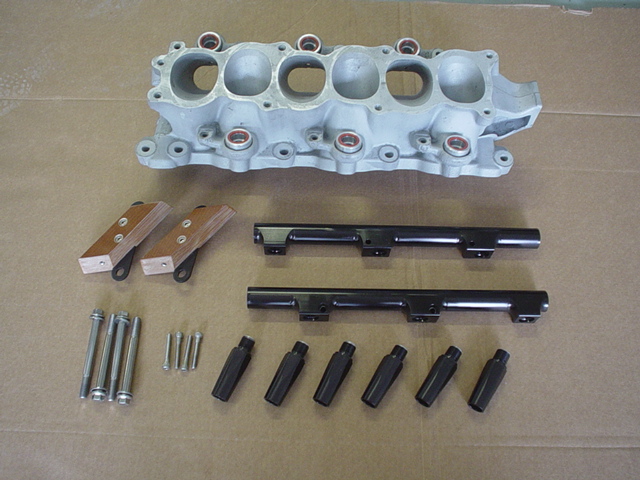

| I started this project because side-feed injectors are maxed out at 850cc/min limiting overall HP potential, while top-feeds are available in 1000, 1200 and 1600cc/min AND there are versions that use better technology such as Peak and Hold coils and lighter internals for quicker response times and higher duty cycles than side-feeds could ever dream of. Without a fuel rail though, utilizing top-feed injectors has been entirely a custom endeavor with a VG engine but I'm almost ready to release the following BDE fuel rail kit for public consumption and I can finally begin forward progress on my own engine again. Here's a nice little mock-up showing the entire kit with core lower plenum. Note that the injectors aim into the ports at the exact same angle as stock ones, so the electrical connections do not interfere with the intake valvecovers.

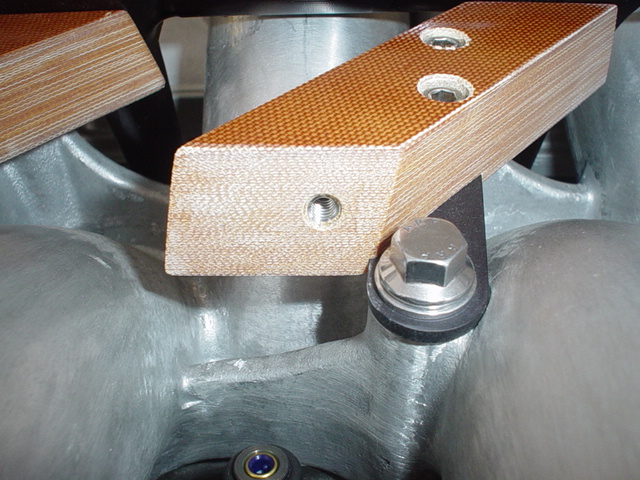

Top view, the brown blocks are a Phenolic composite that will isolate the fuel rails from any metal to metal contact and minimize heat conducted into the fuel.

Complete kit broken down.

Fuel rails are extrusions with a 1/2" bore and -6 AN o-ring ports at all fluid flow connections. The bottoms are machined to allow them to sit low on the upper plenum and maximize underhood clearance.

-6 AN o-ring ports

Mounting blocks

Injector stacks

Installed on upper plenum. Note several of the cast bosses for the original throttle cable cover need to be removed for clearance.

Close-up of clearance to upper plenum ports (it's about 0.060" [1.5mm]).

Mounts and ARP upper plenum bolts

Phenolic mounting block is heli-coiled

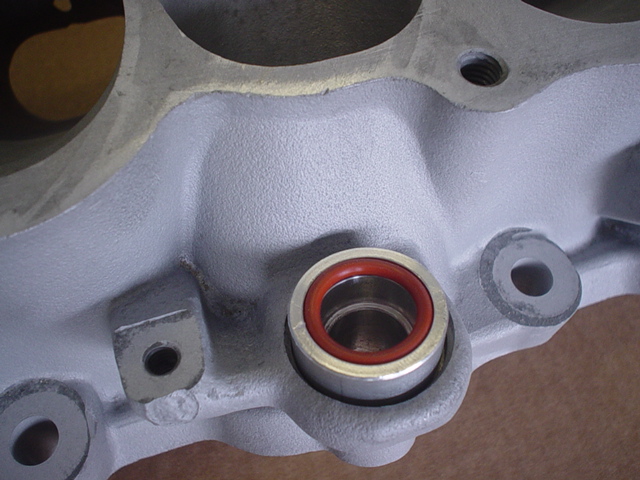

lower plenum with adapter bungs, these are installed with a slight press fit and glued with hi-temp epoxy. The plenums do need to be machined by me to fit the bungs.

This silicone o-ring serves as a cushion and to prevent the injector from metal to metal contact with the bung, the injectors still seal inside the bung with their own o-ring.

injectors installed

crossover tube mods yet to be completed, basically just the Idle air valve inlets need to be relocated. No notches required for clearance to the rails though.

-8 AN return lines for parallel setup, there's probably a hundred different ways to plumb these things, but at least a parallel system is now a snap.

|