It's most likely (99%) the clutch pedal adjustment!

I had a Clutch Masters Cyclone 3.5 installed and it slipped like hell,

especially after warming up. It was down to the fluid going hydroscopic

when the clutch pedal was adjusted too high! (Basically it means the fluid

got hot and expanded throwing out the clutch and making it disengage a

little).

If you have a Pre 1992 300 then your clutch master cylinder may need

changing - The later cylinder has a bigger bore for the fluid and helps

to solve this problem. The Nissan service bulletin recommends changing

this part and the clutch return spring. Only replace these parts if clutch

adjustment fails to fix the problem.

Adjust your clutch pedal so that the engagement is around the middle

(between clutch up and down)... After many adjustments I found the best

position was 1/3 way from the floor. This gave quick engagement and correct

disengagement without crunching the gears, it also cured the hydroscopic

problem.

Advice:

1. If it disengages near the top it's adjusted to high and it may well

slip, especially after warming up.

2. Too near the bottom and it may not disengage correctly and crunch

the gears or even lockup, especially when cold.

3. If the clutch position changes when the car warms up and is exaggerated

when stopping at lights, (it can also feel more hard to press) then it's

still too high.

4. Just two turns on the clutch adjustment nut can make a big difference.

5. Remember how far you've turned the nut and what the results were

in case it needs several adjustments. If only I had done this!

Jez

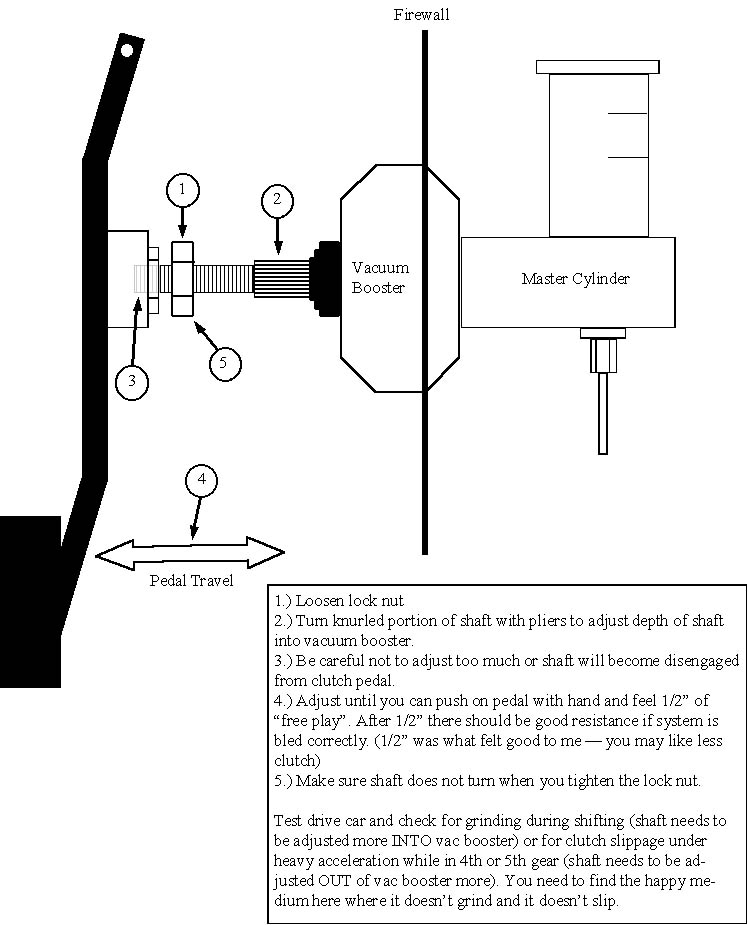

The procedure is best done by laying on your back with your head placed

just below the clutch pedal (so yeah, a good idea to shake the crud off

those floor mats prior to this drill). With light in hand, look towards

top of clutch pedal. There is a clevis with a rod (pointing towards front

of car) and jamb nut attached. Loosen the jamb nut (14mm). See below for

which way to rotate adjusting rod. Note that rod rotation direction is

when viewed from the DRIVERS SEAT perspective.

BEHAVIOR: Engages too close to floor, may grind when putting into 1st

or reverse.

REMEDY: rotate rod clockwise (rod is unscrewed from clevis making it

longer).

BEHAVIOR: Engages too far away from floor, slipping may also be present.

REMEDY: rotate rod counter clockwise (rod is screwed into clevis making

it shorter).

Working room is quite tight and a pair of long needle nose pliers work

nicely for rotating the rod. A little rotation goes a long way so don't

rotate more than several revolutions between test drives. If things are

getting worse you are probably rotating the rod in the wrong direction.

It is sometimes difficult to see if the rod is even turning since you can

rotate it only about 1/10 revolution at a time (due to aforementioned tight

working quarters). Take a thick tip felt pen and place a few marks on the

shaft to help monitor rotation progress. And don't forget to tighten the

jamb nut when through.

Maj

Zedhead