lifetime warranty would be easily offered.. If you are inferring that my one-year warranty is a disguised admission that they will fail at some point after the warranty expires, then I say "IF" any of my rebuilds were to ever make noise, I would be the first person that wants to know, and then find the reason behind it and address it. This is called "customer service" in case you aren't familiar with the term. But I don't have to worry about such problems because I have done the research and testing to provide a solid product.To be clear to everyone, VTC noise is caused by a combination of rotational torque imparted by the valve springs onto the camshaft, accelerating the cam and overpowering the VTC piston and its spring via the VTC helices. Valve springs with more installed pressure than stock will push harder on the camshaft and increase this effect.

Also acting on the VTC piston is residual oil pressure that builds in the sprockets because the check valves in the back of the cams cannot flow enough oil to relieve all of the pressure. This effect can easily be confirmed in cold start situations with heavy weight oils. Camshafts with higher lifts have a small contributing effect which gives the lobes more leverage to over-rotate the cam, but this is minimal compared to the other two components. All of these forces need to first overcome friction before any noise will occur and this is a huge variable that most likely diminishes as all of the parts wear together. This explains why some stock engines with no valve train modifications can and do exhibit VTC noise.

|