For years ppl have been struggling with bearing failures due to distortion of housing bores associated with excessive combustion pressures and loads. Main bearings taking a bunch of extreme beatings on assemblies making above 800+hp. Fretting of the main registers occurs, flexing of the stock one piece girdle causes housing bore dimensions to distort, the issues keep coming. For those that are in the upper area of producing hp and tq look no further because the solution to the problem is finally here.

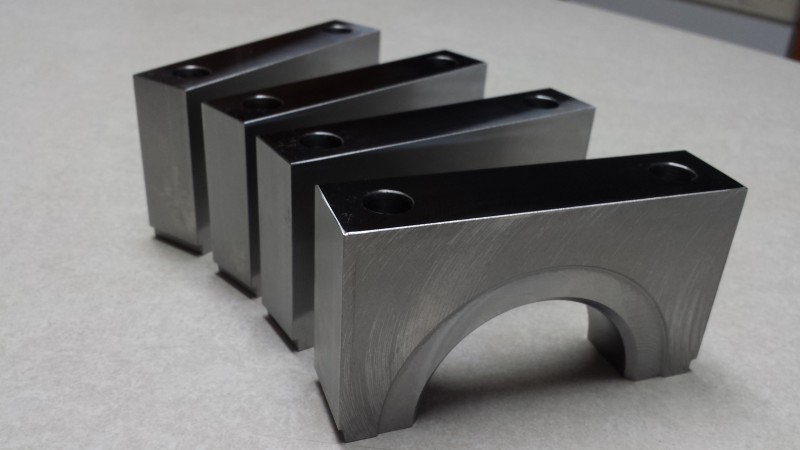

Through months of work and in house development I finally have the solution to keeping the crankshaft located and maintained. That solution is my new billet main cap and girdle system. EPR Billet Steel Main Caps offer excellent strength at a reasonable cost. They’re made from precision-machined (CNC) high strength steel (90,000 tensile strength material far exceeding the OEM cast core component), which has the proper balance of strength and flexibility to allow transfer of increased shock loads to the crank and bearings. These main bearing caps will improve your engine performance and reliability by eliminating main cap walk and reducing main bearing bore distortion. The girdle plate made of solid sheet steel is cnc laser cut then put through a bending process to not only strengthen the girdle plate but also give the assembly what it needs for the proper clearance of the crankshaft counterweights. Girdle plates are also chemically etched clean then black zinc plated to give the unit a nice uniform and clean look and feel. This setup obtains current dimensions so you can use the ARP hardware offered currently on the market. This is a complete solution to tackling flex and distortion issues associated with a single piece cast girdle setup. Benefits/Characteristics

• CNC machined

• Manufactured from billet steel

• Stabilizes the entire crankshaft rotating assembly If you are building a VG30 to the 800+hp or more this is the setup that will ensure your engine sustains the abuse time and time again. This system is better suited to locate the crankshaft for any application and all HP figures but consumers aiming for high power production this setup is an absolute must. Line bore/honing is required for proper fitment. Please consult your preferred machine shop for pricing and details or you can send your block to me for proper machining and setup for this system. ALL ASSEMBLIES ARE MADE RIGHT HERE IN THE USA!!!! Pricing - $1200+ shipping. 3-6 weeks lead time due to CNC scheduling and orders

|